Are Pill Capsules Bad for You? Capsules vs. Powder vs. Liquid Absorption Guide

When is Soft Double Aluminum Packaging the Right Choice for Medicine Packaging?

High Shear Mixer Granulator HLSG-10: Precision Wet Granulation

Category: Pharmaceutical Machinery | Reading Time: 9 mins

In the complex world of solid dosage manufacturing, the quality of your final tablet or capsule is entirely dependent on the quality of your granules. While there are various methods to process powder—such as dry granulation or direct compression—High Shear Wet Granulation has emerged as the dominant technology for high-quality pharmaceutical production.

But not all granulators are created equal. For production managers and procurement officers, the challenge lies in finding a machine that balances efficiency with precision control.

Today, we are taking a deep dive into the Grandpack HLSG-10 Rapid Mixer Granulator (RMG). We will analyze why the "one-pot" processing method is superior and how the specific engineering of the HLSG-10 solves common production headaches regarding binder distribution and automation.

The Shift to Wet Granulation: Efficiency meets Quality

Wet granulation + fluidized bed drying line

Why has the industry largely standardized on High Shear Mixing? The answer lies in the physics of particle bonding.

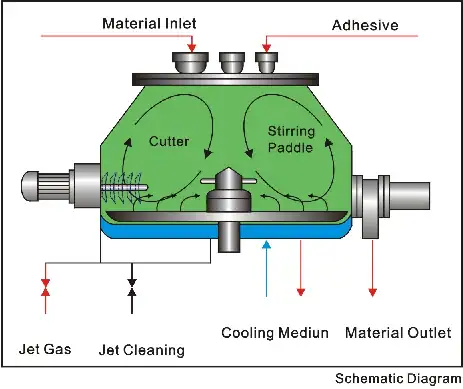

Traditional low-shear granulation often results in loose granules and inconsistent density. In contrast, a High Shear Mixer Granulator (often called an RMG) utilizes a high-speed impeller and a chopper blade to impart significant mechanical energy into the powder mix.

The Grandpack HLSG-10 is designed to achieve three critical steps in a single operation:

Dry Mixing: Homogenizing the powder.

Binder Addition: Adding liquid to form wet mass.

Granulation: Breaking down the mass into uniform granules.

By consolidating these steps, the HLSG-10 delivers "high production efficiency and excellent granulation quality". This "one-pot" approach minimizes material transfer, reduces cross-contamination risks, and significantly cuts down processing time.

Inside the HLSG-10: Engineered for Precision

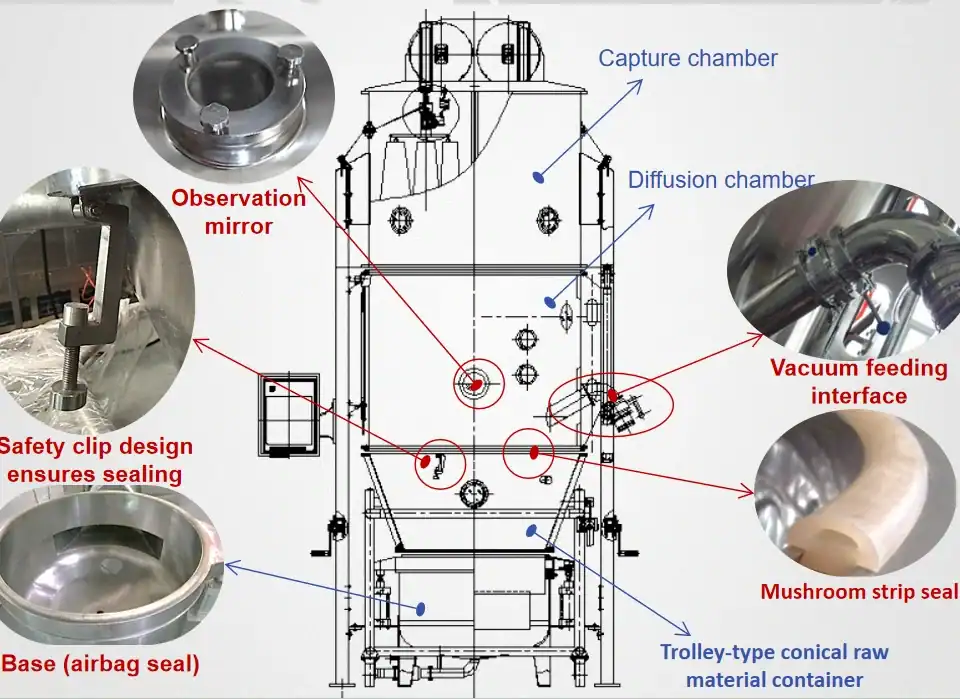

When evaluating a granulator, you must look beyond the exterior stainless steel and examine the working principles. The HLSG-10 utilizes a top conical bowl design.

stirring paddle

Why the Conical Bowl Matters

In older cylindrical designs, materials could get trapped in corners, leading to "dead spots" where powder remains unmixed. The conical shape ensures a rolling movement of the material. As the impeller rotates, the powder is lifted and tumbled, ensuring 100% of the batch is subjected to the same mixing forces.

The Dual-Force Mechanism

Granulation knife

The HLSG-10 operates using two independent motors:

The Impeller: Running between 50 - 500 rpm (controlled via Variable Frequency Drive), it creates the vortex necessary for mixing.

The Chopper: Running at high speeds of 60 - 3000 rpm.

Once the binder is added, the high-shear chopper "continuously cuts and refines the granules". This ability to adjust rotational speeds allows you to customize the granule density and size to meet specific requirements. Whether you are producing porous granules for fast dissolution or dense granules for sustained release, the VFDs give you total control.

Innovation in Binder Distribution

One of the most common failures in wet granulation is "local over-wetting." This happens when the binder liquid hits the powder in a concentrated stream, creating hard lumps that the chopper cannot break down.

Grandpack has addressed this with a pioneered binder introducing unit.

Instead of dumping the binder, it is added through a feeder and "distributed to the materials to form granules rapidly". The result?

Lower Binder Consumption: You save on raw material costs.

Shorter Granulation Time: The wet mass reaches the endpoint faster.

Uniformity: The granules are uniform in size and firmness, which is critical for the subsequent tablet compression stage.

Build Quality: A Look at the Component List

For a buyer, the reliability of a machine is often determined by the brands inside the electrical cabinet. Proprietary, unknown electronic components are a maintenance nightmare.

The HLSG-10 is built with a "Global Standard" philosophy, utilizing top-tier international components that ensure stability and easy procurement of spare parts.

Key Component Breakdown:

The Brain: The machine is controlled by a Siemens PLC (Model ISR20-OAAO) paired with a Siemens SMART 700 HMI touchscreen. This provides a stable, user-friendly interface for process monitoring.

Motor Control: Frequency converters (VFDs) for the 2.2kW mixing motor and 0.75kW chopper motor are supplied by Delta. Delta drives are renowned for their precision in speed regulation.

Electrical Safety: Critical safety components like Circuit Breakers and Miniature Relays are sourced from Schneider Electric.

Pneumatics: The solenoid valves controlling the air systems are from AirTAC, ensuring reliable pneumatic operation.

This configuration drives the machine through a combination of "photoelectric, electric, and pneumatic systems", ensuring that if one sensor detects an anomaly, the system responds instantly.

Operational Safety and Ease of Use

In modern GMP (Good Manufacturing Practice) environments, operator safety and cleanability are non-negotiable.

Automation

Gone are the days of manual stopwatch timing. The HLSG-10 allows you to set operation time and speed parameters on the HMI. After startup, the impeller begins mixing at the exact set speed automatically. Once the cycle is complete, the discharge port opens to allow "automatic discharging of the granules," reducing manual handling and operator fatigue.

Safety Systems

Grandpack includes an automatic protection system. This includes features like the Emergency Stop Switch (Delta) and Lockable Switches (Schneider) to prevent accidental startups during maintenance or cleaning. The machine is also equipped with a temperature control system for the jacket, preventing heat-sensitive APIs from degrading during the high-energy mixing process.

Versatility (Lab to Pilot)

The HLSG-10 is specifically sized for R&D labs or pilot production.

Total Hopper Volume: 10 Liters.

Working Volume: 2 - 8 Liters (depending on material).

Batch Loading: Approx. 1 - 4 kg per batch.

This makes it the perfect bridge machine to test formulations before moving them to large-scale production lines.

Conclusion: The Smart Investment for Granulation

Choosing the right High Shear Mixer Granulator is about mitigating risk. You need a machine that minimizes material waste, ensures batch-to-batch consistency, and won't break down when you need it most.

With its Siemens-powered automation, innovative binder distribution system, and robust stainless steel construction, the Grandpack HLSG-10 offers a premium granulation solution without the premium complexity. It is capable of processing materials across pharmaceuticals, food, and chemicals, making it a versatile asset for any production facility.

Ready to upgrade your granulation process? Contact the Grandpack technical team today to discuss how the HLSG-10 can fit into your current production line.