What Is a Shrink Wrap Machine?

What Is a Ribbon Blade Mixer? A Complete Guide

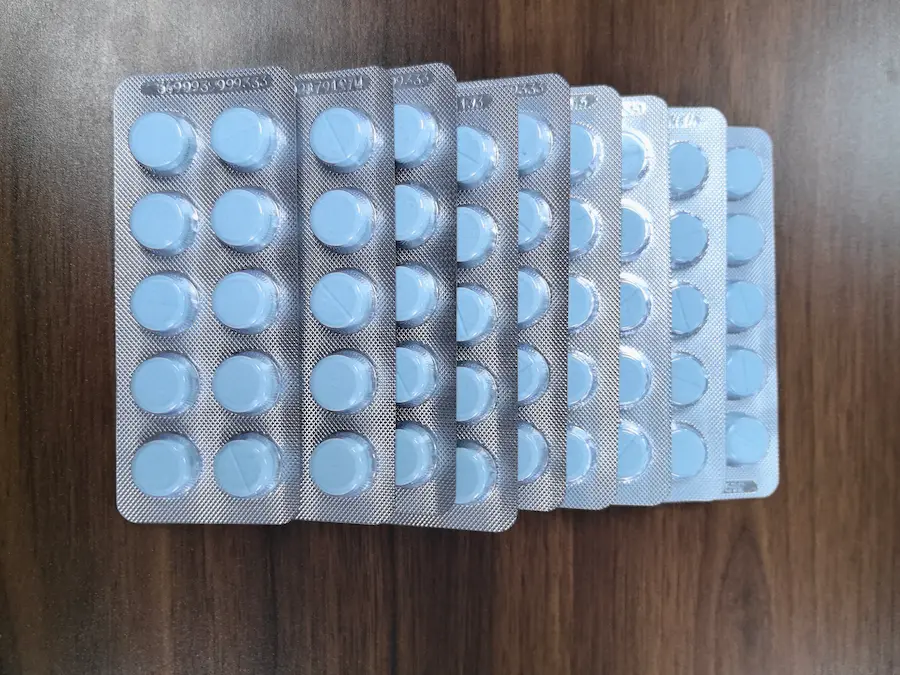

Why Are Pills in Blister Packs? A Guide to Shelf Life & Safety

Introduction

Have you ever found a stray pill in the bottom of a bag or a drawer? Your first thought might be, "Is this still good?" It’s a common question, and it leads to a more important one: why are so many medications, from tablets to capsules, sealed in those individual plastic and foil "bubbles"?

This packaging, known as a blister pack, is far more than just a convenient way to sell medicine. It's a high-tech, single-dose delivery system designed for one primary purpose: protection.

Blister packaging is engineered using advanced thermoforming and cold-forming materials, helping to maintain medication stability, prevent degradation, and ensure long-term shelf life. This article will explore the critical role blister packs play in medication stability, answer your pressing questions about shelf life, and introduce the sophisticated technology required to create these essential packages.

What's the Point of a Blister Pack?

A pills blister pack is a form of unit-dose packaging that seals each pill in its own separate cavity. This cavity, or "blister," is typically made from thermoformed plastic, while the backing is a push-through or peelable aluminum foil or composite laminate.

The reasons for this design include:

1. Environmental Protection: A blister pack creates a sealed micro-environment for each dose, protecting it from:

- Moisture & Humidity: Many tablets are hygroscopic and will absorb moisture, causing physical or chemical degradation.

- Oxygen Exposure: Exposure to air causes oxidation, reducing potency.

- Light: Photodegradable compounds require light-resistant blister materials such as colored PVC or aluminum foil.

2. Dosage Accuracy and Compliance: A tablet blister pack assists patients in tracking daily doses, improving medication adherence.

3. Safety and Integrity:

- Tamper-Evident: Physical barriers make tampering visible.

- Child-Resistant: Modern designs follow child-resistance standards.

- Contamination-Proof: Each pill remains sealed and untouched.

Answering Your Key Questions: Pill Shelf Life

The protection provided by a blister pack directly influences the shelf life of the medication.

"How long does a pill last in a blister pack?"

Pharmaceutical companies conduct extensive stability studies to determine how long a pill remains stable inside its sealed packaging.

Answer: A pill in an unopened blister pack remains stable until the expiration date printed by the manufacturer.

"How long do tablets last out of a blister pack?"

Answer: Once removed, the pill is exposed to humidity, oxygen, and light. Its degradation begins immediately.

Pharmacists advise consuming pills immediately after removing them from the blister. If placed into pill organizers, store them in a dry, cool, dark place, and only prepare a small number of days in advance.

"Can you remove pills from a blister pack?"

You can, but should only do so before taking the dose. Removing pills compromises their stability protection.

"Do pills go bad if not in a bottle?"

- Bottles: Provide multi-dose protection with desiccants but expose all pills during each opening.

- Blister Packs: Provide superior individual-dose barrier protection and extend stability in sensitive pharmaceuticals.

Learn more about blister pack types here: Types of Blister Packaging

The Technology Behind the Protection: Creating the Perfect Blister

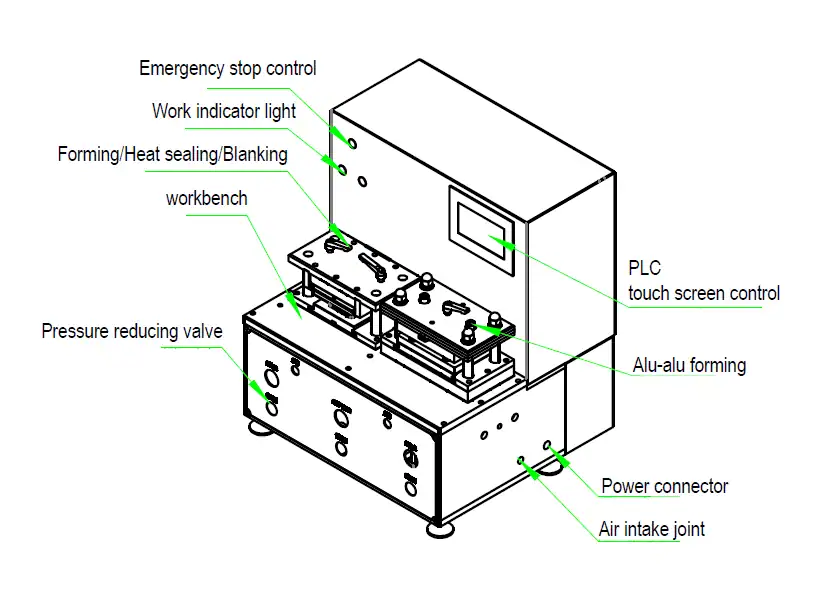

Creating high-integrity blister packs requires advanced machinery capable of forming precise cavities and sealing them flawlessly. At grandpackmachine, our self-developed DPP-260 Flat-Type Automatic Blister Packaging Machine is engineered for pharmaceutical, food, and nutraceutical applications.

See blister line working principle here: How Blister Lines Work

What Makes the DPP-260 an Ideal Packaging Solution?

1. Pinpoint Accuracy and Easy Operation

Forming, heat-sealing, batch printing, and cutting are all synchronised using a mandrel-fixed station structure. Operators can adjust all stations simultaneously by turning a single handle, ensuring accuracy and fast format changeover.

2. Versatility for Any Product Size

The DPP-260 uses a mechanical hand traction system with a double-pendulum mechanism, providing a stroke range of up to 180mm. This covers blister packaging formats for tablets, capsules, syringes, medical instruments, candy, and more.

3. Perfect, Uniform Blister Forming

The combination of positive-pressure air forming and precise mechanical punching ensures uniform blister forming, even for large or irregular products. It supports PVC/ALU, ALU/ALU, and special medical blister formats.

4. Reliable, Long-Lasting Design

The machine uses a high-grade bevel gear reducer and pin-positioned molds for precise alignment, longevity, and quick mold changes. Material waste is minimized due to optimized layout design.

5. Top-Tier Components

Equipped with Siemens PLC and touch screen, Panasonic servo motors, Schneider circuit protection, and Omron sensors, the DPP-260 delivers stability and long-term reliability.

Full machine specification available here: Blister Packaging Machine Specifications

Conclusion: Packaging Isn't Just a Box, It's a Science

As long as a blister remains intact, the medication inside remains protected until its expiration date. Once exposed to air, humidity, and light, the stability guarantee no longer applies.

The quality of a tablet blister pack or capsules blister pack begins with the quality of the machinery that forms and seals it. At grandpackmachine, we specialize in precision blister packaging technology built for pharmaceutical-grade protection.

If your pharmaceutical, nutraceutical, or food manufacturing operation requires a reliable, advanced, and versatile blister packaging solution, explore our full blister packaging line solutions.