Fluidized Bed Pharmaceutical Granulator

Achieve unparalleled efficiency and consistency in your solid dosage manufacturing with Grand state-of-the-art Fluidized Bed Granulator (FBG). Engineered for the demanding standards of the pharmaceutical, food, and chemical industries, this system seamlessly integrates mixing, granulation, and drying into a single, automated process. By combining these critical steps, our FBG technology dramatically reduces processing time, minimizes material handling, and lowers the risk of cross-contamination, delivering superior granule quality in a cGMP-compliant environment.

Contact Us

Detailed Description

Our Fluidized Bed Granulator is more than just a piece of equipment; it's a comprehensive solution for producing uniform, free-flowing granules with exceptional consistency. The process begins with our advanced air handling unit, which features a three-stage filtration system to ensure the process air is free of particulates, protecting the integrity of your product. With flexible electric or steam heating options, you can achieve precise temperature control, which is vital for reproducible results and protecting heat-sensitive active ingredients.

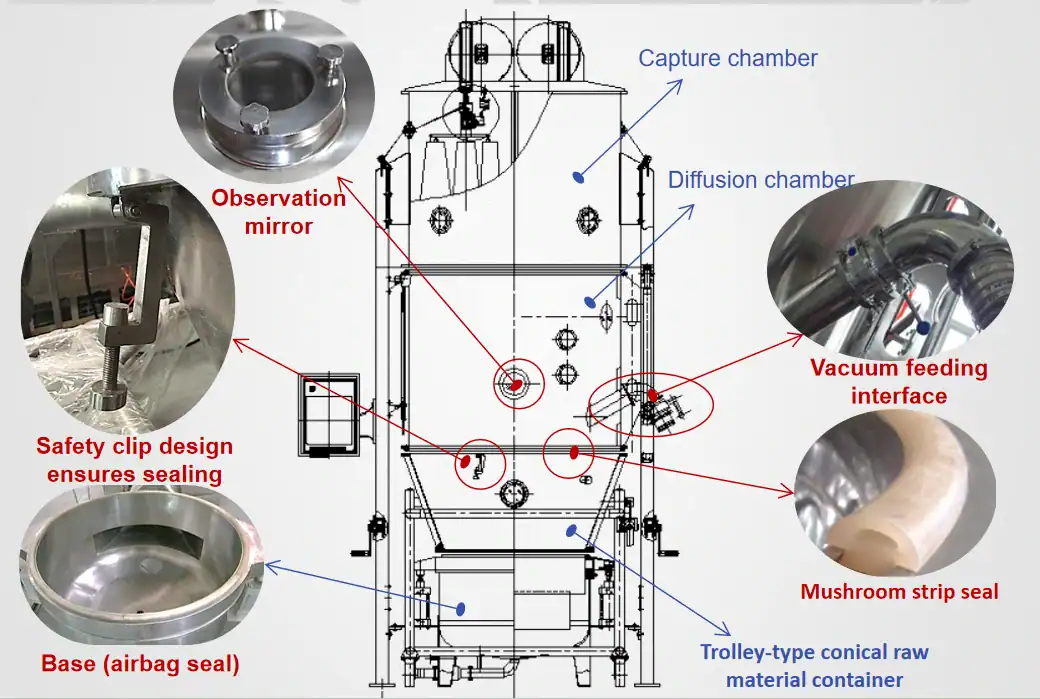

The "one-step" or "single-pot" granulation is performed in a closed system. Materials are loaded efficiently via a sealed, pressure-reduced feeding mechanism, ensuring containment and operator safety. Inside the product container, particles are fluidized by a carefully controlled upward stream of heated air. A high-precision nozzle sprays the binder solution onto the suspended particles, causing them to agglomerate and form granules. The process is continuously monitored and adjusted by the automated control system, ensuring optimal conditions from start to finish. Once granulation is complete, the system transitions to the drying phase in the same chamber, resulting in finished granules ready for the next stage of production.

Fluidized bed host system

Features

Precision Process Control Our granulator provides exacting control over every critical parameter. An intuitive air intake control valve allows for fine-tuning of airflow and fluidization velocity, while the precision heating system maintains stable temperatures. This level of control results in consistent particle size distribution, bulk density, and flowability, batch after batch.

Intelligent Automation & Data Integrity (21 CFR Part 11 Ready) At the heart of the granulator is a powerful PLC system coupled with a user-friendly Human-Machine Interface (HMI). This provides complete automation and real-time monitoring of the entire granulation process. The system is designed for compliance, allowing you to easily store, export, and print critical process parameters and batch data, ensuring a clear audit trail for regulatory requirements.

Automated Cleaning for Maximum Uptime Minimize downtime between batches with our optional single-channel or multi-channel Wash-In-Place (WIP) automatic cleaning system. This fully automated cycle ensures thorough, repeatable, and validatable cleaning, freeing up operator time and getting you ready for the next run faster.

Specifications

| Compressed Air: | 0.4-0.7MPa |

| Draught Fan: | 18.5kw |

| Certification: | CE, ISO |

| Voltage: | 380V |

| Specification: | 3300x2300x2900mm |

| Container Volume: | 22-1500L |

| Capacity: | 5-500 Kg/Batch |

| Equipment Material: | steelstainless steel 304,316 |

| Weight: | 1300KG |

Applications

- Pharmaceutical: Perfect for creating uniform granules for tableting and capsule filling, improving compressibility and dosage uniformity. Widely used for both immediate-release and controlled-release formulations.

- Food & Nutraceutical: Ideal for producing instant drink mixes, soup powders, seasonings, and dietary supplements that require excellent solubility and flow properties.

- Chemical: Efficiently granulates pigments, detergents, fertilizers, and other chemical compounds to improve handling, reduce dust, and ensure consistent product quality.

Machine Details

Drying unit

Nozzle