Top Blister Packaging Machine Recommendations in 2025

Strip Pack vs. Alu-Alu Blister — Which is Right for Your Product?

Why the Blister Pack is Pharma’s Most Vital Fortress?

In the world of medicine, trust is everything. A patient places their trust in the belief that the small tablet or capsule they are about to take is safe, pure, and will deliver its intended therapeutic effect. This trust is upheld by a silent, unassuming hero of the pharmaceutical industry: the blister pack. More than just a piece of plastic and foil, this ubiquitous blister package is a marvel of material science and precision engineering—a miniature fortress designed to protect its precious contents from a host of threats.

While bottles have their place, the shift towards blister packaging for solid dosage forms has been definitive, and for good reason. It offers an unparalleled level of protection, integrity, and patient safety. This article will deconstruct this vital technology, exploring the science behind the materials, the advantages it confers, and the advanced blister packaging machinery required to create this essential guardian for modern medicine.

The Anatomy of a Fortress: Deconstructing the Blister Pack

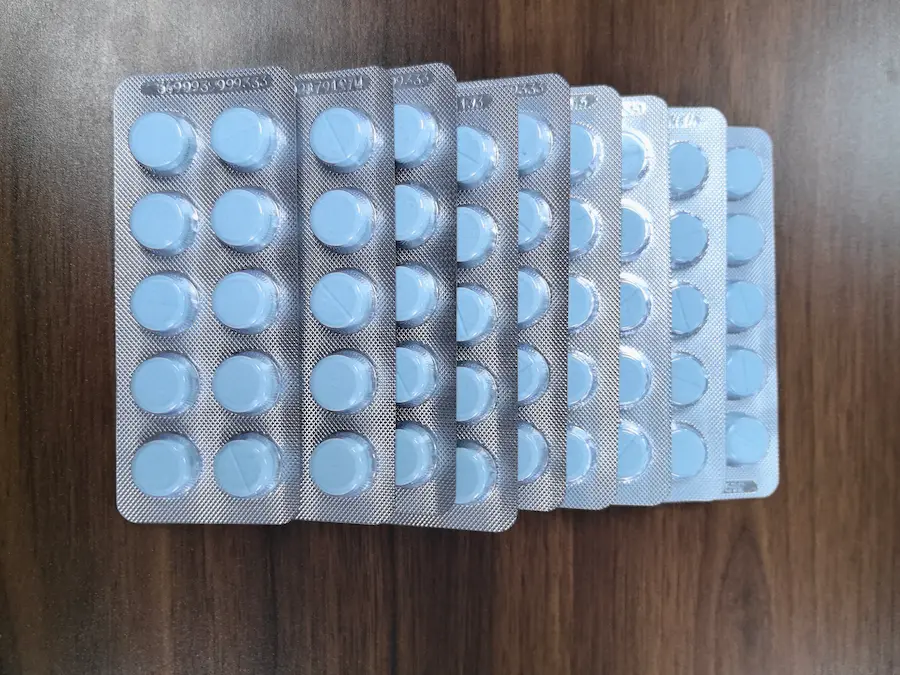

A blister pack appears simple, but its components are chosen with exacting scientific criteria to create a stable micro-environment for the drug.

- The Forming Film (The Cavity Fortress): This is the transparent plastic cavity that houses the product. It is typically created through thermoforming, where a sheet of plastic is heated and drawn into a mold. Common materials include:

- PVC (Polyvinyl Chloride): The workhorse of blister packaging. It’s cost-effective and provides a decent barrier against moisture.

- PVDC (Polyvinylidene Chloride): Often coated onto PVC, PVDC provides a superior barrier to both moisture and oxygen. The choice between PVC and PVDC depends on the drug's sensitivity. A key metric here is the Water Vapor Transmission Rate (WVTR); a lower WVTR means better protection against humidity.

- The Lidding Foil (The Impenetrable Gate): This is the foil backing that seals the product within the cavity. Typically made of hard-toughened aluminum, it provides a nearly perfect barrier. Its Oxygen Transmission Rate (OTR) and WVTR are close to zero, effectively sealing the drug off from the atmosphere. This is critical for preventing oxidation, a common pathway for drug degradation.

- The Ultimate Fortress: Cold Form Foil (Alu-Alu): For highly hygroscopic or light-sensitive drugs, a standard thermoformed blister pack may not be enough. This is where the alu-alu blister pack comes in. In this process, a laminate of aluminum is "cold formed" (i.e., stamped) into the cavity shape. Because it is pure aluminum, it provides an absolute barrier to moisture, oxygen, and light, offering the highest level of protection possible.

The "Why": Four Pillars of Blister Packaging's Superiority

The global adoption of blister packs is built upon four undeniable advantages that directly address the core needs of the pharmaceutical industry.

Pillar 1: Unyielding Product Protection & Stability. The primary function of any pharmaceutical packaging is to protect the drug. The hermetically sealed cavity of a blister pack isolates each dose from the environment, protecting it from moisture, oxygen, light, and microbial contamination. This preserves the chemical and physical integrity of the drug from the factory to the patient, ensuring it remains safe and effective up to its expiration date.

Pillar 2: Guaranteed Dose Integrity & Patient Compliance. Unlike a bottle where all tablets are commingled, each dose in a blister pack is held separately. This has two major patient safety benefits:

- Dose Accuracy: It prevents tablets from breaking or chipping against each other.

- Compliance: The blister card can be printed with days of the week or other markings, providing patients with a clear, visual way to track their intake and adhere to their prescribed regimen. This simple feature has been shown to significantly improve patient compliance.

Pillar 3: Absolute Tamper Evidence. In an age of heightened security concerns, tamper evidence is non-negotiable. A blister pack provides this inherently. To access the product, one must permanently break the foil seal. There is no way to open it and reseal it without leaving obvious, irreversible evidence. This gives patients and healthcare providers confidence that the medication has not been compromised.

Alu Alu vs. Blister Packaging: Choosing the Ultimate Barrier for Your Product

Pillar 4: Enhanced Information and Branding The paperboard backing of a blister card, or the carton it’s placed in, offers valuable real estate. It allows for clear printing of the product name, dosage strength, lot number, and expiration date. This information stays with the individual doses, unlike in a bottle where the outer packaging may be discarded.

The "How": A Look Inside a Modern Blister Packaging Machine

Creating millions of these perfect fortresses requires a sophisticated, high-speed tablet packaging machine. The process, while complex, can be broken down into four key stages executed by a single piece of blister packaging machinery.

- Forming Station: The forming film is unwound and gently heated. It then passes into the forming station where pressurized air pushes it into a cooled mold, forming the precise cavities of the blisterverpackung. For alu-alu blisters, this station uses a stamp to press the foil into shape without heat.

- Filling Station: The newly formed web of cavities moves to the filling station. Here, a dedicated feeder (brush box for tablets, gravity feeder for capsules) accurately deposits a single dose into each cavity. Vision systems can be used here to ensure every cavity is correctly filled.

- Sealing Station: The lidding foil is brought into contact with the filled web. They pass through the blister packaging sealing machine station, where a heated, often knurled, platen applies precise pressure and heat. This bonds the sealant layer of the foil to the forming film, creating a perfect hermetic seal around each cavity.

- Finishing Station: In the final section of the blister pack machine, the sealed web is coded with lot/expiry information. It then passes through perforation and cutting dies that separate the web into the final, individual blister packs or cards, ready for the next stage of packaging.

The Grand Ecosystem: Beyond the Blister Pack

A perfect blister pack is a critical achievement, but the journey to a market-ready product isn't over. This is where Grand's expertise in complete, integrated lines provides a strategic advantage.

The finished blister bag or card flows seamlessly from Grandpack blister machine packing line into a Grand Cartoning Machine. This sophisticated system can automatically feed leaflets, orient the blister cards, and insert them into a product carton before sealing it shut, creating the final capsule filling blister box.

But the automation doesn't stop there. These cartons can then be conveyed to a Grand Case Packer, which groups them and packs them into shipping cases. Finally, a Grand Robotic Palletizer can stack these cases onto a pallet, creating a stable, traceable load ready for distribution. By providing a full-line solution, Grand ensures a seamless, efficient, and reliable process from the raw tablet to the final pallet.

Conclusion: A Commitment to Quality, Sealed in Foil

The blister pack is far more than a simple container. It is a highly engineered system that stands as the last line of defense for a drug's integrity and a patient's safety. Its rise to prominence is a direct result of its superior ability to protect, identify, and secure individual doses of medicine.

Choosing the right materials and, just as importantly, the right blister packaging machinery is a critical decision for any pharmaceutical manufacturer. A high-quality, reliable machine ensures that the theoretical protection of the blister package is perfectly realized, millions of times over. It’s a commitment to quality that is sealed with every pack.

FAQs: About Grand's Capsule Filling & Packaging Lines

- How does a Grand capsule filler ensure capsules are handled gently, making them perfect for transfer to a high-speed blister packaging machine? Grand's capsule filling machines are designed with a focus on gentle handling. We use polished, precisely machined tooling and optimized transfer mechanisms to minimize mechanical stress on the capsules. The ejection process is smooth and controlled, ensuring that filled and locked capsules are delivered perfectly intact and correctly oriented, ready for seamless feeding into a downstream blister pack machine.

- Can a Grand capsule filler be synchronized with a Grand blister machine packing line for continuous operation? Absolutely. This is a core strength of the Grand ecosystem. Our capsule fillers and blister machines are designed to communicate electronically. They can be integrated into a single, continuous line with a unified control system. The blister machine can "call" for capsules from the filler, ensuring the buffer between machines is always optimized. This synchronized operation eliminates bottlenecks and maximizes the efficiency of the entire line.

- We produce combination products with two different capsules. Can Grand provide a solution for filling these for a multi-product blister card? Yes, we can design custom solutions for such applications. This could involve using two separate, synchronized capsule fillers—one for each capsule type—that feed onto a custom-designed transfer system leading to the blister packaging machine. The blister machine would then be programmed to place the different capsules into their designated cavities on the same blister card, providing a complete and automated solution for your combination product needs.

References