When is Soft Double Aluminum Packaging the Right Choice for Medicine Packaging?

How to Melt Gummies: A Guide to Rework & Production | Grandpack Machine

Types of Soft Capsules & Production Line

Category: Pharmaceutical Manufacturing | Reading Time: 12 mins

In the vast landscape of pharmaceutical and nutraceutical dosage forms, soft capsules (often called softgels) reign supreme in consumer preference. They are easy to swallow, mask unpleasant tastes, and offer superior bioavailability for oil-based formulations.

But for manufacturers, entering the Soft Capsule Production market involves navigating a complex matrix of geometry and engineering. It is not just about buying a machine; it is about understanding how the shape of the capsule dictates the speed of your production line and orchestrating a symphony of auxiliary equipment to ensure quality.

In this deep dive, we will explore the different Types of soft capsules, analyze the relationship between soft capsule size and machine output using the Grandpack RJWJ-115 as a case study, and review the safety standards required for modern production.

Part 1: The Geometry of Dosage – Exploring Types of Soft Capsules

When we talk about softgels, size and shape are not merely aesthetic choices; they determine the volume of the active ingredient (fill weight) and the patient's experience.

Softgel sizes are traditionally measured in "minims," an apothecary unit of volume, though modern specifications also include cubic centimeters (cc).

1. Round Shapes

As the name suggests, these are spherical. They are often used for oil-based vitamins like Vitamin D or E.

- The Range: Starts from tiny "1 Round" (0.046 - 0.062 cc) up to massive "90 Round" sizes.

- Production Note: Because they are symmetrical, they often allow for high-density packing on the die roll, leading to efficient production numbers.

2. Oval and Oblong Shapes

These are the most common shapes for multivitamins and fish oil supplements.

- Oval: Elliptical but relatively stout. A "4 Oval" holds approximately 0.191 - 0.246 cc.

- Oblong: Elongated with parallel sides. This shape is preferred for larger dosages (like 1000mg fish oil) because the slender profile makes them easier to swallow than a round capsule of the same volume.

- Size Impact: As seen in standard charts, a "20 Oblong" is significantly larger (0.986 - 1.232 cc) than a "4 Oblong".

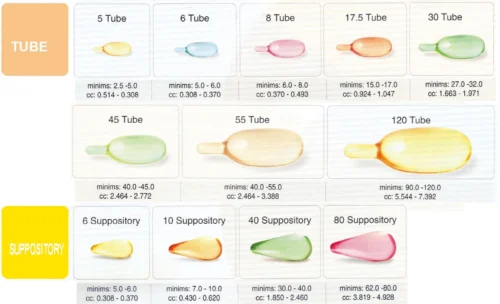

3. Tube and Suppository Shapes

These are specialized types of soft capsules.

- Tube: Often used for single-dose topical applications (twist-off tails) or cosmetics.

- Suppository: Designed specifically for rectal or vaginal insertion, featuring a tapered end for ease of use.

- Volume: These can get quite large. For example, a "120 Tube" can hold up to 7.392 cc of liquid.

Part 2: The Capacity Equation – How Size Impacts Speed

One of the most critical concepts for a buyer to understand is that Soft capsule unit production speed is not fixed. It is dynamic and inversely proportional to the size of the capsule.

To illustrate this, let’s look at the technical data for the RJWJ-115 Soft Gelatin Encapsulation Machine. This machine uses a pair of die rollers (Φ72×110mm) to form the capsules11. The amount of "real estate" on these rollers is limited.

The Speed vs. Size Trade-off:

- Small Capsules (High Output): When producing a small Oval 4# capsule, the die roll can fit many cavities. Consequently, the RJWJ-115 can produce around 26,460 pieces per hour22.

- Medium Capsules: If you switch to an Oval 8#, the capacity drops to roughly 15,300 pieces per hour.

- Large Capsules (Lower Output): For a large Oval 20#, the output reduces further to 9,360 pieces per hour.

- Shape Variance: Even with similar sizes, shape matters. An Oblong 20# runs at about 8,100 pieces per hour, slightly slower than the Oval 20# due to the elongated footprint requiring more linear space on the roller.

Key Takeaway for Buyers: When calculating your ROI, do not just look at the machine's "rated speed" (which is 0–5 rpm for the die roller)66. You must calculate your daily throughput based on the specific capsule size you intend to manufacture.

Part 3: Anatomy of a Soft Capsule Production Line

A common misconception is that you only need the encapsulation machine. In reality, Soft Capsule Production requires a complete ecosystem of auxiliary machines (a "line") to handle preparation, encapsulation, and drying.

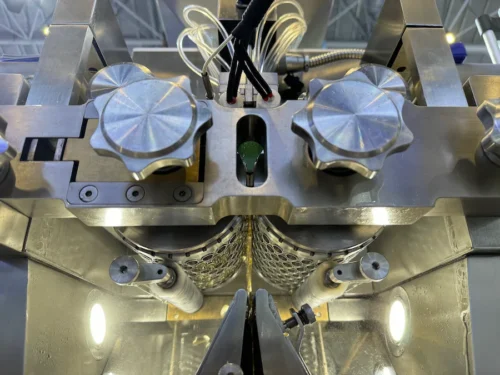

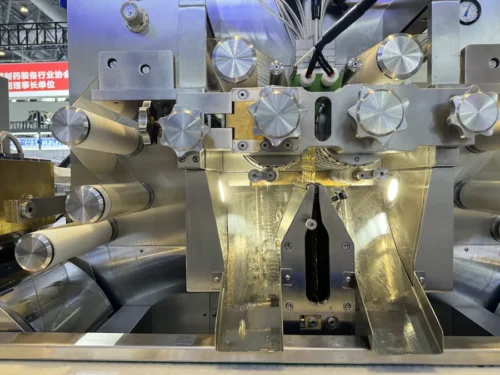

The mold part of the soft capsule machine

Here is the step-by-step workflow of the Grandpack RJWJ-115 line:

Phase 1: Preparation (The Kitchen)

Before any encapsulation happens, you must prepare the shell (gelatin) and the core (medicine).

- Gelatin Melting: The RJ-250 Gelatin-Melt Tank is used to cook the gelatin mass. It operates at temperatures up to 100℃ with a stirring speed of 35rpm to ensure consistency77.

- Vacuum Control: To prevent bubbles in the capsule shell, a Water-ring Vacuum Pump (SK-0.5) is used for defoaming88. This is aided by a Linear Condenser (LN-60), which cools steam and collects condensate water, effectively improving the stability of the vacuum system9.

- Medicine Prep: The Dosage Tank (PL-250) holds the active ingredients. It features a 3-layer jacket for heat preservation and uses compressed air discharge to reduce workshop height requirements1010.

- Homogenization: A Colloid Mill (JM-100) is used to grind and emulsify the raw materials, ensuring a smooth fill liquid1111.

Laboratory soft capsule machine

Laboratory soft capsule machine

Phase 2: The Core Process (Encapsulation)

This is where the magic happens.

- The Main Machine: The RJWJ-115 injects the liquid into the gelatin ribbons pressed between the die rollers.

- Thermal Regulation: A Water Chiller (Model CHDHU0200F) is critical here. It circulates cooling water (35L/min) to the casting drums to cool the gelatin ribbon into a solid film before it hits the die rolls1212.

- Material Transport: Once formed, the soft capsules are immediately blown out of the machine by the Capsule Blower1313.

Phase 3: Drying and Finishing

Fresh softgels are very soft and prone to deformation.

- Shaping: They are first transferred to the Tumble Dryer (DGZL-470). The rotation (0-50Hz) keeps the capsules moving so they don't stick together while they harden slightly1414.

- Final Drying: Finally, capsules are spread onto Drying Trays loaded onto Stainless Steel Trolleys for final curing in a drying room.

Part 4: Safety, Materials, and Build Quality

In the pharmaceutical industry, the machine is part of the product quality. If the machine reacts with the ingredients or flakes metal into the medicine, the batch is ruined.

Material Safety:

The RJWJ-115 production line is built strictly according to GMP (Good Manufacturing Practice) standards.

- Contact Parts: All parts that touch the medicine or gelatin, such as the Capsule Blower, Raw Material Storage Tank, Colloid Mill, and Trolleys, are made from Stainless Steel SS30416161616. This alloy is resistant to corrosion and easy to sanitize.

- Die Rollers: The critical die rollers are crafted from Aluminum Alloy, which provides the necessary hardness for cutting while being lightweight and non-reactive.

- Trays: The drying trays are made from PE (Polyethylene), a food-grade plastic that prevents capsules from sticking1818.

Component Reliability:

A machine is only as reliable as its electrical components. The RJWJ-115 utilizes a "Who's Who" of global automation brands1919:

- PLC: Omron (Japan) – The brain of the operation.

- Touch Screen: Weinview – For the Human-Machine Interface (HMI).

- Inverter: Delta – For precise speed control.

- Electrical Safety: Schneider (France) provides the breakers, contactors, and relays.

- Pneumatics: SMC (Japan) handles the air cylinders and valves.

Using these branded components ensures that if a relay or switch fails five years down the line, you can find a replacement part locally, rather than waiting weeks for a proprietary part from the manufacturer.

Part 5: Overview of the Pharmaceutical Machinery Market

The market for soft capsule production lines is evolving. Historically, high-output machines were massive, expensive, and required dedicated industrial facilities. However, the trend is shifting towards compact, versatile machines like the RJWJ-115.

Why the Shift?

- R&D and Pilot Batches: Large pharma companies need smaller machines to test new formulations without tying up their main production lines.

- Nutraceutical Startups: The explosion of the supplement market (CBD, Algae Oil, Vitamin D) has created a demand for "entry-level" professional equipment that fits in smaller cleanrooms (The RJWJ-115 is only 1.6m x 1m in footprint)2020.

- Flexibility: Manufacturers now prefer machines that can swap die rolls quickly to change from "20 Oblong" to "5 Tube" shapes to meet changing market demands.

Conclusion

Choosing the right soft capsule unit is a balance of science and strategy. You must begin with the end product: What Types of soft capsules does your market demand? Whether it is a "4 Oval" or a "20 Oblong" will dictate your production speed.

Furthermore, success lies in the integration. A high-quality encapsulation machine must be supported by a robust lineup of gelatin tanks, vacuum pumps, chillers, and dryers.

The Grandpack RJWJ-115 exemplifies this integrated approach, wrapping high-capacity engineering in a compact, GMP-compliant package equipped with top-tier components like Siemens and Omron.

Ready to launch your softgel product?

Understanding the technical parameters is the first step. Contact Grandpack today to configure a production line that matches your specific shape and capacity requirements.