Boost Efficiency & Cut Costs | Grand Automatic Cartoning Machine

What Is a Shrink Wrap Machine?

What Materials Are Used in Medical Blister Packaging? | Grandpack

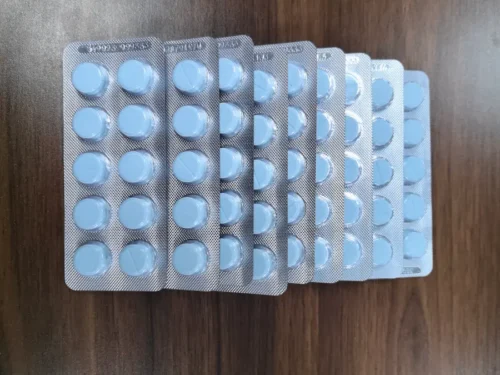

Blister packs have become a cornerstone of medical blister packaging, offering safe, reliable, and cost-effective protection for tablets, capsules, and other solid dose medicines. They combine transparency, hygiene, and portability — key factors in modern pharmaceutical packaging.

This article explains what a blister pack is, explores the materials used, compares different medicine packaging types, and shows how Grandpack’s DPP360 Blister Packaging Machine provides exceptional flexibility and eco-friendly performance for pharmaceutical manufacturers.

What Is a Blister Pack?

A blister pack is a pre-formed plastic packaging system containing individual cavities (or “blisters”) that securely hold tablets or capsules. Each cavity is sealed with a backing layer — usually aluminium foil or composite film — to protect the medicine from moisture, oxygen, and contamination.

This design offers clear benefits:

Protection – prevents moisture and light damage.

Safety – tamper-evident and hygienic.

Patient compliance – allows easy dose tracking.

In short, blister packs are one of the most practical medicine blister packs used by pharmaceutical manufacturers and hospitals worldwide.

Common Materials Used in Blister Packaging

The core of any plastic blister lies in the materials chosen for its forming and lidding layers. Different combinations offer varying degrees of protection, cost, and sustainability.

1. PVC (Polyvinyl Chloride)

PVC is the most commonly used thermoforming film in tablet blister packs. It is inexpensive, clear, and easy to shape. However, it offers only moderate protection against moisture and oxygen.

2. PVDC (Polyvinylidene Chloride)

To enhance barrier properties, PVC is often coated with PVDC. This improves protection but slightly increases cost and complexity. PVDC-coated PVC films are standard in high-grade capsule blister packs.

3. PET and COP Films

PET (Polyethylene Terephthalate) and COP (Cyclic Olefin Polymer) are modern alternatives that offer better clarity and recyclability. Many companies are adopting these films to support sustainable types of blister packaging.

4. PCTFE (Polychlorotrifluoroethylene)

Used in premium packaging, PCTFE provides superior moisture and oxygen resistance — ideal for highly sensitive medicines.

5. Aluminium Foil and Cold-Form Foil

The lidding layer is typically aluminium foil, which seals the cavities and provides strong protection. For maximum barrier performance, cold-form Alu-Alu blisters use aluminium on both sides, eliminating light and moisture penetration. You can learn more about this method in our Ultimate Guide to Blister Packaging.

Blister Packs vs Other Medicine Packaging Types

Pharmaceutical companies use various medicine packaging types, including bottles, sachets, and pouches. However, blister packs offer several distinct advantages:

| Packaging Type | Key Features | Pros | Cons |

|---|---|---|---|

| Bottles | Bulk tablet storage | Reusable, cheap | Less protection per dose, harder to track usage |

| Sachets/Pouches | Flexible single-dose pack | Excellent moisture barrier | Not rigid, less visual appeal |

| Blister Packs | One cavity per dose | Maximum product safety, easy compliance, tamper-evident | Harder to recycle (traditional materials) |

Blister packs are especially valued for dose accuracy and patient adherence — two critical priorities in regulated pharmaceutical production.

For a detailed comparison of configurations, see our Types of Blister Packaging Explained.

Sustainability in Blister Packaging

Sustainability is now central to pharmaceutical packaging design. Traditional PVC/PVDC and aluminium combinations are difficult to recycle due to mixed materials. This has led to an industry shift towards more recyclable films such as PET or polypropylene (PP).

At Grandpack, we embrace sustainable innovation. Our engineers continuously test eco-friendly materials and machine configurations that reduce waste and energy use. This aligns with the company’s vision of practical, environmentally responsible design.

If you want to explore greener production lines, our post on Sustainable Pharma Packaging Solutions explains how energy-efficient blister systems can support long-term environmental goals.

The Grandpack DPP360 Blister Packaging Machine

For manufacturers seeking a robust and adaptable blister solution, the Grandpack DPP360 is an outstanding choice.

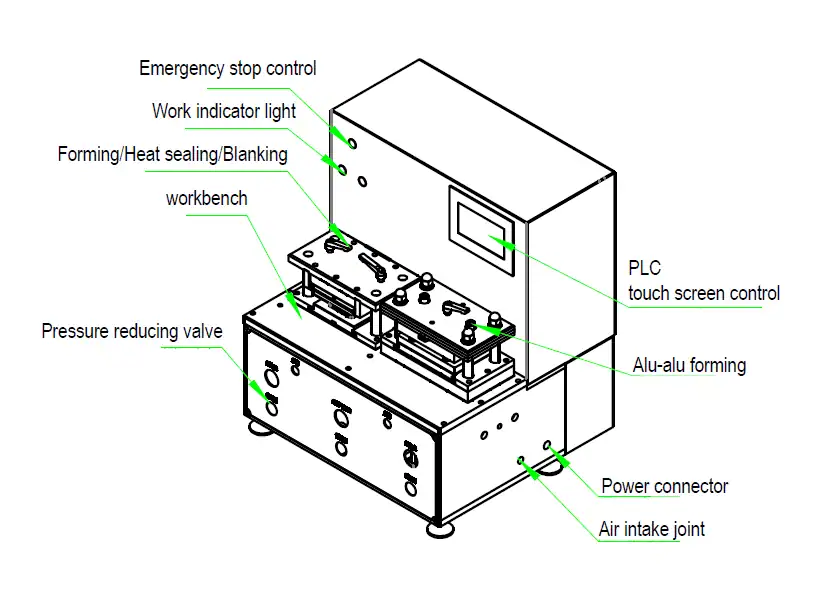

This high-speed machine supports both Alu-PVC and Alu-Alu packaging formats. It features precision forming, automatic temperature control, and intelligent sensors for consistent sealing.

Key advantages:

Quick mould change – switch between tablet, capsule, or liquid formats in under 30 seconds.

Flexible dosing – optional ceramic pump allows accurate liquid filling.

Low waste design – efficient forming reduces material loss.

Reliability – all-aluminium structure ensures durability and stability.

The DPP360 perfectly represents Grandpack’s “smart, sustainable, and practical” product philosophy — maximising productivity while reducing operational impact.

For specifications and configurations, visit the Grandpack DPP360 Blister Packaging Machine page.

Why Choose Blister Packaging for Your Pharma Products?

Blister packaging provides unmatched protection, visibility, and patient convenience. When combined with modern, energy-efficient equipment, it becomes a cornerstone of safe, sustainable pharmaceutical manufacturing.

Grandpack’s focus on medical blister packaging helps clients achieve:

Consistent product quality

Faster production cycles

Compliance with GMP standards

Lower waste and energy costs