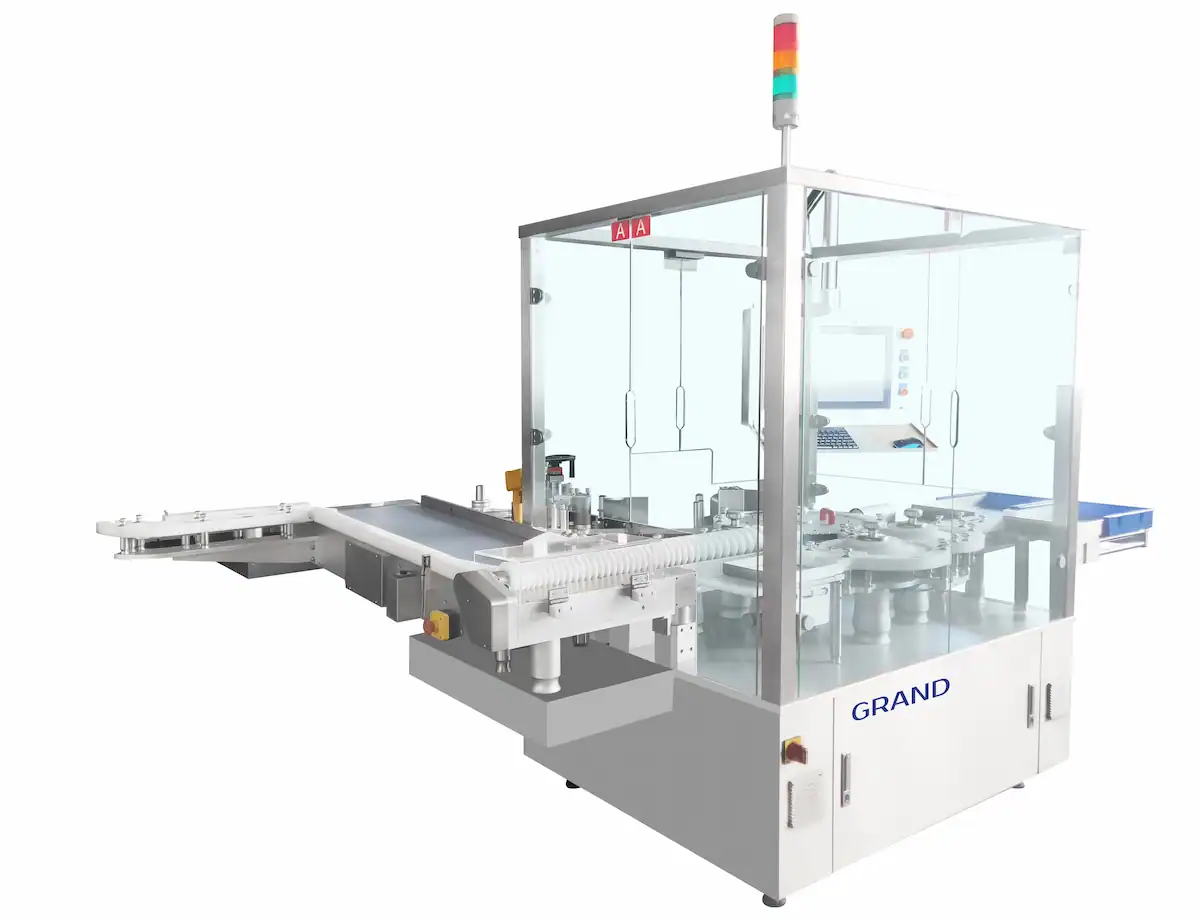

The GRAND High-Speed Rotary Bottle Labeling Machine-Precision, Speed, and Reliability:

The pharmaceutical and cosmetic industries demand unparalleled precision and efficiency, especially when handling small, delicate containers like ampoules and vials. Introducing the GRAND High-Speed Rotary Bottle Labeling Machine—a state-of-the-art solution engineered to meet the most stringent production requirements. This advanced automatic labeling machine seamlessly combines cutting-edge technology with robust design, delivering superior labeling accuracy at a remarkable speed of up to 500 bottles per minute. It is the definitive choice for any operation seeking to optimize its bottle labeling equipment for small, challenging products.

Develop Your Business with Grand

Broad Application Range

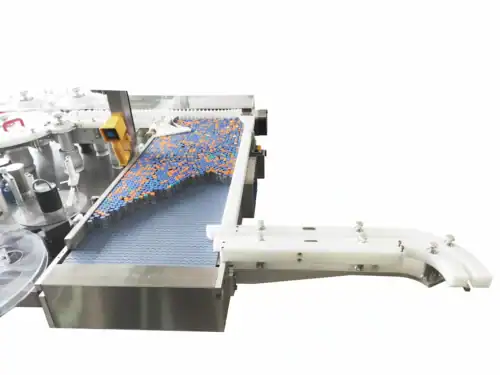

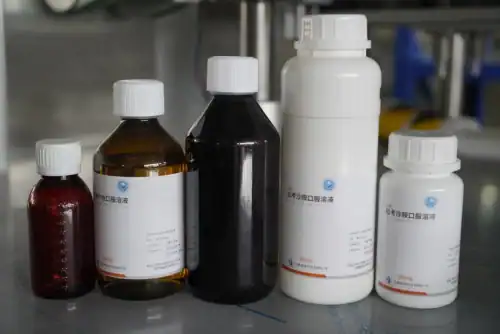

The versatility of the GRAND High-Speed Rotary Labeling Machine makes it suitable for a wide range of industries and products. Its core design is optimized for small, round items, making it perfect for:

Pharmaceuticals: Ampoules, penicillin vials, sterile water bottles, and other medicine containers.

Cosmetics: Small cosmetic sample bottles, essential oil bottles, and fragrance vials.

Chemicals: Small laboratory bottles and reagent vials.

From pharmaceuticals that require strict adherence to regulatory standards to consumer goods that demand a flawless presentation, this label dispenser ensures every product meets your quality and efficiency goals.

Technical Specifications: Precision at a Glance

| Parameter | Specification |

|---|---|

| Bottle Dimensions | Diameter: Φ10-30mm |

| Labeling Speed | Up to 500 bottles/minute |

| Labeling Accuracy | ±0.5-1.0mm |

| Working Air Pressure | 0.4-0.7 Mpa |

| Power & Consumption | 220VAC±10% / 50Hz / 2.8Kw |

| Dimensions (L×W×H) | 2208mm × 1420mm × 1948mm |

Labeling machine features

Unrivaled Performance for Small Cylindrical Containers

This machine is meticulously designed to overcome the common challenges of handling small, round, and potentially unstable containers. Unlike conventional linear systems, our rotary design ensures each bottle is precisely positioned and controlled throughout the labeling process. The vertical conveying and screw dispensing system is a game-changer, providing a stable, upright feed for even the smallest vials and ampoules. This prevents tipping and ensures a smooth, uninterrupted flow of products, maximizing your output and minimizing waste.

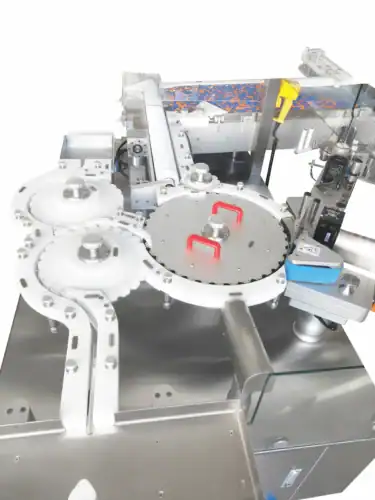

High-Speed Rotary Design for Flawless Application

At the heart of our machine is the rotary roller turntable, a marvel of engineering that enables continuous, high-speed labeling with pinpoint accuracy. The three-point positioning system on the turntable holds each bottle securely in place, guaranteeing a consistent label application with a tolerance as low as ±0.5-1.0mm. This level of precision is critical for industries where compliance and aesthetics are paramount. As bottles are seamlessly transferred from the conveyor to the turntable, they are labeled in a continuous motion, eliminating the stops and starts that can compromise accuracy and slow down production.

Advanced Vision and Rejection System

Quality control is built directly into our machine. An integrated vision inspection system provides real-time monitoring of every labeled product. This sophisticated system can be configured to perform a variety of checks, including:

Label Presence: Verifying that a label has been applied.

Label Position: Ensuring the label is aligned correctly.

Missing Code Detection: Checking for unprinted or illegible batch codes and expiration dates.

Print Content Verification: Confirming the printed information matches specifications.

Why Choose GRAND Labeling Machines?

When you invest in a GRAND label applicator, you are choosing more than just a piece of equipment; you are partnering with a brand dedicated to excellence. Our machines are the result of years of research, development, and real-world application, engineered to provide maximum uptime and a low total cost of ownership.

- Superior Engineering: Every GRAND machine is constructed from high-quality, durable materials, including robust stainless steel, ensuring a long service life and easy maintenance. The intuitive design and real-time monitoring system minimize the need for operator intervention and simplify troubleshooting.

- Cutting-Edge Technology: We continuously innovate to stay ahead of industry demands. Our rotary systems and advanced vision technology represent the pinnacle of automatic labeling machine design, providing a competitive edge in your production line.

- Commitment to Service: We stand by our products with comprehensive after-sales support. From installation and training to routine maintenance and troubleshooting, our team is committed to ensuring your machine operates at peak performance for years to come.

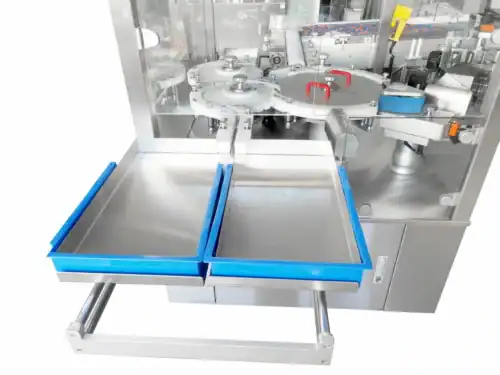

- Maintenance & After-Sales Service

Maintaining your labeling machine is crucial for preserving its high-speed performance and extending its lifespan. The GRAND Rotary Labeling Machine is designed for straightforward maintenance, with easily accessible components and a system that provides real-time status and alarm information. Our service commitment includes: Detailed Manuals,Technical Support, Spare Parts Availability,Customized Service Plans.

Frequently Asked Questions

1. Can this machine handle different bottle sizes?

Yes, the machine is designed for bottles with a diameter of 10-30mm. Changing the bottle size may require a quick adjustment or, in some cases, a replacement of the feeding screw and turntable, which can be done efficiently.

2. How fast can it label bottles?

It can label up to 500 bottles per minute in a continuous operation, making it ideal for high-volume production.

3. What is the labeling accuracy?

The machine provides high-precision labeling with an accuracy of ±0.5-1.0mm, ensuring a professional and consistent finish on every product.

4. Can it print codes on the labels?

Yes, it can be equipped with an optional hot stamping, thermal transfer, or inkjet printer to apply dates, batch codes, or other variable data simultaneously with the labeling process.

5. Is the machine easy to operate?

The machine features a user-friendly interface that provides real-time information on its operating status and any alarms, making it easy for operators to manage and monitor.