Types of Soft Capsules & Production Line

Mastering Ointment Tube Filling & Sealing with the NF-150

How to Melt Gummies: A Guide to Rework & Production | Grandpack Machine

Author: Grandpack Machine Engineering Team | Category: Confectionery Production

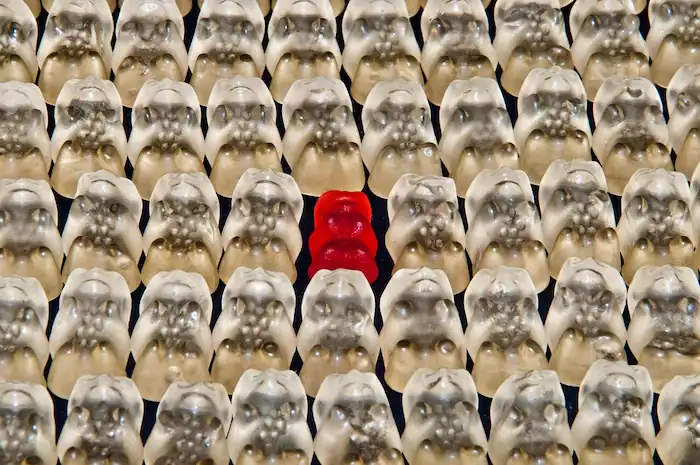

Gummies are deceptively simple. To the consumer, they are just chewy, colorful treats. But to a confectioner or a production manager, they are a complex matrix of hydrocolloids, sugars, and acids.

Whether you are a home baker wondering how to melt gummy bears for a dessert topping, or a factory manager looking to reduce waste by integrating a "rework" system into your soft gummy production line, the principle is the same: Heat destroys texture if not controlled.

In this guide, we move beyond the basics. We will explore the physics of remelting, why microwave methods fail at scale, and how professional gummy manufacturing machines handle the delicate process of reworking candy mass.

Part 1: The Chemistry of the Melt (Read This Before You Start)

Before you apply heat, you must identify your gelling agent. This is the most common mistake we see.

Gelatin-based Gummies: These are thermoreversible. Like ice turning to water and back to ice, gelatin can be melted and reset multiple times (within reason) without losing its structural integrity. This makes them ideal for melting and remolding.

Pectin or Starch-based Gummies (Vegan): These are generally thermo-irreversible. Once the pectin has set (gelled) in the presence of acid and sugar, breaking that bond with heat often destroys the texture permanently. If you try to melt these, you often end up with a sticky syrup that won't firm up again.

Pro Tip: If you are remolding gelatin gummies, remember that high heat degrades the "Bloom strength" (firmness). Every time you reheat gelatin, the final gummy becomes slightly softer.

Part 2: How to Melt Gummies at Home (Small Scale R&D)

If you are running a small R&D test or a home kitchen project, you lack the jacketed tanks of a factory. Here is how to mimic that precision manually.

The "Double Boiler" Method (Recommended)

This is the only way to melt gummies without caramelizing the sugar or creating a grainy texture.

Prep: Cut the gummies into small, uniform chunks. This increases surface area for faster melting.

The Setup: Place a glass or metal bowl over a pot of simmering water (bain-marie). Crucial: Ensure the water does not touch the bowl. You want steam heat, not contact heat.

The Process: Add the gummies. As they begin to sweat, add a teaspoon of water or neutral oil. This acts as a plasticizer to help the mass flow.

Agitation: Stir gently. Vigorously whipping air into the mix will create bubbles that won't escape once the gummy sets.

Why Avoid the Microwave?

While you can melt gummy bears in a microwave (50% power, 15-second bursts), we advise against it for quality results. Microwaves create "hot spots." One part of your bowl might be 40°C while another hits 120°C, scorching the sugar and degrading the gelatin instantly.

Part 3: The Industrial Perspective – Handling "Rework" at Scale

In a commercial setting, we don't call it "melting gummies"; we call it Rework Processing.

Every candy factory generates scrap—start-up waste, misshapen bears, or trim from cutting machines. Throwing this away is burning money. A modern soft gummy production line should be capable of recycling this material.

However, you cannot simply dump 50kg of finished gummy bears into a cooker. Here is how Grandpack Machine solves the challenges of industrial melting:

1. Precise Temperature Control (The Jacketed Tank)

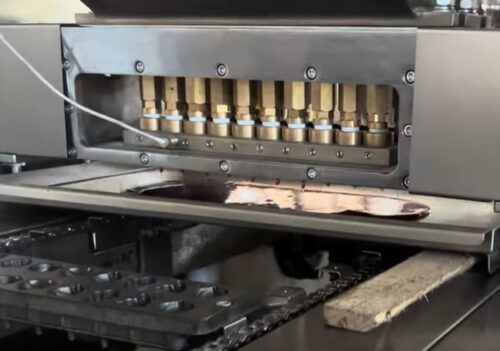

Unlike a stovetop, industrial Gummy Manufacturing Machines use jacketed cookers filled with thermal oil or steam.

The Advantage: The heat is distributed evenly across the entire surface of the tank. We can hold the mass exactly at 75°C (or your specific melting point) to liquefy the gelatin without burning the sugar.

2. High-Shear Agitation

Melting a solid block of gummy takes energy. Our tanks utilize variable-speed scrapers and homogenizers.

The Advantage: This mechanical action breaks down the solid gel matrix much faster than heat alone, reducing the time the product sits at high temperatures. This preserves the flavor profile.

3. Moisture Balancing

Finished gummies have a lower water content (roughly 18-20%) than the liquid syrup needed for depositing (which is usually around 75-80% Brix).

The Advantage: When reworking, our systems allow you to introduce exact amounts of water or fresh syrup to bring the "re-melt" back to the correct viscosity for the depositor.

4. Filtration

Reworked gummies might contain starch residue (from moguls) or oil/wax (from polishing).

The Advantage: Grandpack lines can be fitted with inline filters before the depositor to ensure no solid bits clog the injection nozzles.

Practical R&D Tip: The "10% Rule"

If you are a manufacturer planning to reuse scrap gummies, do not make a batch from 100% melted gummies. The texture will be rubbery and the clarity will be poor.

The Industry Standard: Dissolve your scrap gummies and blend them into a fresh batch of syrup. usually, a ratio of 10% to 20% rework mixed with 80% to 90% fresh syrup is the sweet spot. This maintains consistency in color, flavor, and shelf-life.

Conclusion: Consistency is King

Whether you are melting a handful of bears for a cake topper or processing tons of rework in a factory, the enemy is uncontrolled heat.

At Grandpack Machine, we design our equipment—from pilot-scale cookers to full-scale soft gummy production lines—to give you absolute control over temperature and viscosity. Because in the candy business, precision is what separates a sticky mess from a premium product.

Looking to upgrade your gummy production capabilities? Explore our range of jacketed cookers and depositing lines designed for both fresh production and efficient rework handling.