Top 10 Metal Detectors Suppliers in China

Why Metal Detection Machines Are Ideal for Pharmaceutical Packaging?

Tablet Coating Machine Export Case | Pharmaceutical | Health supplement

High-Efficiency Solutions for Middle East Pharma

"A coating machine unit is the preferred choice for large pharmaceutical companies due to its efficiency and safety in tablet coating. At GRANDPACKMACHINE, we provide professional export services and a comprehensive after-sales experience."

– Helen, Senior Sales Manager at GRANDPACKMACHINE Company

– Helen, Senior Sales Manager at GRANDPACKMACHINE Company

In the rapidly evolving pharmaceutical landscape, the demand for high-quality, efficient, and compliant machinery is paramount. This case study explores a recent success story where GRANDPACKMACHINE exported a state-of-the-art coating machine unit to a prominent pharmaceutical manufacturer in the Middle East. This project highlights our commitment to delivering advanced coating machine solutions that meet rigorous international standards while providing exceptional support throughout the export process.

Modernizing Tablet Production

Our client, a leading pharmaceutical company based in the Middle East, was looking to upgrade their production line. Their existing equipment was struggling to meet increasing demand, and they needed a solution that could guarantee uniformity, efficiency, and compliance with GMP standards. Specifically, they required a high-capacity coating machine unit capable of handling large batches while ensuring precise control over the coating process.

After a thorough consultation, we identified their need for a robust system that integrated seamlessly with their current operations. The key requirements included:

High-efficiency coating for various tablet sizes.

Precise temperature and airflow control to prevent defects.

An advanced control system for ease of operation and data logging.

A complete solution including air handling and exhaust systems.

The Solution: BG-150E High-Efficiency Tablet Coating Machine

To meet these exacting standards, we recommended and customized our BG-150E Tablet Coating Machine. This model is a pinnacle of modern pharmaceutical engineering, designed to offer superior performance in film coating, sugar coating, and organic solvent coating.

Key Technical Specifications

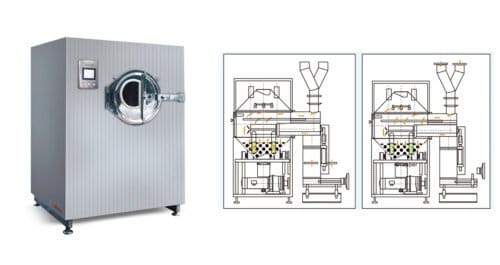

The BG-150E coating machine delivered to our client features a comprehensive array of advanced components:

Model: BG-150E, designed for high-capacity industrial applications.

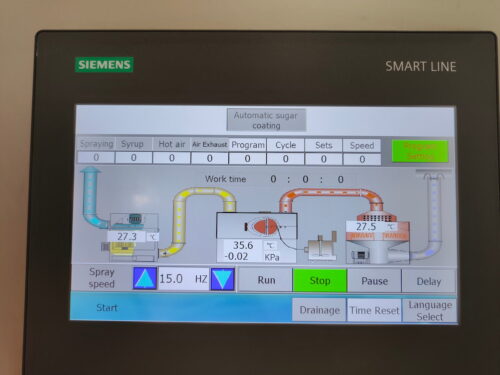

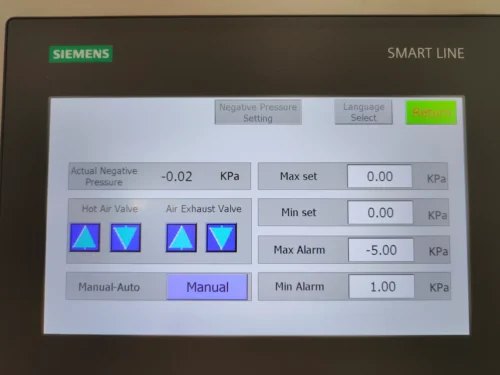

Control System: A sophisticated PLC combined with a user-friendly 10-inch touch screen. This interface allows operators to monitor and adjust critical parameters in real-time, ensuring batch-to-batch consistency.

Spray System: Equipped with 6 high-precision spray guns. This multi-gun setup ensures uniform coverage, reducing coating material waste and guaranteeing a flawless finish on every tablet.

Thermal Regulation: The unit includes a Thermal Stining Drum and is powered by a Steam Heating system. This configuration provides rapid and stable heat transfer, essential for drying tablets evenly without compromising their chemical integrity.

Air Handling: A dedicated Hot Air Cabinet and Air Exhaust Cabinet were integrated to manage the drying environment perfectly. This ensures that solvent vapors are efficiently removed, maintaining a safe and optimal coating atmosphere.

Fluid Delivery: A high-performance Syrup Pump ensures consistent delivery of the coating solution to the spray guns, preventing clogging and ensuring smooth operation.

Power Requirements: The system is engineered to operate on a 3-phase 380V 50Hz power supply, matching the industrial standard of the client's facility.

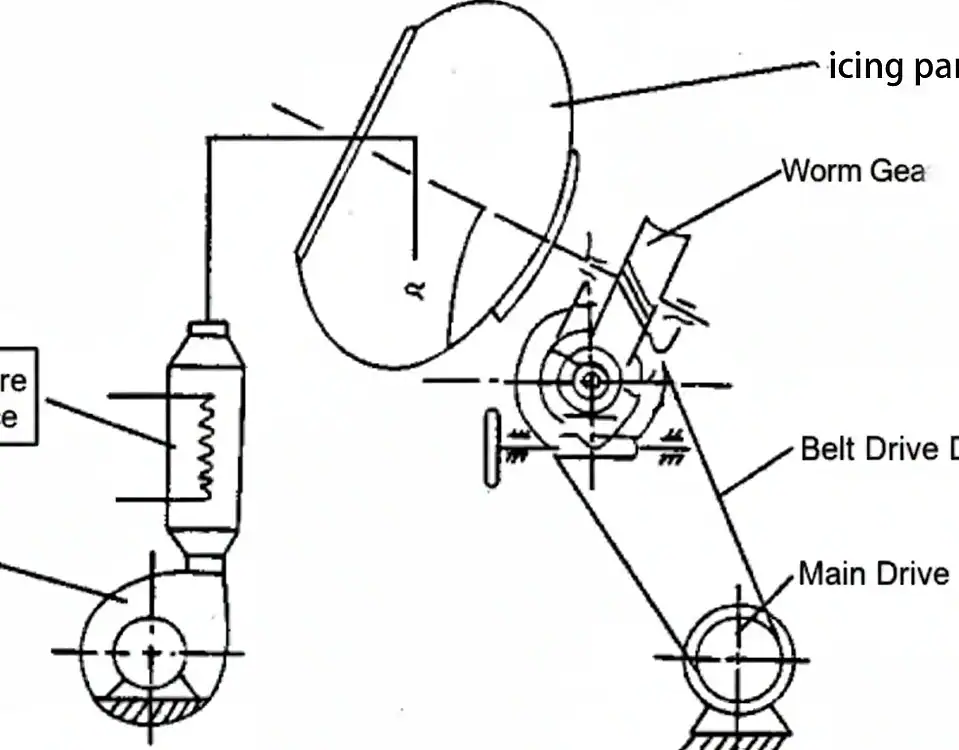

The Coating Machine Principle: How It Works

Understanding the coating machine principle is key to appreciating the BG-150E's efficiency. The process begins with the tablet cores being loaded into the clean, rotating drum. As the drum rotates, the streamline guide plates ensure the tablets tumble smoothly and frequently, exposing all surfaces.

Coating machine control panel - Siemens

Simultaneously, the spray guns atomize the coating solution into a fine mist, directed onto the tumbling tablet bed. The Hot Air Cabinet delivers filtered, heated air through the tablet bed, which rapidly evaporates the solvent. The Air Exhaust Cabinet then draws out the moist air. This continuous cycle of spraying and drying allows a thin, uniform, and solid film to form on the surface of each tablet. The BG-150E's precise control over spray rate, inlet air temperature, and drum speed ensures that common issues like sticking, picking, or orange-peel effects are eliminated.

Applications of Coating Machines in Pharma and Beyond

While this specific case focuses on pharmaceuticals, the applications of coating machines extend far beyond.

Pharmaceuticals: Used for masking unpleasant tastes, protecting drugs from environmental factors (light, moisture), and controlling drug release (enteric coating).

Nutraceuticals: Coating vitamin and mineral supplements for easier swallowing and better stability.

Food Industry: Used in confectionery for sugar coating candies and chocolates.

Agriculture: Coating seeds with fertilizers or pesticides to improve germination and crop yield.

The versatility of the BG-150E makes it a valuable asset for any manufacturer looking to enhance product quality and shelf life.

The Export Process: A Coating Machine Export Case Study

Navigating the logistics of a coating machine export case study involves more than just shipping a crate. For this Middle East project, GRANDPACKMACHINE handled every step to ensure a seamless experience.

Dust removal cabinet

Consultation & Customization: We worked closely with the client to tailor the BG-150E to their specific voltage and layout requirements.

Manufacturing & QA: The machine underwent rigorous testing in our factory. We simulated the client's production environment to ensure all 6 spray guns, the PLC system, and the Steam Heating mechanism functioned perfectly.

Packaging & Shipping: Given the size and sensitivity of the coating machine unit, we used reinforced, export-grade wooden crates. Special care was taken to protect the 10-inch touch screen and electronic components from humidity and physical shock during sea freight.

Documentation: We provided all necessary documentation, including IQ/OQ (Installation Qualification/Operational Qualification) protocols, CE certificates, and detailed operation manuals in English, facilitating a smooth customs clearance and validation process at the destination.

Why Choose a Grandpack Machine?

This coating machine outlet to the Middle East demonstrates our capability to deliver world-class machinery. Our clients choose us because we offer more than just hardware; we offer a partnership.

Expertise: With years of experience in the coating machine sector, we understand the nuances of pharmaceutical manufacturing.

Reliability: Our machines, like the BG-150E, are built with top-tier components (like the Siemens PLC and specialized spray guns) to ensure longevity and minimal downtime.

Support: As Helen mentioned, our service doesn't end at the sale. We provide remote guidance for installation, on-site commissioning options, and a responsive spare parts service.

Conclusion

The successful installation of the BG-150E coating machine in the Middle East stands as a testament to GRANDPACKMACHINE's quality and service. For pharmaceutical companies looking to optimize their coating processes, our solutions offer the perfect blend of technology, efficiency, and reliability.

Whether you are looking for a standalone unit or a complete production line, GRANDPACKMACHINE is your trusted partner for high-quality pharmaceutical machinery.

Are you ready to upgrade your production line? Contact us today to learn more about our coating machine solutions and how we can support your business goals.