GrandPack DJ-50D: The Ultimate Top-Opening Cartoning Machine for Modern Production

In today's competitive market, efficiency and reliability in your packaging line are not just advantages—they are necessities. Manual or semi-efficient packaging processes can create bottlenecks, increase labor costs, and lead to inconsistent quality, hindering your business's growth. The GrandPack DJ-50D Cartoning Machine is the definitive solution, engineered to transform your end-of-line packaging from a challenge into a competitive edge. This advanced, vertical top-opening cartoning machine is specifically designed for businesses that demand flexibility, precision, and a rapid return on investment, automating your entire box forming, loading, and sealing process with unparalleled ease.

At GrandPack, we understand that a "one-size-fits-all" approach doesn't work. That's why we've developed the DJ-50D cartoner—a compact powerhouse that caters to the dynamic needs of modern manufacturing. Whether you're a growing startup or an established enterprise looking to optimize a specific production line, this machine delivers the automation and quality you need to scale effectively.

Core Features of the GrandPack DJ-50D Cartoner

Flexible Design for Growing Businesses

The DJ-50D is ideal for packing small to medium quantities in various box sizes. It’s compact, cost-effective, and easy to integrate into existing production lines.Quick Changeovers for Multiple Box Sizes

Switching box sizes is fast and simple, making it perfect for manufacturers handling many SKUs or frequent production changes.Durable 304 Stainless Steel Construction

Built entirely with 304 stainless steel, the machine resists corrosion, meets GMP standards, and is easy to clean—perfect for pharmaceutical and food applications.User-Friendly Touchscreen Control

An advanced PLC system with a full-color touch screen makes setup and adjustments easy. Operators benefit from a simple interface, quick training, and real-time monitoring.

Technical Specifications

| Feature | Model DJ-50 | Model DJ-50D |

|---|---|---|

| Production Speed | 20–50 boxes per minute | 26–65 boxes per minute |

| Paper Box Size Range | L(20–70) × W(20–70) × H(45–280) mm | L(26–91) × W(26–91) × H(59–364) mm |

| Paperboard Quality | 250–350 g/m³ | 250–350 g/m³ |

| Motor Power | 1.5 kW | 1.5 kW |

| Power Supply | Single Phase 220 V 50/60 Hz | Single Phase 220 V 50/60 Hz |

| Machine Noise Level | ≤ 80 dB | ≤ 80 dB |

| Required Air Pressure | 0.5–0.8 MPa | 0.5–0.8 MPa |

| Air Consumption | 260 L/min | 260 L/min |

| Machine Dimensions | (L)1100 × (W)1500 × (H)1700 mm | (L)1100 × (W)1500 × (H)1700 mm |

| Machine Weight | Approx. 450 kg | Approx. 550 kg |

Hot-melting machine, paper cup selection

Machine Video

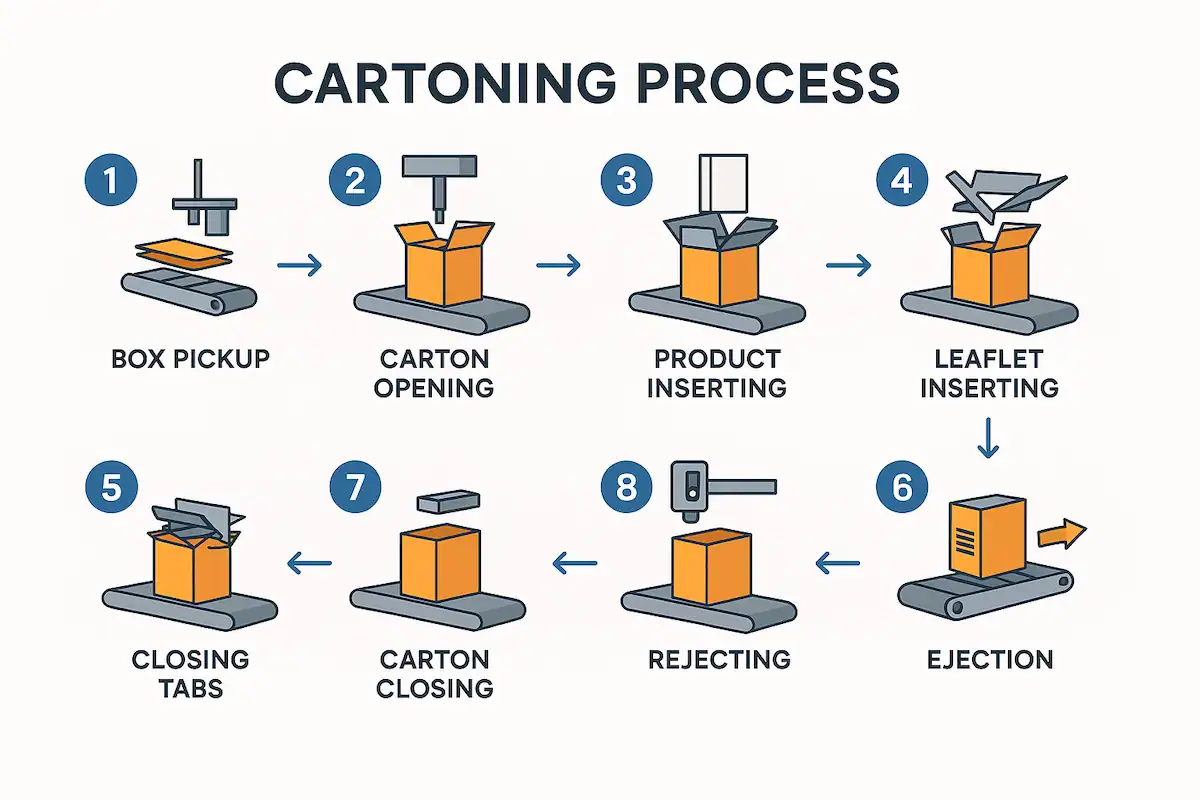

The DJ-50D executes a flawless, repeatable sequence to create perfectly formed and sealed cartons every time. This can be configured as a semi-automatic cartoning machine with manual product loading or a fully automatic cartoning machine when integrated with an upstream automatic in-feed system.

Versatile Cartoning Machine Applications Across Industries

- Pharmaceutical and Nutraceuticals: Perfectly suited for packing round or square bottles of oral liquids, vials, and blister packs. The top-load orientation ensures that delicate products are handled gently. Optional leaflet inserters ensure that all necessary documentation is included in every box.

- Food and Beverage: Automate the packaging of bulk snacks, granola bars, tea bags, coffee pods, and other loose items. The vertical loading process is perfect for products that need to be settled into the carton. The 304 stainless steel construction meets stringent food-grade hygiene standards.

- Cosmetics and Personal Care: From jars of cream with inner liners to tubes of lotion and lipstick, the DJ-50D provides a pristine, professional finish to your packaging. It can handle the delicate and often irregularly shaped containers common in the cosmetics industry with precision.

- Adhesives and Chemicals: Effectively package products like tubes of 502 glue or other bottled chemicals, where a vertical orientation for stability and secure sealing is paramount.

Why Choose a GrandPack Cartoning Machine?

Selecting the right automation partner is as critical as selecting the machine itself. At GrandPack, we are more than just a manufacturer; we are your dedicated partner in packaging excellence. Our philosophy is built on three pillars:

- Innovation in Action: We don't just build machines; we engineer solutions. The DJ-50D is a testament to this, integrating an advanced PLC system with a user-friendly HMI to put sophisticated control at your fingertips.

- Uncompromising Quality: Durability is not an option. With a robust 304 stainless steel frame, our machines are built to withstand the rigors of continuous operation, ensuring hygiene and longevity.

- Customer-Centric Flexibility: We designed the DJ-50D for high-mix, low-volume production. We recognize that your product dimensions change, and your packaging needs to adapt quickly. Our rapid, tool-less changeover design means you spend more time producing and less time retooling.

Mechanical details

Paper box

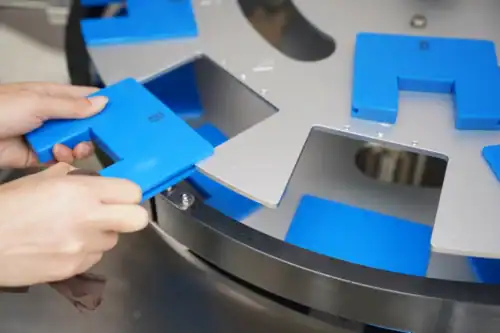

Manual installation of cartoning machine

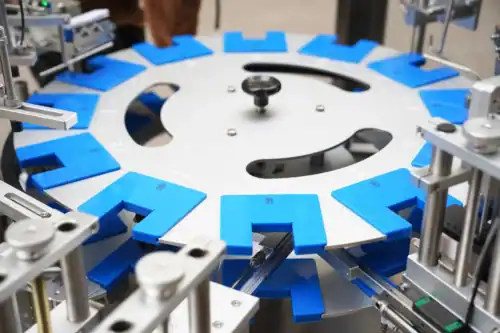

Cartoning machine turntable

Cartoning machine infeed

Control screen-cartoning machine

Inspection-Cartoning Machine

Unwavering After-Sales Service and Support

When you invest in a GrandPack machine, you are investing in a long-term partnership. Our commitment to your success extends far beyond the point of sale. We provide:

- Expert Consultation: Our team works with you to understand your needs and ensure the machine is configured perfectly for your application.

- Installation & Training: We offer comprehensive on-site installation and operator training to get your team up to speed quickly and safely.

- Responsive Technical Support: Our dedicated technical support team is available to help you troubleshoot any issues and minimize downtime.

- Readily Available Spare Parts: We maintain a full inventory of critical spare parts to ensure your machine keeps running smoothly for years to come.

Are you ready to eliminate packaging bottlenecks and unlock new levels of efficiency? It's time to automate with a solution that is as flexible and ambitious as your business.

FAQs for Cartoner Machine

1. What is the main advantage of a top-opening (vertical) cartoner versus a horizontal one?

A top-opening cartoner is ideal for products that are unstable or difficult to push, such as bottles, jars, or loose-fill items. The vertical orientation uses gravity to assist in loading the product neatly into the carton, which can be gentler and more efficient for these types of goods.

2. How long does it typically take to change over the machine for a different box size?

The GrandPack DJ-50D is designed for rapid changeovers. While the exact time can vary based on the complexity of the size change, an experienced operator can typically complete the entire process in under 30 minutes, thanks to its user-friendly adjustment points and PLC-stored recipes.

3. Is the machine difficult for our staff to operate?

Not at all. The DJ-50D features an advanced PLC control system with a color touch screen interface that is highly intuitive. We provide comprehensive training during installation to ensure your team is confident in operating the machine, performing changeovers, and conducting basic maintenance.

4. Can this machine be integrated into our existing production line?

Absolutely. The DJ-50D is designed with integration in mind. It can be configured as a standalone station with manual feeding or be seamlessly connected to upstream equipment (like fillers or wrappers) and downstream equipment (like case packers or palletizers) to create a fully automatic packaging line.

5. What kind of maintenance does the DJ-50D cartoner require?

Routine maintenance is straightforward and designed to ensure maximum uptime. It includes daily cleaning, periodic lubrication of moving parts, and inspection of wear-and-tear components like suction cups. We provide a detailed maintenance schedule and manual with every machine.

6. What is the difference between the DJ-50 and the DJ-50D models?

The primary difference is the size range of the cartons they can handle. The DJ-50D model is more versatile, accommodating a larger box size up to 120mm in length and width, while the standard DJ-50 handles boxes up to 70mm. Both models share the same core technology, speed, and quality construction. We can help you choose the model that best fits your product dimensions.