Your Guide to the Top 11 Cartoning Machine Manufacturers

Which film should I choose to unleash the performance of the side sealer?

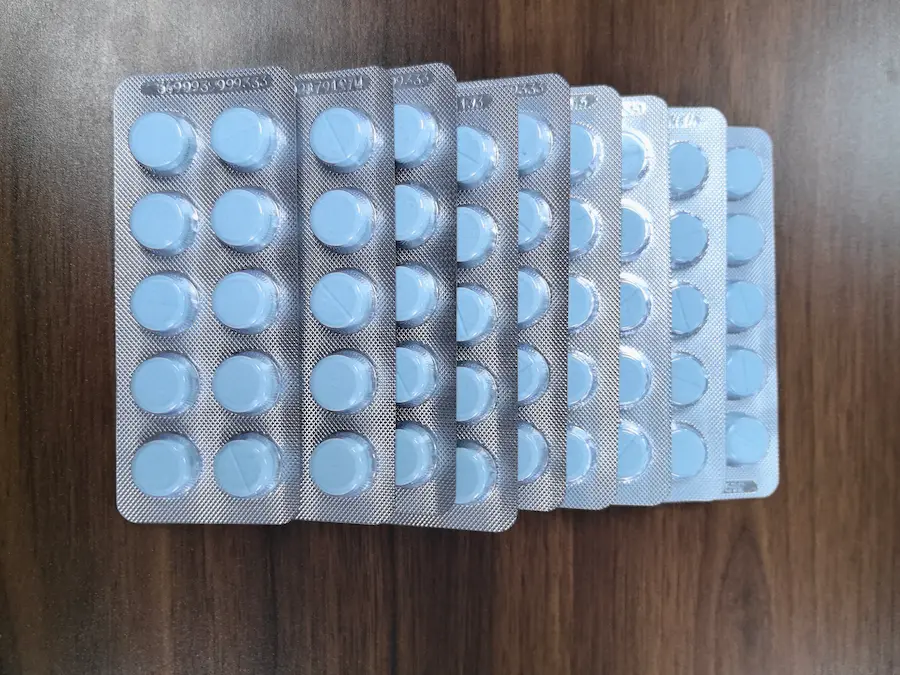

The Plastic Prison Break? Unlocking the Secrets of Pill Lifespan in Blister Packs

Introduction

Ever stared at a capsule blister pack, wondering just how long that little dose of health will remain potent within its plastic and foil confines? It’s a question that weighs on the minds of patients and is a constant focus for pharmaceutical manufacturers. After all, the integrity and efficacy of medication are paramount. So, how long does a pill in plastic last? Let's peel back the layers of this critical aspect of pharmaceutical packaging and explore the fascinating science behind it.

At the heart of this discussion lies the capsule blister pack, a seemingly simple innovation that has revolutionized how we protect and consume medications. Unlike their loose counterparts rattling in a bottle, tablets and blister pack capsules reside in individual cavities, each a miniature fortress designed to ward off the environmental elements that can degrade their quality.

The Mighty Blister: A Micro-Environment of Protection

Think of a blister tablet nestled within its plastic shell as being in its tiny vault. These individual compartments, typically formed from thermoformed plastic like PVC (polyvinyl chloride) or PVDC (polyvinylidene chloride), and sealed with a foil laminate (often aluminum), create a barrier against a host of potential threats:

- Moisture: Humidity is a notorious enemy of many medications, causing them to degrade, lose potency, or even change their physical form (becoming sticky or crumbly). The sealed cavities of a capsule blister pack drastically limit moisture permeation.

- Oxygen: Oxidation can chemically alter drug compounds, reducing their effectiveness. The foil backing, in particular, provides an excellent oxygen barrier.

- Light: Certain medications are sensitive to UV or visible light, which can trigger degradation. The opaque nature of some blister pack materials, combined with the foil backing, helps shield the contents.

- Physical Damage: The rigid plastic cavity offers a degree of physical protection against crushing or abrasion, ensuring the tablet or capsule remains intact.

- Contamination: By individually sealing each dose, blister packs minimize the risk of microbial or other forms of contamination that could occur if multiple pills were stored together in a bottle.

This robust protection is precisely why tablets in blister packs often boast a longer and more reliable shelf life compared to those stored in multi-dose bottles after they are opened.

The Expiration Date: A Promise Sealed in Plastic

The golden rule for any medication, regardless of its packaging, is to adhere to the expiration date printed on the label. This date isn't arbitrary; it's the result of rigorous stability testing conducted by pharmaceutical companies. These studies assess how the drug product degrades over time under various controlled conditions (temperature, humidity, light exposure) while housed in its intended packaging, which, for many solid oral dosages, is the blister tablet format.

The expiration date signifies the period during which the manufacturer guarantees the drug will maintain at least 90% of its original potency and meet other specified quality attributes when stored in its original, unopened packaging. This is a crucial point to understand. The protective environment of the capsule blister pack is integral to achieving that stated shelf life.

When the Fortress Walls Come Down: Life After the Break

So, how long does a pill in plastic last? Ideally, until its expiration date, as long as the packaging remains intact and it's stored according to the label's instructions (usually in a cool, dry place). But what happens when a pill is removed from its protective blister pack environment?

Once a tablet or capsule is liberated from its cavity, it loses the primary defenses against moisture and oxygen. The rate of degradation can significantly increase. Factors such as the ambient humidity and temperature will play a much more direct role in its stability.

The question, "How long do tablets last out of a blister pack?" doesn't have a definitive answer. It depends heavily on the specific medication, the prevailing environmental conditions, and the duration of exposure. However, the consensus among pharmacists and pharmaceutical professionals is that once a pill is removed from its blister pack, it should be taken as soon as practically possible and should not be stored for later use, especially not for extended periods.

Can you remove pills from a blister pack in advance for convenience? While it might seem easier to have your doses pre-arranged, this practice is generally discouraged due to the increased risk of degradation and potential confusion about dosage and expiration dates. It's always best to remove a pill from its blister tablet packaging immediately before you intend to take it.

Bottle vs. Blister: The Packaging Paradigm

For some over-the-counter medications and older formulations, bottles remain a common packaging choice. However, for many prescription drugs, particularly those sensitive to environmental factors, the capsule blister pack has become the preferred standard.

Compared to a multi-dose bottle that is repeatedly opened and closed, exposing all the tablets or capsules to the ambient environment each time, a blister pack pill format offers superior protection for the remaining doses. Every untouched pill remains sealed in its protective bubble.

Therefore, the answer to "Do pills go bad if not in the bottle?" is nuanced. Pills specifically packaged in blister packs are often intended to benefit from that individual protection. Removing them and storing them loosely, even in a different bottle, compromises their stability and can lead to premature degradation.

The Science Behind Stability: Why Packaging Matters

The effectiveness and safety of a medication hinge on its chemical stability. Active pharmaceutical ingredients (APIs) can undergo various degradation pathways, including hydrolysis (reaction with water), oxidation (reaction with oxygen), photolysis (breakdown by light), and thermal degradation (breakdown by heat).

High-quality pharmaceutical packaging, such as well-designed capsule blister packs, is engineered to minimize these degradation processes. The choice of plastic film with low moisture vapor transmission rates (MVTR) and foil laminates with excellent barrier properties is are critical consideration in packaging development.

Ensuring the Seal: The Role of Advanced Packaging Machinery

The protective benefits of a blister tablet are only realized if the packaging is flawlessly executed. This is where advanced pharmaceutical packaging machinery plays a pivotal role. High-speed blister packaging machines, like those offered by Grand, are essential for creating consistent, hermetically sealed blisters.

These sophisticated machines precisely form the cavities, accurately place the blister pack capsules or tablets, and then apply and seal the lidding foil under controlled conditions. The integrity of this seal is paramount to maintaining the protective micro-environment within each blister.

Grand: Powering Pharmaceutical Packaging Excellence

At Grand, we understand that the quality of pharmaceutical packaging is intrinsically linked to the efficacy and safety of the medication it contains. That's why our tablet production line and capsule production line solutions are engineered with a focus on precision, reliability, and compliance with the most stringent industry standards.

Our comprehensive offerings include state-of-the-art capsule filling machines that ensure accurate and consistent dosing, high-speed blister packaging machines that create robust and protective seals, efficient cartoning machines for final packaging, and automated case packers and palletizers to streamline your end-of-line operations. By providing a complete and integrated solution, Grand empowers pharmaceutical manufacturers to optimize their production processes and deliver high-quality medications in packaging that preserves their integrity until the moment of use.

Choosing the right packaging machinery partner is crucial for ensuring the stability and shelf life of your pharmaceutical products. Grand's commitment to innovation and quality makes us a trusted partner in this critical aspect of drug manufacturing.

Conclusion: Respecting the Plastic Prison for Pill Longevity

So, returning to our initial question: "How long does a pill covered in plastic last?" The answer, while primarily tied to the printed expiration date, is deeply intertwined with the protective capabilities of the capsule blister pack. These ingenious little fortresses play a vital role in shielding medications from environmental aggressors, thereby preserving their potency and safety.

Respecting the integrity of the blister pack is paramount. Removing pills prematurely exposes them to conditions that can accelerate degradation, potentially impacting their effectiveness. By understanding the science behind blister packaging and investing in high-quality packaging solutions, like those offered by Grand, pharmaceutical manufacturers can ensure that their medications reach patients in the best possible condition, ready to deliver their intended therapeutic benefits, right up to their expiration date.

FAQs: About Grand's Blister and Capsule Production Lines

- How does Grand's blister packaging machine ensure a consistent and reliable seal for capsule blister packs, which is crucial for maintaining shelf life? Grand's blister packaging machines are engineered with precision sealing mechanisms that apply consistent heat and pressure across the entire sealing area. Our advanced control systems allow for precise adjustment and monitoring of these critical parameters. Furthermore, we utilize high-quality sealing die materials and offer options for vision inspection systems to detect any defective or incomplete seals, ensuring the integrity of each individual blister cavity and maximizing the protective barrier for the blister pack capsules.

- Can Grand's complete capsule production line, including the blister packaging machine, handle different types of blister materials (e.g., PVC, PVDC, cold-form aluminum) and various capsule sizes? Yes, Grand's capsule production line is designed for flexibility. Our blister packaging machines are capable of processing a wide range of thermoforming and cold-forming materials, including PVC, PVDC, PET, PP, and aluminum laminates. The machines feature adjustable tooling and format parts that can be easily changed over to accommodate different capsule blister pack formats and various capsule sizes (from the smallest to the largest), providing versatility for different product requirements.

- What features does Grand's capsule and blister packaging equipment incorporate to meet stringent pharmaceutical cGMP requirements and ensure product safety and quality? Grand's pharmaceutical machinery is designed with cGMP compliance as a core principle. Our capsule filling machines and blister packaging machines feature hygienic designs with smooth, easily cleanable surfaces and minimal particle generation. They are constructed using FDA-approved materials. We also offer options for enclosed processing areas, laminar airflow systems, and integration with process monitoring and data logging systems to ensure full traceability and compliance with regulatory guidelines for product safety and quality throughout the capsule blister pack manufacturing process.

Develop Your Business with Grand