The Secrets Behind the High-Performance Soft Capsule Machine

How to Obtain the Perfect Capsule? | Grandpack

Homogenize the paste using a Emulsifier | Grandpack

How Are Paste Products Evenly Mixed?

Mixing thick pastes for cosmetics and ointments demands a precise emulsifier. The Grand Emulsifier (model CBZRJ-200L) is a vacuum homogenizer that combines high‐speed mixing with vacuum degassing.

By applying the emulsifier principle of high-shear homogenization under vacuum, it removes air bubbles and disperses oil and water phases uniformly. This ensures every batch of cream or lotion has a stable, smooth texture. The result? Consistent quality and texture in each batch, exactly what industrial buyers and cosmetics manufacturers need.

Emulsifier Principle: How Uniform Mixing Happens

The emulsifier principle relies on two key actions: intensive shear mixing and vacuum degassing. First, a powerful rotor–stator homogenizer breaks droplets into fine particles, while an agitator and wall-scraper stir thoroughly. At the same time, vacuum pumps pull air out of the mix. Removing air prevents bubbles and oxidation, yielding a void-free, stable product. Manufacturers can adjust speed and temperature via the control panel, giving precise control over the final paste.

Tip: Adjustable mixing speed and temperature on a vacuum emulsifier give you precise control over your product’s quality. In practice, this means smoother creams and consistent textures batch after batch.

The vacuum emulsifying process also integrates heating and cooling. The tank jacket heats materials (up to ~130 °C) to improve solubility, then cools the mix as needed. By tightly controlling temperature, the mixer achieves the desired viscosity and stability. In short, the Grand Emulsifier applies the emulsifier principle in one machine: blending oil and water thoroughly while eliminating air.

Key Features of the Grand Emulsifier (CBZRJ-200L)

Components of the Grand Emulsifier CBZRJ-200L: main treatment pot, high-shear agitator, vacuum pump, and digital control panel.

- Large Mixing Capacity:250 L stainless steel main vessel (200 L working volume) handles batch production.

- High-Speed Homogenizer:4 kW emulsifying motor spins up to 3,500 RPM, delivering powerful shear for fine dispersion.

- Efficient Heating/Cooling:Dual jackets allow heating up to 130 °C and circulating coolant, so you can preheat raw materials or cool finished paste rapidly.

- Vacuum System:A 2.35 kW vacuum pump (2BV2070) creates –0.1 MPa inside the pot, pulling out air bubbles for a smooth, air-free product.

- Dual Pre-mix Pots:Separate oil (100 L) and water (120 L) tanks (each with turbine agitators) let you heat and stir ingredients before mixing.

- User-Friendly Control:Intuitive digital panel controls mixing speed, time, temperature and vacuum level for repeatable precision.

These features combine to deliver uniform mixing and high product quality. For example, the turbine agitator scrapes the vessel wall while the homogenizer blends, ensuring no raw material sticks or stratifies. The result is an even, cream‐like consistency every time.

How It Works: Paste Preparation and Emulsification

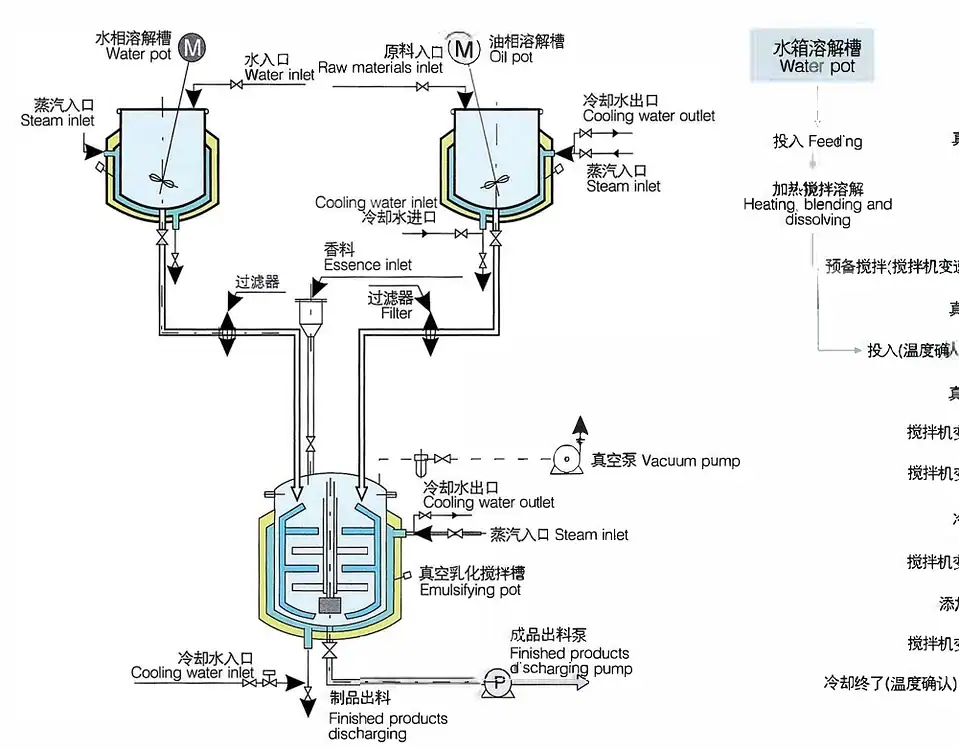

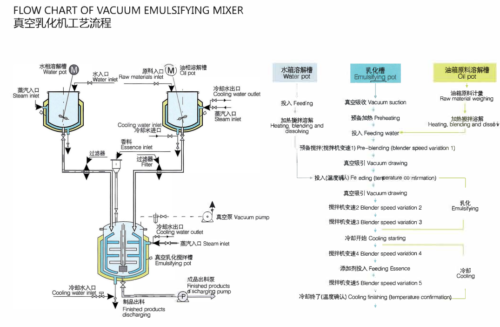

Flow chart of the vacuum emulsifying mixer process: separate oil and water pots feed into the emulsifying vessel under vacuum.

During paste preparation and emulsification, raw ingredients are fed and combined in a controlled sequence:

- Material Feeding:Oil and water phases (with active ingredients dissolved or dispersed) are loaded into separate pre-heated vessels.

- Vacuum Creation:The main mixing pot is sealed and vacuum is applied, removing air and preventing oxidation.

- High-Shear Homogenization:The rotor–stator homogenizer is activated at high RPM, breaking down droplets into a fine emulsion.

- Dual Agitation:Simultaneously, the slow agitator (with scraper blades) stirs the mix, ensuring continuous circulation and preventing dead zones.

- Temperature Control:Jacketed heating or cooling adjusts viscosity mid-process, optimizing stability (e.g. cooling down as the batch nears completion).

- Final Discharge:Once mixed, the vacuum is released and the uniform paste is discharged.

This step-by-step process guarantees that paste preparation and emulsification occur under ideal conditions. The vacuum step is critical: by pulling out bubbles, it yields a smooth emulsion free of voids or foam. Meanwhile, controlled shear ensures ingredients blend homogeneously (no unmixed pockets). In summary, the Grand Emulsifier’s workflow – from separate pre-heating to vacuum homogenizing – is designed for consistent, high-quality paste mixing.

Application Range of Emulsifiers

Sample emulsified products (creams, lotions, ointments, gels) produced by vacuum emulsifying mixers.

The application range of emulsifiers like the CBZRJ-200L is broad. This vacuum mixer is ideal for cosmetic and pharmaceutical pastes: face creams, lotions, ointments, shampoos, and gels. It can even handle toothpaste and heavy creams (up to ~50,000 cp viscosity). Common product types include:

- Creams & Lotions: Skin creams, serums, body lotions – all require smooth, consistent texture.

- Gels & Ointments: Gel-based cleansers and medicated ointments benefit from the air-free, uniform mix.

- Personal Care & Beauty: Shampoos, conditioners, mascaras, and other emulsions that mix oil and water.

- Pharmaceutical and Food Pastes: Nutraceutical gels, pharmaceutical ointments, food dressings – any viscous emulsion.

For example, manufacturers use the CBZRJ-200L to create silky creams and lotions with no visible bubbles, improving shelf life and appearance. The vacuum emulsifying process removes air that would otherwise cause foaming, so end products look clearer and last longer. In practice, this means products like aloe gels and moisturizers have uniform color and feel, batch after batch.

Benefits for Manufacturers

Vacuum emulsifiers offer several key advantages:

- Consistent Quality:High shear mixing and vacuum combine to give homogeneous blends. Every jar of cream or tube of ointment has the same texture and stability.

- Improved Stability:Removing air and controlling temperature means less oxidation and longer shelf life.

- Efficiency:The process is energy-efficient under vacuum, so it uses less power than non-vacuum mixers. The CBZRJ-200L’s robust agitation also speeds up mixing time without sacrificing quality.

- Versatility:You can adjust speed, temperature, and vacuum for different formulas. This flexibility lets you switch between products (e.g., lotion one day, heavy cream the next) with minimal changes.

- Hygiene and Safety:The mixer’s 316L stainless steel contact parts are easy to clean and meet sanitary standards. The closed mixing environment prevents contamination.

Industry Tip: A vacuum homogenizing mixer like the CBZRJ-200L ensures that every batch of cream or lotion meets quality standards by eliminating air pockets and achieving uniform droplet size.

In summary, the Grand Emulsifier (CBZRJ-200L) combines proven emulsifier principles with heavy-duty engineering. Its integrated system of high-speed homogenizer, vacuum pump, heating/cooling jackets, and agitation makes paste products perfectly even. For cosmetics manufacturers and industrial users, this means higher yields of premium-quality creams, lotions and ointments – with greater consistency and less waste.

References:

Vacuum Emulsifying Tank Applications in Pharmaceutical Manufacturing