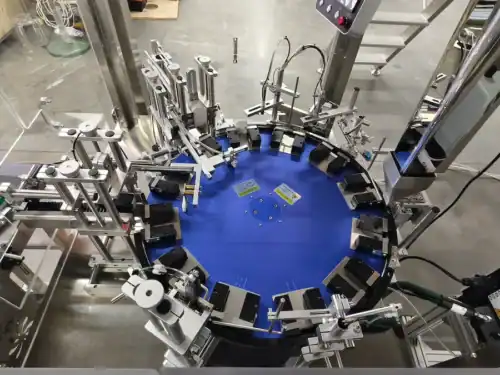

Automatic Tablet Tube Filling Machine Customer Case Study

What Materials Are Used in Medical Blister Packaging? | Grandpack

Boost Efficiency & Cut Costs | Grand Automatic Cartoning Machine

From Bottleneck to Breakthrough

In every production facility, packaging often becomes the silent bottleneck that limits growth. Even as upstream processes become more automated, many manufacturers still rely on manual or semi-automatic cartoning. The result? Rising labor costs, inconsistent quality, and limited scalability.

Common challenges include:

High labor costs, especially in Europe and the Americas

Slower cycle times compared to other automated stages

Packaging inconsistencies that affect product presentation

Frequent human errors leading to downtime or waste

For companies looking to stay competitive, these are not small inefficiencies—they are profit leaks. Fortunately, automation technology has matured to the point where upgrading is no longer complex or risky.

That’s where Grand Machinery’s automatic cartoning machine comes in—a smart, high-ROI investment designed to boost efficiency, cut operating costs, and deliver long-term reliability.

What Is an Automatic Cartoning Machine and How Does It Work?

An automatic cartoning machine is an intelligent packaging system capable of performing a series of automated operations—carton suction, forming, product insertion, flap folding, gluing, and sealing—all in one streamlined process.

Learn more : A Deep Dive into the Modern Cartoning Machine

In simple terms, it replaces multiple manual packaging steps with a single, high-speed and consistent workflow.

In the demonstration video, for example, Grand’s high-speed cartoning machine seamlessly packs soft tubes into folding cartons—precisely, efficiently, and safely.

This technology doesn’t just increase speed—it ensures accuracy, packaging consistency, and product integrity, which are key to any modern automatic packaging line.

Inside the Process: Step-by-Step Precision

High-Precision Carton Feeding (00:14)

Flat cartons are automatically picked one by one from the magazine. Grand’s servo-driven feeder ensures stable, smooth, and continuous operation, even during long runs.

Accurate Opening and Forming (00:18)

Using vacuum suction or robotic arms, each carton is perfectly opened and placed in the conveyor chain. This guarantees accurate forming, which is critical for high-volume pharmaceutical cartoner machines.

Synchronized Product Loading (00:24)

Products—such as tubes, blisters, or bottles—are grouped and timed to match the carton flow. The synchronization minimizes product jams and optimizes production rhythm.

Smooth Product Insertion (00:30)

A precise pushing system gently inserts products into cartons without vibration or damage—an essential feature for cosmetic and food-grade packaging lines.

Automatic Folding and Hot Melt Sealing (00:37)

Finally, the flaps are folded and sealed. The integrated hot melt glue cartoning machine system (00:39) ensures a strong, clean, and visually appealing finish. The result: consistent, retail-ready packaging.

Why Global Manufacturers Trust Grand Automatic Cartoning Machines[1]

1. Exceptional ROI and Productivity

The Grand automatic cartoning machine operates 24/7 with minimal supervision, achieving packaging speeds that far exceed manual capacity.

Customers typically experience a return on investment (ROI) within the first year, thanks to reduced labor costs and improved efficiency.

2. Lower Labor Costs, Fewer Human Errors

One cartoning system can replace multiple packaging operators. This not only saves costs but also eliminates errors caused by fatigue or inconsistency—boosting overall productivity and reliability.

3. Consistent, Premium Packaging Quality

Manual packaging often results in uneven folds, glue overflow, or alignment issues. Grand’s CE and GMP-certified packaging machine ensures each carton is identical, clean, and professional—enhancing your brand’s reputation.

4. Built for Long-Term Reliability

Every Grand cartoner is built with high-quality materials, precision mechanics, and globally sourced components.

They are engineered for reliability, delivering consistent uptime with low maintenance. Many global clients run Grand machines continuously for years with minimal downtime.

5. Smarter Material Utilization

Through intelligent control and servo precision, the machine reduces waste of cartons, glue, and product. The result is a more sustainable, cost-efficient packaging automation process.

6. Flexible and Scalable Design

Grand’s cartoning machine for tubes and bottles is easily adjustable to handle multiple product sizes. Quick mold changes, adjustable parameters, and optional modules (for leaflet insertion or printing) make it ideal for multi-SKU production lines.

Hot melt glue sealing system on Grand cartoner

7. Proven Export Experience & Global After-Sales Support

Grand Machinery serves clients across Europe, Asia, South America, and the Middle East, supplying reliable packaging equipment that meets international standards.

Our service team provides:

On-site installation and operator training

Remote troubleshooting and maintenance

Fast spare parts delivery

When you choose Grand, you’re not just buying a machine—you’re partnering with an experienced cartoning machine manufacturer in China that understands global manufacturing standards.

Where Grand Cartoners Deliver the Best Results

Grand’s automatic cartoning machines are suitable for a wide range of industries:

Pharmaceuticals: blister packs, ointment tubes, oral liquids, vials

Cosmetics: skincare tubes, perfumes, soap bars

Food & Beverage: instant coffee, biscuits, chocolates, ice cream sticks

Daily Goods & Household Items: toothpaste, stationery, hardware

Across these industries, Grand helps customers achieve consistent packaging quality, regulatory compliance, and production flexibility—key advantages in competitive markets.

The Grand Advantage: Engineering Meets Experience

Behind every Grand automatic cartoning machine lies a combination of mechanical expertise, real-world experience, and global customer feedback.

Our R&D team continuously refines motion control systems, feeding mechanisms, and safety protocols to enhance performance and reliability.

Whether you operate a pharmaceutical cleanroom in Germany or a food plant in Southeast Asia, Grand machines are built to perform under demanding conditions—delivering long-term reliability and high ROI.

Moreover, Grand is known for its customer-first philosophy. We don’t just sell equipment—we deliver packaging automation solutions that grow with your business.

Invest in a Proven Cartoning Solution with Fast ROI

In today’s manufacturing world, automation is not optional—it’s essential for staying competitive.

The Grand automatic cartoning machine gives you:

A faster, more efficient, and safer packaging process

Consistent product quality and strong brand presentation

Reduced labor costs and material waste

Reliable after-sales support and international service coverage

Upgrade your production line today and see why manufacturers worldwide trust Grand Machinery to power their packaging automation success.

Ready to Automate Your Packaging Line?

Your production deserves the precision and efficiency of Grand.

📧 Email: sales@grandpackmachine.com

Let’s build a smarter, faster, and more profitable packaging line—together with Grand.

References:

[1] Your Guide to the Top 11 Cartoning Machine Manufacturers