The 2026 Flu Surge: How Pharma Machinery is the Frontline Defense Against the H3N2 Variant?

What Makes a Great Visual Inspection Machine?

In pharmaceutical and cosmetics manufacturing, quality control is non-negotiable. A cutting-edge visual inspection machine brings automation, speed, and consistency to product inspection on the production line. By combining high-resolution cameras, advanced lighting, and AI-driven analysis, these systems catch defects that human inspectors might miss.

For example, Grand Pack’s GV1300 inspection machine uses deep-learning AI and multi-spectral vision to empower cosmetic, food, and pharmaceutical makers with “100% zero-defect delivery” at unmatched speed. In practice, an automated visual inspection system can scan hundreds of units per minute with micron-level precision, far outpacing manual checks.

As Helen, Grand Pack’s sales manager, notes, the company’s machines use “vision + AI deep learning” so that inspection results are quantitative and reliable, reflecting their decades of focus on pharma and cosmetics packaging.

Visual inspection isn’t just about snapping a picture. Modern automated visual inspection systems use synchronized lighting and optics to reveal flaws on every surface. Specialized backlighting and low-angle lights, for instance, allow a machine to “see through” reflections and check fill levels in clear bottles. High-end systems can even analyze transparent or glossy materials by filtering out optical noise.

In short, a great vision inspection machine must make defects visible and measurable under real production conditions. Such systems don’t get fatigued, and they operate 24/7 with perfect consistency – every unit is judged by the same AI-driven criteria. This level of repeatability is especially important in regulated industries where every product must meet strict quality standards.

Core Features of High-End Inspection Systems

A top-tier automated visual inspection machine will integrate several key capabilities to ensure thorough quality control. Procurement teams should look for features such as:

- Advanced AI Vision:High-resolution cameras (often multi-spectral) plus deep-learning algorithms let the system detect tiny or complex defects. Traditional systems struggle with shiny or transparent materials, but AI-driven models can “penetrate reflective surfaces and ignore visual noise”. In practice, this means catching fine scratches, bubbles, black spots, or missing print that would otherwise be missed.

- 360° Multi-Angle Coverage:One machine can inspect all sides of a part. For example, a single unit may incorporate 7–10 cameras to examine cap threads, bottle sides, and bases in one pass. This eliminates the need for separate inspection stations. A comprehensive system checks for surface contamination, physical damage, mold flash, deformations, and even missing internal text or codes.

- High Throughput:Modern vision systems keep up with fast production. Many machines inspect hundreds of items per minute; one example handles 200–400 pieces per minute standard, with options up to 600 ppm. Throughput scales with demand so quality control never creates a bottleneck. Continuous-flow tracking and smart reject mechanisms ensure that as soon as a flaw is detected, the bad unit is removed in real time.

- Easy AI Training:Changing products shouldn’t require re-programming engineers. Leading systems offer a code-free interface where technicians simply feed a handful of sample products. The onboard AI “automatically builds a new inspection model” from labeled examples, often in under 30 minutes. This means the inspection machine can quickly adapt to new bottle shapes, cap styles, or packaging designs with minimal downtime.

- Intelligent Diagnostics:Unplanned downtime is very costly. Top machines monitor their own health constantly. Built-in sensors and software alert maintenance staff before a failure occurs. For example, the GV1300 model features self-diagnostics that forecast component issues, allowing convenient scheduling of service and maximizing uptime. This “intelligent self-diagnostic system” keeps quality control running smoothly around the clock.

High-end red wines often have high requirements for their outer packaging and bottle opening. - Visual Inspection of wine bottles

By combining these features, a great visual inspection machine performs like a “smart eye” on the line, flagging defects that human inspection might miss. According to industry comparisons, such high-efficiency vision systems achieve near-perfect repeatability and accuracy. They maintain “100% repeatable inspection, 24/7” consistency at production speeds far beyond manual labor. This translates into a reliable visual inspection machine that becomes indispensable for quality assurance.

Benefits of Automated Inspection for Pharma & Cosmetics

For decision-makers, upgrading to automated vision inspection systems yields tangible benefits:

- Improved Quality and Compliance:Automation ensures every item is checked the same way. Defect detection accuracy can reach sub-millimeter scales, catching flaws too small for the eye. False rejects drop dramatically because the AI differentiates harmless variations from true defects. Over time, companies see fewer recalls or customer complaints – a key priority in pharma and cosmetics where brand reputation hinges on flawless products.

- Labor Savings and ROI:Replacing manual checks with machines immediately cuts labor costs. Grand Pack notes that their inspection machines let customers “dramatically reduce costs” tied to manual labor, rework and product recalls. In one scenario, running at 200 bottles per minute with only a 2% false-reject rate still throws away 4 good bottles per minute – a waste of 240 bottles an hour. Intelligent vision software can almost eliminate such losses, yielding fast return on investment. One evaluation observes that savings on labor and recall avoidance pay back the equipment cost quickly, while consistently guarding the brand’s reputation.

- Data and Traceability:Modern machines record inspection data in detail. Instead of just counting rejects, they categorize defect types and log every trigger. This insight allows the team to fix upstream issues (e.g. a capper out of adjustment) and continuously improve the process. Digital records also help with audits and compliance – a major plus for regulated industries.

- Higher Throughput and Adaptability:Automated systems can scan up to 100 items per minute or more (compared to ~10–15/min by hand). They easily keep pace with expanded production lines. When a new product is introduced, the quick re-training capability means inspection can resume in minutes. This scalability helps procurement teams future-proof their lines: the inspection machine grows with new products and higher volumes.

- Reduced Risk:Ultimately, investing in a visual inspection system is like buying insurance. It guarantees defect-free delivery to customers (“zero-defect delivery” as one OEM promises) and protects patients and consumers from faulty products. In high-stakes pharma production, even tiny contaminants can be critical, and vision inspection machines are the frontline defense.

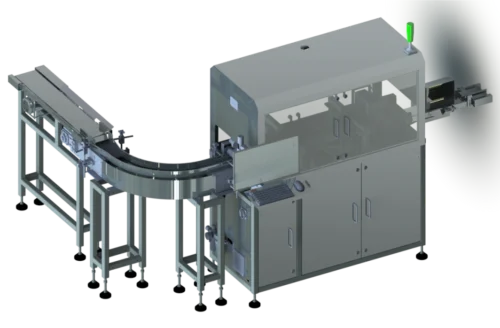

GV1600: 360° Bottle and Container Inspection

The GV1600 is an AI-powered visual inspection machine designed for inspecting cosmetic and pharmaceutical containers. It uses multiple synchronized cameras to scan bottles from every angle — inspecting the neck, body, and base of each container. Equipped with Grand Pack’s proprietary SVISION AI, the GV1600 identifies defects like fine scratches or “wire drawing” marks, scuffs, trapped air bubbles, black spots, missing plastic or glass, and flash (mold burrs) on bottles. It can even check for uneven glass thickness or missing printing on the cap.

One machine can handle many bottle formats: both PET plastic and glass bottles of various sizes used in cosmetics (lotions, serums, shampoos) or pharma (vials of liquid medicine) pass through the same system with simple adjustments.

By replacing tedious manual checks with automated 360° camera inspection, the GV1600 dramatically boosts line throughput (up to 150 parts/min) while reliably sorting out flawed containers. Its flexibility means it suits everything from shampoo bottles to injectable vials – essentially any cylindric container that needs perfect integrity.

GV1700: Inspection of Wrapped Packaging

The GV1700 specializes in inspecting shrink-wrapped boxes and cartons. This machine is ideal for outer cartons used in cosmetics (such as mask boxes, lotion/toner boxes, tube boxes, or cream boxes).

It focuses on the packaging film that wraps these cartons. Using AI vision, the GV1700 detects torn or missing shrink film, misaligned sealing, wrinkles or creases in the wrapping, and even the presence or positioning of pull-tabs and tamper bands.

For example, it flags a missing strip of film on the bottom seam, a crooked pull-tab, or a diagonal seal on a lid. By automating this process, the GV1700 replaces slow manual film inspection. The result is fewer customer complaints and rejections due to damaged packaging – a critical benefit for brand image in beauty products.

Like the GV1600, it leverages the vision + AI deep-learning approach that Grand Pack emphasizes, turning visual inspection into quantifiable, data-driven output. In Helen’s words, these machines enable “product inspection to achieve quantitative output,” ensuring that every box leaving the line meets quality standards.

Industry Applications and the Pharma Angle

Both the GV1600 and GV1700 have clear uses in cosmetics, but they also apply to pharmaceutical lines. In pharma, a visual inspection machine can check ampoules, vials, blister packs, and syringes. For instance, the same bottle-inspection technology of the GV1600 can be configured to inspect drug vials for chips or particulate matter in solution.

The GV1700’s film-detection approach can be used for sterile blister seals, ensuring patient safety. In fact, Grand Pack highlights that their vision systems serve “pharmaceutical manufacturers” as well as cosmetics. By integrating these machines into a pharmaceutical production line, manufacturers ensure compliance with standards (like FDA or USP guidelines on visible particle inspection) and protect end users. The key advantage is the same: automated vision adds a layer of quantitative quality assurance that human inspection alone cannot match.

For pharmaceutical manufacturers, Visual Inspection of drug bottles ensures consistency and efficiency in drug production.

Choosing the Right System

When evaluating automated visual inspection systems, procurement professionals should partner with a specialist vendor. Key questions to ask include: Does the system support your product shapes? Can the AI adapt quickly to new items? How are lighting and cameras customized? Grand Pack, for example, designs its machines for specific industries. As one white paper notes, inspecting a transparent cosmetic bottle or a viscous emulsion requires tailored optics and algorithms. In practice, companies find that a machine dedicated to their product type (e.g. the GV1900 for glass bottles or GV2000 for emulsions) yields far fewer false rejects and misses. The right provider will also offer training support and integration help. Ultimately, the best visual inspection machine is one that meets your product’s unique needs – whether it’s high-speed beverage vials, transparent serum bottles, or intricately wrapped cosmetic boxes.

Conclusion

A great visual inspection machine is more than just a camera on the line — it’s an intelligent quality control partner. In summary, decision-makers should look for machines that combine advanced AI and imaging with full 360° coverage, high throughput, and easy adaptability. These machines dramatically improve defect detection (often down to microns), free up labor, and ensure regulatory compliance. As industry comparisons show, a top-tier system provides much higher consistency and speed than manual or basic sensor inspections. The GV1600 and GV1700 exemplify these principles for cosmetics and pharma packaging. They replace error-prone manual checks with automated, data-driven inspection, from sealed box films to every bottle surface. In the words of Grand Pack’s manager Helen: their vision systems use AI deep learning to make inspection results quantitative and reliable. For any pharma or beauty production line aiming for zero-defect output, investing in a robust automated visual inspection system is not optional – it’s the standard for excellence.

Sources: Industry-leading vision inspection solutions.

- GV1300 AI Bottle Cap Auto Inspection Machine |Vision Systems

- High-Efficiency Vision Inspection Machines for Cosmetics