Fully Automated Candy Packaging Line

In the competitive confectionery market, efficiency, accuracy, and presentation are paramount. Manual or semi-automated processes can lead to inconsistent product weights, higher labor costs, and slower production speeds, hindering your growth potential. Grand presents the ultimate solution: a fully integrated, turnkey Candy packaging production line designed to take your operation to the next level.

Engineered for seamless performance, this complete system handles everything from precise weighing to perfect boxing, sealing, and labeling. By integrating state-of-the-art components into a single, cohesive unit, we deliver a robust solution that guarantees quality and boosts your output. This production line, designed and commissioned entirely by Grand, has been rigorously tested to achieve a consistent and reliable speed of 30 finished small boxes of candy per minute, making it the ideal investment for growing businesses and established manufacturers alike.

Develop Your Business with Grand

Get a Quote Today!

An In-Depth Look at Grand's Integrated Candy Packaging Machinery

Our production line is not just a collection of machines; it's a synchronized system where each component is optimized to work in harmony. Let's explore the journey your product takes through our state-of-the-art line.

1. Gentle Elevation & Precision Weighing (Hoist & Multi-head Scale)

The process begins with precise weighing.

- Z-type bucket elevator: Bulk candies are first loaded into a food-grade hopper. Then, a Z-type bucket elevator gently conveys the product upward to the weighing machine. This design is crucial for delicate candies, minimizing breakage and preserving their quality and appearance.

- High-precision multi-head weigher: At the top of the structure lies the "brains" of the weighing operation: the multi-head weigher. This advanced candy packaging machine utilizes a computer-controlled combination weighing system. Multiple weighing heads simultaneously calculate dozens of weight combinations to select the one that is closest to the target weight without falling below it.

2. The Heart of the Line: Automated Cartoning & Sealing (Boxing & Glue Machine)

After weighing, the precisely measured quantity of candy is automatically packed into the box. This is accomplished by our high-speed, fully automated packaging machine (the core equipment of the production line).

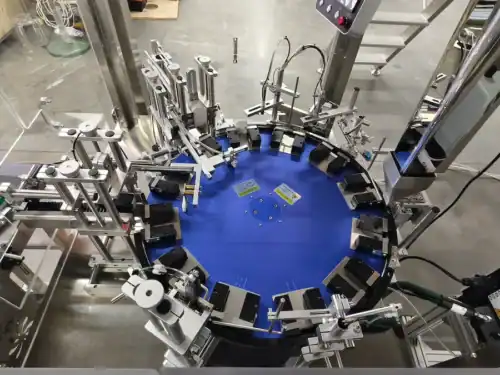

- DJ-50D Top-Opening Cartoning Machine: The machine takes a flat, folded cardboard box, shapes it, and places it on a rotating indexing table. As the opened box rotates into position, the multi-head scale above releases the weighed candy, which cleanly and neatly drops into the box.

- Precision hot melt adhesive system: A perfect seal is crucial for product safety and shelf appeal. To ensure this, our production line incorporates the world-class Robatech Concept hot melt adhesive machine. This Swiss-made system is renowned for its reliability and precision.

3. Seamless Transition: The Conveyor System (Conveyor Belt)

The entire production process is linked by a series of robust, food-grade conveyor belts.

- Space-saving: The U-shaped design allows the entire production line to be arranged in a smaller footprint, saving valuable factory floor space.

- Smooth production: The U-shaped conveyor belt ensures continuous and smooth transport of candy packaging boxes from the packaging machine to the labeling station, preventing production bottlenecks.

- Easy operation: This layout brings the start and end points of the packaging process closer together, allowing a single operator to easily monitor the entire production line and manage the finished products.

4. The Finishing Touch: Automatic Labeling (Labeling Machine)

The final step in preparing your product for retail is labeling. The sealed boxes travel along the conveyor to a high-speed automatic labeling machine. Double-Sided Labeling Machine can be configured to apply various types of labels with exceptional precision, including:

Brand and product labels

Nutritional information and ingredient lists

Barcodes for inventory management

Promotional stickers or tamper-evident seals

The precise application ensures that every label is perfectly placed without wrinkles or skews, enhancing your product's shelf presence and brand integrity.