Homogenize the paste using a Emulsifier | Grandpack

The 2026 Flu Surge: How Pharma Machinery is the Frontline Defense Against the H3N2 Variant?

How to Obtain the Perfect Capsule? | Grandpack

In the competitive world of pharmaceutical and nutraceutical manufacturing, appearance matters. When a consumer opens a bottle of vitamins or medication, they expect pristine, dust-free, and shiny capsules. They do not want to see powder residue or empty shells. This leads us to a critical question for production managers: How to obtain clean capsules that meet strict GMP standards?

The answer lies at the end of your filling line. It requires more than just a good filler; it requires a robust, high-performance capsule polishing machine.

At Grand Machinery, we understand that the finishing touches define product quality. Whether you are producing hard gelatin capsules filled with herbal powder or chemical drugs, the polishing stage is where your product becomes market-ready.

The Challenge: Dust, Static, and Defects

Before we dive into the solution, we must understand the problem. During the capsule filling process, excess powder often clings to the exterior of the capsule shell. Static electricity can cause capsules to stick together. Furthermore, high-speed filling machines occasionally produce empty or lightweight capsules that must not reach the consumer.

How to obtain the perfect capsule involves three critical steps:

Capsule dust removal: Cleaning the surface.

Polishing: enhancing the gloss and finish.

Sorting: Removing empty or defective shells automatically.

This is where specialized machinery becomes essential. You cannot achieve this consistency manually. You need an automated solution integrated into your production line.

The Solution: Grand Capsule Polishing Machines

A capsule polishing machine is a specialized device designed to clean, polish, and often sort capsules immediately after they leave the filling machine. At Grand Machinery, we offer a range of solutions tailored to different production needs, from standard polishers to vertical lifting systems.

1. The Power of Automatic Sorting: The JFP-110A

For high-volume manufacturers, the JFP-110A Capsule Sorting and Polishing Machine is a game-changer. It is not just a cleaner; it is a quality control station.

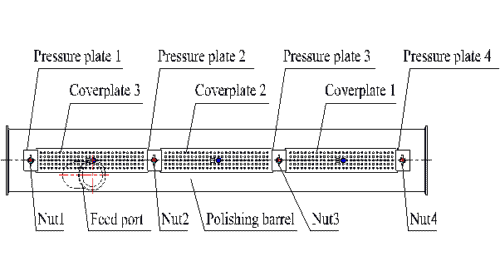

How it Works: The JFP-110A is designed with a sorting function. As capsules enter the machine, they pass through a polishing chamber. Here, a rotating brush gently cleans the capsule surface. But the real magic happens with the sorting mechanism.

Automatic Rejection: The machine utilizes a novel negative pressure device. This vacuum system is calibrated to automatically reject ultra-lightweight capsules, fragments, and empty capsules.

Static Elimination: The friction of polishing can create static. The JFP-110A is engineered to eliminate static electricity, ensuring capsules flow freely.

Capacity: This machine is a beast, boasting a productivity of 300,000 pieces per hour.

One common issue in older machines is jamming. The JFP-110A solves this with a new type of net cylinder that ensures no jammed capsules during operations. Furthermore, the capsules do not directly contact the metal net, which effectively protects the printed text or logos on your capsules.

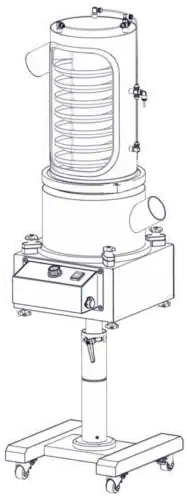

2. Space-Saving Efficiency: The LFP-150C Vertical Polisher

In many factories, floor space is at a premium. You might need to move capsules from a low-level filler to a high-level metal detector or hopper. This is where the LFP-150C Vertical Capsule Polishing Machine shines.

This machine offers a dual function: polishing and lifting.

Design Flexibility: The machine’s inlet and outlet can be adjusted 360 degrees in a circle. This allows you to fit the machine into tight corners or complex line layouts, saving valuable production space.

High Throughput: It is capable of handling up to 450,000 capsules per hour

Seamless Connection: Because it lifts the product, it leaves height space to connect subsequent equipment. The outlet is positioned at 1100mm (customizable), making it perfect for feeding directly into a Automatic capsule sorting device or a metal detector

Like the JFP series, the LFP-150C also features a capsule sorting device that automatically selects out lightweight or empty shells and separated bodies/caps.

3. The Reliable Standard: The YJP-A

For manufacturers who need a straightforward, effective solution, the YJP-A Capsule Polishing Machine is the industry standard. It effectively removes dust from the capsule surface to improve the finish.

GMP Compliance: The parts in contact with medicine are manufactured from 316L stainless steel, fully meeting GMP requirements.

Adjustability: Like our other models, it can be adjusted 360 degrees for easy installation.

Performance: With a productivity of 150,000 pieces per hour, it is ideal for small to medium batch production.

Industry Applications: Why You Need This

These machines are not limited to just one type of product. They are widely used across the Health product (Nutraceutical) and Medicine (Pharmaceutical) sectors.

Health Products and Nutraceuticals

The market for fish oil, herbal supplements, and vitamins is booming. Consumers associate shiny, clean capsules with potency and purity. If your capsules are dusty, they look old or contaminated. Using a capsule polishing machine ensures your brand maintains a premium image.

Pharmaceutical Mass Production

In pharma, precision is law. You cannot risk an empty capsule making it into a blister pack. The Automatic capsule sorting features of the JFP and LFP series provide that extra layer of security. By removing empty shells before they reach the packaging line, you prevent costly downtime and quality control failures downstream.

Integrating into Your Production Line

How to obtain clean capsules efficiently? You automate the transfer.

Grand polishing machines are designed for "linkage" production.

Input: The height and angle of the JFP-110A can be adjusted to fit into any chute of capsule filling machines or tablet presses. This means products are polished immediately after production.

Output: The machines are equipped with special discharge devices that can connect directly to full-automatic filling lines.

For example, a typical line might look like this:

Capsule Filling Machine - LFP-150C Vertical Polisher -Metal Detector - Bottle Filling Machine.

This seamless integration reduces manual handling, which is a key requirement for GMP compliance. All main parts of our machines utilize quick-connection devices, allowing for rapid disassembly and cleaning.

Expert Insight: The Grand Difference

Choosing the right equipment provider is just as important as choosing the right machine. You need a partner who understands the entire lifecycle of the product.

As Helen Xiao, our Sales Manager at Grand, points out:

"We have been focusing on pharmaceutical machinery for 19 years. From capsule manufacturing to packaging, we provide a full set of production equipment and are a partner of many health care companies and pharmaceutical manufacturers."

This expertise ensures that when you ask about capsule polishing machine price or technical specs, you are getting advice based on nearly two decades of field experience. We don't just sell machines; we help you optimize your entire production flow.

Factors Influencing Capsule Polishing Machine Price

When researching capsule polishing machine price, you will find a range of options. Understanding what drives the cost will help you make a smart investment.

Functionality: A machine that polishes and lifts (like the LFP-150C) or polishes and sorts (like the JFP-110A) will cost more than a basic polisher (YJP-A). However, the sorting function saves money in the long run by reducing waste and labor.

Materials: High-quality stainless steel (304 or 316L) is non-negotiable for pharma. Cheaper machines might use lower-grade metals that corrode or fail GMP audits.

Components: Our machines use branded components. For example, the JFP-110A uses a standard motor from Xiamen Jingyan, a breaker from Chint, and a frequency converter from Taiwan Shihlin. Quality components ensure longevity.

Speed: Higher throughput (e.g., 450,000 pcs/hour) requires more robust motors and larger sorting chambers.

Maintenance and Cleaning: Keeping it GMP Compliant

A major concern for buyers is: "Is it hard to clean?"

Capsule dust removal means the machine itself gets dirty. If it's hard to clean, you risk cross-contamination.

Grand machines are designed for "Quick Disassembly."

The JFP-110A uses a new type of brush that is durable and easily changed.

The LFP-150C features a detachable main shaft brush, ensuring thorough cleaning with no dead corners.

All components use fast-connection devices for rapid removal.

This design philosophy means your operators spend less time scrubbing and more time producing.

Can It Polish Tablets?

While the primary focus is capsules, many clients ask about a tablet polishing machine. (Interested customers can take a look at our rotary screen machine) The JFP-110A is versatile. It is a newly designed unit described as a "Capsule Polisher to polish capsules and tablets". While tablet de-dusting often uses slightly different vibration principles, this machine is capable of handling tablet polishing needs, making it a versatile asset for contract manufacturers who run both dosage forms.

Conclusion: The Final Step to Quality

So, How to obtain the perfect capsule? You treat the polishing stage with the respect it deserves. You invest in machinery that not only cleans but also sorts and integrates with your line.

Whether you need the vertical lifting power of the LFP-150C, the robust sorting of the JFP-110A, or the reliability of the YJP-A, Grand Machinery has the solution.

Don't let dust and static compromise your brand reputation. Ensure every capsule that leaves your facility is flawless.

Ready to upgrade your production line?

Contact Grand Machinery today to discuss your specific needs and get a competitive quote on a capsule polishing machine. Let us put our 19 years of experience to work for you.

"We have been focusing on pharmaceutical machinery for 19 years. From capsule manufacturing to packaging, we provide a full set of production equipment and are a partner of many health care companies and pharmaceutical manufacturers."

"We have been focusing on pharmaceutical machinery for 19 years. From capsule manufacturing to packaging, we provide a full set of production equipment and are a partner of many health care companies and pharmaceutical manufacturers."