Why Are Pills in Blister Packs? A Guide to Shelf Life & Safety

Top 10 Capsule Counter Export Suppliers in China

What Is a Ribbon Blade Mixer? A Complete Guide

Introduction

In any production line, from pharmaceuticals to food processing, consistency is king. Whether you're creating a protein powder, a pharmaceutical-grade excipient blend, or a chemical pigment, your final product is only as good as its most poorly mixed batch.

The challenge? Powders and granules don't like to be mixed. They segregate, clump, and settle. This is where the science of industrial mixing comes in, and at the heart of this world, you'll find an unassuming, reliable workhorse: the ribbon blade mixer.

You’ve probably heard the term, but what is a ribbon blade mixer? How does it work? Is it better than a paddle blender? And crucially, is it the right machine for your product?

This guide will demystify the ribbon mixer machine. We'll dive deep into its components, uses, and advantages, and even explore when you should consider a different type of mixer, like a V-blender or a 3D mixer.

What is a Ribbon Blade Mixer, Anyway?

At its simplest, a ribbon blade mixer (or ribbon blender) is a high-efficiency industrial mixer designed for blending dry, free-flowing solids. It can also be used to add minor liquid additions to a dry blend.

Visually, it's defined by two key features:

A U-Shaped Trough: This is the stationary horizontal vessel that holds the product.

A Horizontal Ribbon Agitator: This is the rotating "blade" element that does the actual mixing.

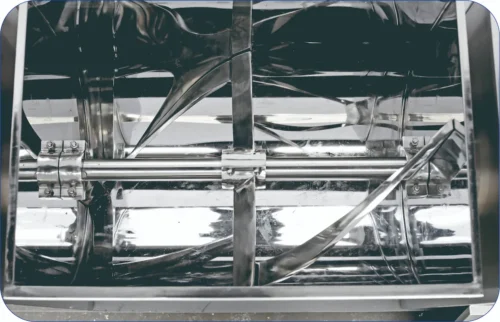

The agitator is the machine's true secret. It's not just one blade, but a precisely engineered set of inner and outer helical ribbons mounted on a central shaft. This design is what makes the ribbon blender so effective.

The Heart of the Machine: How Does a Ribbon Blender Work?

The mixing action of a ribbon blender is known as convective mixing. It's a fast, efficient, and surprisingly complex "throw-and-fold" action.

Here’s a step-by-step breakdown:

Material Loading: The U-trough is typically filled to 40-70% of its total capacity. This "working volume" is critical—underfilling or overfilling will destroy mixing efficiency.

Agitator Starts: The drive system (a motor and gearbox) begins to turn the central shaft.

The "Counter-Current" Flow: This is the magic.

The Outer Ribbon: This ribbon is angled and sized to continuously move material from the ends of the trough towards the center.

The Inner Ribbon: Simultaneously, the inner (and typically smaller) ribbon moves material from the center back out towards the ends.

This constant, opposing, counter-current flow ensures that every particle in the batch is in motion. It creates a "tossing" action that rapidly pulls material from one end to the other and back, all while the entire batch is being turned and folded.

This triple-mixing action (end-to-end, center-to-end, and radial) is incredibly thorough, often achieving a homogeneous blend in just 5 to 20 minutes, depending on the product's characteristics.

Key Components of a Ribbon Blender

When you're evaluating ribbon blenders, you're really evaluating the quality and design of these core components. Understanding them helps you ask the right questions.

The Mixing Trough (The "U-Vessel")

This is the main body. Key considerations are the material (e.g., 304 or 316L stainless steel for food/pharma), the quality of the welds (must be smooth, ground, and polished for cGMP compliance), and its heavy-duty construction to prevent flexing.

The Ribbon Agitator (The "Blade" Itself)

This is the heart. The "clearance"—the tiny gap between the outer ribbon and the trough wall—is critical. A gap that is too large (more than 3-6mm) will leave a "dead zone" of unmixed material at the bottom. A high-quality machine will have extremely tight tolerances.

The Drive System (Motor and Gearbox)

This is the muscle. The drive must be properly sized for your product's bulk density. A common mistake is buying a mixer sized for light powders (like flour) and then trying to mix a heavy-density product (like a mineral supplement). This will overload and burn out the motor. Always specify your product density.

The Lid and Safety Grate

A heavy, well-sealed lid is essential for dust containment and operator safety. Modern machines feature a safety interlock grate that immediately cuts power if the lid is opened during operation.

The Discharge Valve

How you get the product out is just as important as how you mix it. Common options include:

Slide Gate Valve: Good for fast-flowing powders.

Butterfly Valve: Better for powders that are slightly "sticky" or for finer control.

Bomb-Bay Door: A full-length bottom discharge for near-total cleanout, but it's more complex and expensive.

Common Ribbon Blender Uses Across Industries

One of the main advantages of a blender like this is its versatility. You will find ribbon mixer applications in dozens of industries:

Food & Beverage: Spice blends, cake mixes, flour, drink powders, seasonings, coffee blends.

Nutraceuticals: Protein powders, vitamin pre-mixes, supplement blends.

Pharmaceuticals: Blending Active Pharmaceutical Ingredients (APIs) with excipients (like lactose or starch).

Chemicals: Pigments, fertilizers, plastic resins and pellets, fire retardants.

Building Materials: Dry mortar mixes, cement, stucco, grout.

Cosmetics: Face powders, talc, mineral makeup blends.

Ribbon Mixer vs. Paddle Blender: What's the Difference?

This is the most common question we hear, as the two machines look very similar. A paddle blender also uses a U-trough and a horizontal agitator, but it uses "paddles" instead of ribbons.

The difference is in the mixing action:

Ribbon Blender: Creates an aggressive, end-to-end convective flow. It's ideal for blending materials of similar size, shape, and density. It is a workhorse for standard dry-powder blending.

Paddle Blender: The paddles create a "fluidized-bed" effect, lifting and "floating" the materials in a "strike zone." This action is much more gentle.

When to choose a Paddle Blender:

Friable Materials: If you are mixing delicate items that can't be broken (e.g., granola, tea leaves, some chemical flakes).

Liquid Additions: Paddles are often superior for incorporating liquids into a solid, as they "coat" the particles more effectively without creating "dough balls."

Different Densities: The fluidizing action of a paddle is better at keeping very heavy and very light particles from segregating.

| Feature | Ribbon Blender | Paddle Blender |

| Primary Action | Convective (End-to-End) | Fluidizing (Lift & Float) |

| Best For | Similar-sized powders, speed | Friable materials, liquid additions |

| Aggressiveness | High | Low (Gentle) |

| Mix Time | Fast | Very Fast |

The Big Decision: New vs. Used Ribbon Mixer

When budgets are tight, the allure of a used ribbon mixer is strong. However, this is an area where you must be extremely cautious, especially for food or pharma applications.

Risks of a "Used Ribbon Mixer":

Contamination: You have no idea what was in it last. A poorly cleaned mixer can harbor bacteria or chemical residues that can cross-contaminate your product.

Metal Fatigue: Mixing is a high-stress operation. Hidden cracks in welds or on the agitator can fail, sending metal fragments into your product.

Worn Tolerances: As mentioned, the clearance between the ribbon and trough is key. On a used machine, this gap is often worn down, leading to poor mixing and product left in the trough.

No Warranty or Support: When it breaks, you're on your own.

A new machine from a reputable manufacturer ensures cGMP compliance, is built for your product density, comes with a warranty, and guarantees a pristine, contamination-free mixing environment.

Sizing Matters: From Small Ribbon Mixer to Production-Scale

You'll see mixers advertised by their "total volume." But as we learned, you can't fill it to the top. The most important number is the working volume (typically 40-70% of total).

Small Ribbon Mixer (Lab-Scale): These are vital. Ranging from 5L to 50L, these are used for R&D, pilot batches, and testing new formulations before you risk hundreds of kilograms of raw material on the production floor.

Production-Scale Mixers: These can range from 100L to over 10,000L. The key is to match the mixer's working volume to your typical batch size. A mixer that is half-full or 90% full will not mix properly.

Beyond the Ribbon: When Do You Need a Different Mixer?

The ribbon blender is a fantastic, versatile workhorse, but it is not a unicorn. It can't solve every mixing problem. A good supplier won't just sell you a ribbon mixer; they'll ask about your product and, if necessary, guide you to a better technology.

Sometimes, your product demands a different approach.

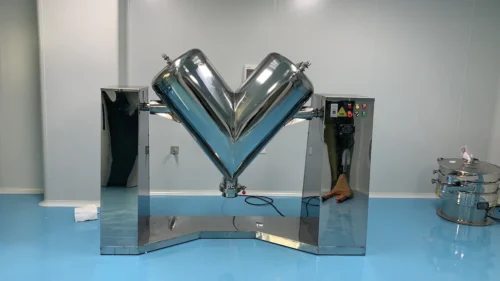

For Gentle, Homogeneous Blending: The V-Mixer (V-Blender)

Grandpackmachine V-type mixing mixer

You may have seen a machine like the V-shaped one in the image provided. This is a V-Mixer, a type of "tumble blender."

How it Works: The V-shaped vessel rotates, causing the material inside to split and rejoin with every turn. It's an extremely gentle, low-shear mixing action.

Best For: Friable granules, heat-sensitive powders, and pharmaceutical blends where particle breakage is unacceptable.

The Grandpackmachine Advantage: Manufacturers like Grandpackmachine offer a range of V-mixers for pharmaceutical and nutraceutical applications where product integrity is the absolute top priority. It's perfect for final blends right before tableting or encapsulation.

For Complex, Multi-Directional Mixing: The 3D (Three-Dimensional) Mixer

How it Works: This is the next level of tumble blending. The mixing vessel (often a drum) rotates on two separate axes at the same time, creating a complex, multi-directional flow that eliminates all "dead spots."

Best For: High-value, difficult-to-mix powders of vastly different densities or proportions (e.g., 0.1% of an active ingredient in 99.9% of a carrier).

The Grandpackmachine Advantage: For the most demanding R&D or high-potency blends, a 3D mixer, also available through Grandpackmachine, provides unparalleled homogeneity in a short time.

Conclusion: Is a Ribbon Blade Mixer Right for You?

The ribbon blade mixer has earned its reputation as the industry's go-to blender for a reason. It is fast, reliable, cost-effective, and highly efficient for a vast range of dry-blending applications.

If your process involves:

Blending dry powders of similar size and density.

A need for fast, repeatable batch mixing.

Applications in the food, chemical, or nutraceutical industries.

...then a ribbon blender is very likely the right choice for you.

Choosing a mixer is a critical process decision that impacts your product quality, batch time, and operational costs. Don't just buy a machine; invest in a solution.

We recommend talking to an expert who understands the full range of mixing technologies—from ribbon and paddle blenders to V-mixers and 3D units. A partner like Grandpackmachine can analyze your product, process, and goals to ensure you get the perfect mixing workhorse for your production line.