Grand’s Turnkey Solution for Soft Bag IV Drip Bag Production Lines

How Automatic Cosmetics Filling Machine Streamline Skincare Packaging?

Blister Machines: The Unsung Heroes of Pharmaceutical Primary Packaging?

Introduction

The journey of a drug from lab to patient is complex. Recent research, like a 2023 study in Nature Communications, reveals how even nanoscale interactions[1], such as the "protein corona" forming on lipid nanoparticles, critically affect how therapies are targeted and delivered within the body. This underscores a vital truth: a drug's immediate environment is paramount. This brings us to a crucial, often overlooked, stage: Primary packaging. It’s the first line of defense, the material that directly touches the medicine. So, can a common workhorse, the blister machine, truly handle this critical responsibility in primary packaging pharmaceutical applications?

Let's cut to the chase: Absolutely.

What Exactly is Primary Packaging?

Primary packaging is the material that first envelops the product and holds it. Think of the blister pocket holding a tablet, or a vial containing a liquid. In the primary packaging pharmaceutical world, its role is non-negotiable. It must:

- Protect the drug from contamination (moisture, oxygen, light, microbes).

- Maintain the drug's stability and efficacy.

- Ensure patient safety.

- Provide accurate dosing information.

This isn't just a container; it's an integral part of the drug product itself.

Enter the Blister Machine: A Packaging Powerhouse

A blister machine, or blister packing machine, is a cornerstone of pharmaceutical packaging lines. These machines expertly form cavities (blisters) from a web of formable material, typically plastic. The drug product – tablets, capsules – is then placed into these cavities. Another layer, often Aluminum plastic foil (like lidding foil), is then sealed over the cavities. This whole operation is a sophisticated filling and sealing machine process, creating individual, protected doses.

Why Blister Machines Excel at Primary Packaging

So, what makes a blister machine so effective for Primary packaging?

- Superior Protection: The individually sealed cavities, often made from materials like PVC, PVDC, or Aluminum plastic combinations, offer excellent barriers against environmental factors. This shields sensitive medications from degradation.

- Product Integrity & Tamper Evidence: Each blister unit is sealed. Any tampering is immediately obvious, enhancing patient safety. This integrity is a hallmark of good primary packaging pharmaceutical practices.

- Unit-Dose Precision: Blisters provide pre-portioned, unit doses. This helps patients adhere to prescribed regimens and reduces the risk of dosing errors – a massive win for compliance.

- Versatility: Blister packing machines can handle a wide array of solid dosage forms, from tiny pills to large capsules, making them incredibly versatile.

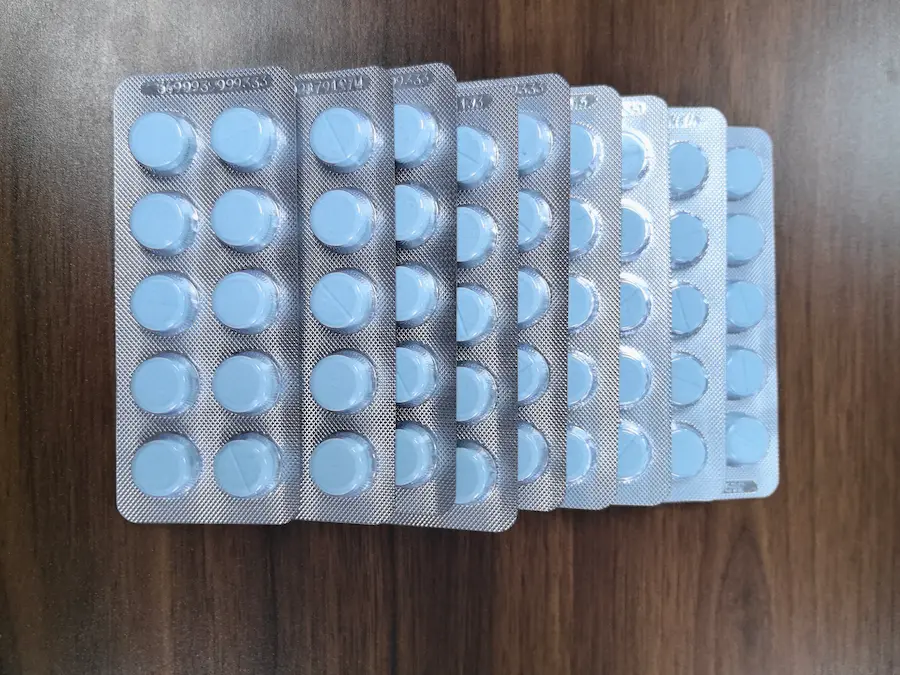

Grand Sample blister filling machine

Key Considerations for Top-Notch Blister Packaging

While blister packaging is a strong contender, achieving optimal Primary packaging requires attention to detail:

- Material Choice: Selecting the right forming films (like PVC, PET, PP) and lidding materials (often Aluminum plastic laminates) is crucial for the required barrier properties and drug compatibility.

- Machine Quality: The precision of the blister machine itself is key. Consistent forming, accurate filling, and robust sealing are non-negotiable. A reliable filling and sealing machine function ensures package integrity.

- Validation & Compliance: Like all pharmaceutical processes, blister packaging operations must be thoroughly validated and comply with Good Manufacturing Practices (GMP).

Blister filling machine key positions

The Bigger Picture: Quality In, Quality Out

Effective Primary packaging doesn't start at the blister machine. It begins with a high-quality drug product. For solid doses, this means well-made tablets. This is where advanced machinery like Grand tablet presses play a vital role. Grand machines are recognized for their high efficiency and precision, offering customizable solutions to meet diverse manufacturing needs.

By ensuring tablets are consistently formed with correct weight, hardness[2], and dimensions , these presses provide the ideal input for the subsequent blister packaging stage. After all, even the best blister packing machine can't fix a poorly made tablet.

The Verdict: Blister Machines are Primary Packaging Champions

So, can a blister machine handle the demands of Primary packaging? The answer is a resounding yes. They are not just capable; they are essential. From protecting delicate formulations with materials like Aluminum plastic to ensuring patient compliance through unit-dose packaging, the blister packing machine is a critical filling and sealing machine that upholds the integrity and efficacy of countless pharmaceutical products. When paired with quality upstream processes, like tablet manufacturing on precise Grand tablet presses , blister packaging stands as a robust solution in the world of primary packaging pharmaceutical.

References

[1].Liu, K., Nilsson, R., Lázaro-Ibáñez, E. et al. Multiomics analysis of naturally efficacious lipid nanoparticle coronas reveals high-density lipoprotein is necessary for their function. Nat Commun 14, 4007 (2023). https://doi.org/10.1038/s41467-023-39768-9

[2].The Hardness of Tablet: Why It Matters in Pharmaceutical Manufacturing.

2 Comments

Great overview! This piece rightly highlights blister machines as vital for pharmaceutical primary packaging. The emphasis on protection, integrity, and unit-dose precision clearly shows their importance. It’s also good to see the connection made to upstream quality, like well-formed tablets from reliable presses, for truly effective packaging.

This article makes a strong case for blister packaging’s role in pharma. It clearly explains how blister machines meet primary packaging demands, from protecting the drug with materials like aluminum-plastic foil to ensuring patient safety and dosing accuracy.