What Size Pills Can a Pill Press Make? Understanding Pill Size, Tooling & the GZPK-26

Packaging mechanical structure similar to the 2025 Nobel Prize in Medicine!

What are the common packaging of cold medicines?

Introduction

With the recent change of seasons in southern China, I've started experiencing a sore throat. In China, we often seek medication when we're sick, and common medications are easily available at pharmacies. So what are some common medications? And what packaging do they use?

As a manufacturer of pharmaceutical packaging machinery, how does Grandpack use its large-scale machinery to package and mass-produce medications? I'll briefly explain. Although the mechanical principles are simple, these machines are truly accessible to the public and are an excellent tool for pharmaceutical manufacturers.

Six Major Pharmaceutical Packaging Methods:

Pharmaceutical packaging may seem simple, but there's a lot of complexity behind it! Each packaging method has its own unique function and purpose, protecting the medication and enhancing its stability, ensuring safe use.

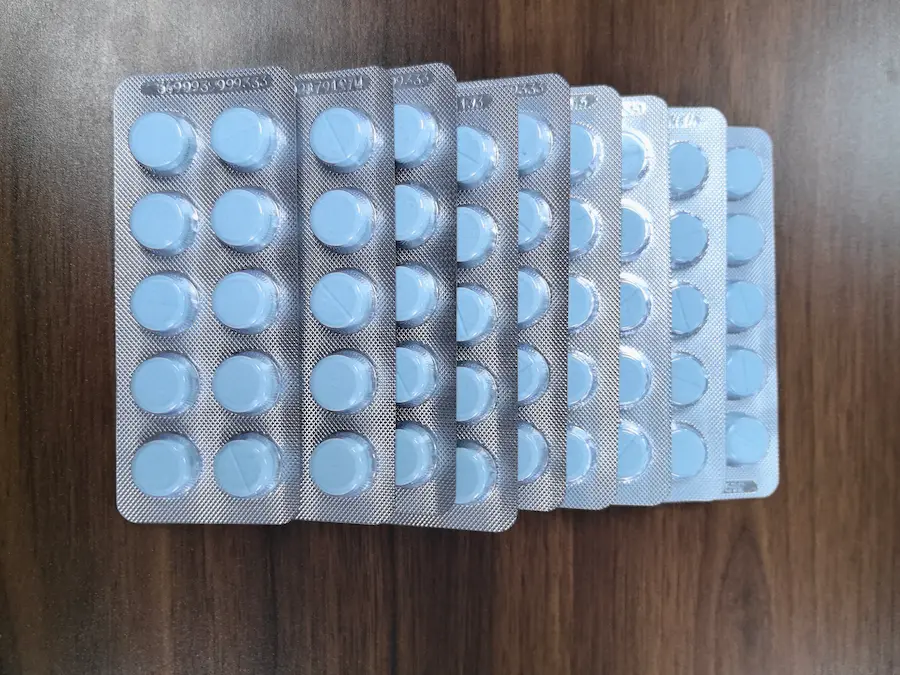

1. Blister packaging: Many people may not pay much attention to it, but it's actually a very common packaging method. Typically made of PVC or PVDC, it effectively blocks moisture and UV rays, protecting medications from environmental influences. It's absolutely essential for tablets and capsules! This is the strength of Grandpack's blister packaging machinery: its meticulous attention to detail and high-speed production capacity are industry-leading.

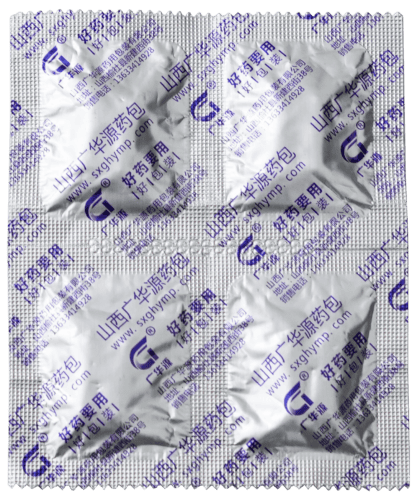

2. Stick packaging is generally used for large-dose or highly hygroscopic medications. It seals the medication with two layers of pharmaceutical film, providing both moisture and UV protection. This type of packaging is particularly suitable for medications that require heat and cold resistance, effectively extending their shelf life.

3. Bag packaging is very common, especially for medications such as tablets, granules, and powders. It uses lightweight materials such as polyethylene and aluminum foil to effectively block moisture and protect the medication's quality from environmental influences. The lightweight packaging is convenient for storage and use, making it very practical.

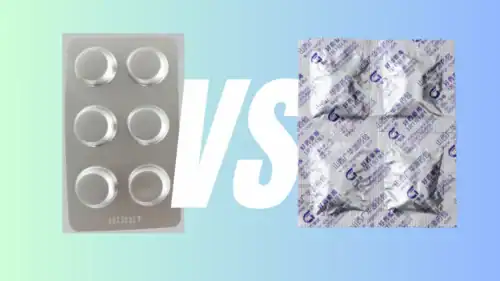

4. Double aluminum packaging uses two layers of aluminum foil to seal the medication, effectively preventing the intrusion of oxygen and moisture. It is ideal for medications that need to be protected from light and moisture. For example, tablets and pills require this exceptionally strong seal to protect the medication from external factors.

5. The packaging of aqueous injections has evolved to plastic ampoules, which are safer than traditional glass ampoules, have a lower breakage rate, and are easier to transport and store. This higher production efficiency not only solves the problem of fragile glass ampoules but also reduces operational complexity, making it an ideal choice for injectable medications. Grandpack also offers corresponding GGS machinery to help pharmaceutical companies increase their production capacity for plastic ampoules. This includes packaging lines for oral liquids and machinery for disposable cosmetics.

6. Flexible plastic bottle packaging is particularly suitable for liquid medications such as infusions and syrups. Materials such as polycarbonate (PC) and polyethylene (PE) provide a strong seal, protecting the medication from external contaminants. Furthermore, this packaging design is user-friendly and easy to handle.

7.Medicine bottle packaging, this method is mostly common in cans of tablets or soft capsules.

Machine Packaging Techniques from China

China has rapidly evolved from traditional Chinese medicine prescriptions to the integration of Western medicine, and pharmaceutical packaging machinery has significantly contributed to this. For example, the common blister pack is divided into aluminum-plastic blister and aluminum-aluminum blister packs. Below are images of medications produced by Grandpack machinery.

Aluminum-aluminum blister packaging also has a similar packaging method: soft double aluminum packaging. Interested parties can find the answer in the article "Strip Pack vs. Alu-Alu Blister — Which is Right for Your Product?".

So what are the advantages of Grand brand blister machines?

1. Easiest mold change! 2. Reliable design! 3. High-quality customization!

After the pharmaceutical manufacturer provides the corresponding production capacity requirements and the product to be packaged, Grand's sales manager will quickly provide the pharmaceutical production layout and inquire about further pharmaceutical packaging functions, such as cursor alignment, visual inspection, and rejection.

Our blister machines make mold changes easy and fast; even customers who have never used this machine can quickly master it in minutes.

Reliable design: For tablet packaging, our hopper is designed with a screening device to screen out excess powder effectively.

Regarding customization, we offer extended lengths and widths for the production and packaging of specialized medications. We also provide efficient after-sales service and comprehensive guidance.

Regarding customization, we offer extended lengths and widths for the production and packaging of specialized medications. We also provide efficient after-sales service and comprehensive guidance.

After all this talk, my cold medicine still isn't finished? Yes, after blister packaging, a cartoning machine is responsible for uniformly boxing the medications. Then, inspection, packaging, and palletizing complete the process. Grand can handle the entire packaging process. Our machinery can form a comprehensive production line, encompassing tablet preparation, tablet presses, capsule filling machines, blister packaging, sachet packaging, and soft double aluminum packaging machines, as well as cartoning, palletizing, and other processes. Pharmaceutical manufacturers can choose us with confidence.

Finally, it's time to buy my cold medicine. I hope to receive complete packaging with clear printing for safe use. If you need packaging, please contact us immediately by emailing sales@grandpackmachine.com, using the form on the right, or by using our WhatsApp number. We are always happy to provide detailed machine guidance.