The Most Reliable Laboratory Blister Machine | Grand

Liquid capsules replace injections? | Oral liquid capsules | Grand

Your Machine is Ready: Inside Candy Packaging Machine Fast & Safe Shipping Process

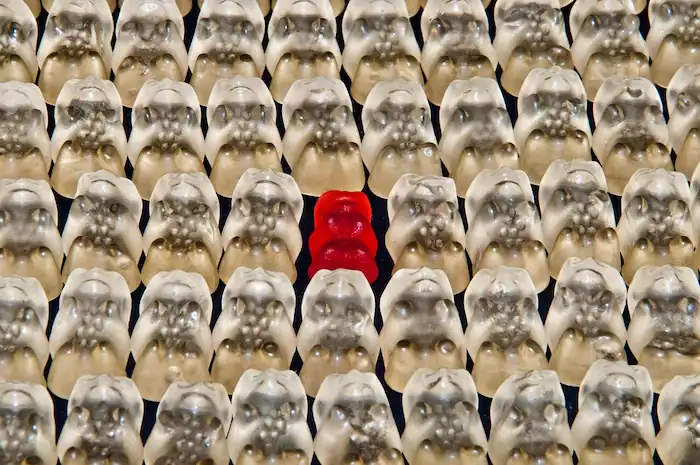

Introduction

You’ve made the decision. You researched the market, you spoke with our engineers, and you placed your order for a new, state-of-the-art candy packaging production line. The machine has been built, tested, and approved.

You just sent the final payment.

This is an exciting moment. It’s also a moment when many customers feel a little anxious. The most common question we get is, "What happens next? How does this massive, precise piece of machinery get from your factory in China to my facility in Europe safely?"

At Grand Machinery, we believe our after-sales service is just as important as the machines we build. Our logistics process is a core part of that service. We have streamlined this process for maximum efficiency and safety.

We promise our clients that once the final balance is received, your machine will be packed, loaded, and dispatched to the port within 7 to 20 working days.

This isn't just a goal; it's our standard procedure.

Let's walk you through the entire process, using the example of this complete candy packaging line shipping to a client in Europe.

Step 1: The Trigger – Final Payment Received

The moment our system confirms your final payment, your project is "green-lit" in our logistics department. This single action triggers a rapid, parallel workflow:

Booking: Our logistics team immediately books your container space on a vessel heading to Europe.

Scheduling: We schedule a "container loading day" at our factory, coordinating the truck and our packing team.

Documentation: We begin preparing all essential export and customs documents.

This immediate action is how we start the clock on our 7-20 day promise. We don't wait. We act.

Step 2: The "Grand" Pack – Custom Wooden Crating

A machine's journey across the ocean is long. It will be moved by crane, truck, and ship. It will face moisture, vibration, and pressure. We protect your investment with expert packing.

We do not use standard-size boxes. We build custom wooden crates for every single component. As you can see in the photos, these are not flimsy boxes; they are robust, reinforced wooden crates built for international shipping.

For a candy packaging line, this means:

The main wrapping machine gets its own crate.

The multi-head weigher and platform get a separate, custom-fit crate.

The feeding conveyors and control cabinets are packed into their own reinforced boxes.

Our technicians carefully disassemble the line into the safest possible shipping modules. Then, our carpentry team builds a crate around each one. We fix the machine securely to the crate's base. This prevents any movement inside the box, protecting delicate sensors and calibrated parts.

Step 3: Loading Day – A Masterclass in Precision

On the scheduled day, the 40-foot container (a 40HQ or 45G, as seen in the images) arrives at our factory. This is where our specialist team takes over.

You can see our forklift driver in action in the photo. He is a highly trained professional who has loaded thousands of machines.

Loading a container is a game of precision. It is not just about speed; it is about balance and safety.

Careful Lifting: Our driver gently lifts each massive crate. He operates the forklift with smooth, deliberate movements. There is no rushing.

Strategic Placement: Our team has a loading plan. They place the heaviest crates first, distributing the weight evenly across the container floor. This is critical for safe transport on the truck and on the vessel.

Perfect Fit: The crates are loaded one by one, fitting perfectly inside the container. You can see in the photo from inside the container how the crates are placed securely.

Step 4: Securing for the Sea – Zero Movement

Once all the crates are inside, the most critical safety step begins: securing the cargo.

A container on a ship in the North Atlantic can experience rough seas. We pack for a worst-case scenario.

Our team enters the container and uses high-tensile strength straps and internal wooden bracing. They anchor the crates to the container's internal lashing points. They brace the crates against each other.

Our goal is zero movement. When your candy packaging line arrives in Europe, it should be in the exact same position it was when it left our factory.

After a final inspection, our staff (as seen in the photo) watch as the heavy container doors are closed and sealed with a high-security bolt seal. We record this seal number for you.

Step 5: Dispatch to Port – The Journey Begins

As you can see in the photos, the international-standard truck is now ready. The container is secure. The paperwork is complete.

The truck driver departs our factory and begins the domestic journey to the sea port (like the Port of Guangzhou or Shenzhen). We handle all the complex procedures at the port. Our team manages the customs declaration and ensures your container is cleared for export and loaded onto the correct vessel.

Step 6: Transparency & Tracking – You Are in Control

Our job is not finished when the truck leaves. For us, after-sales service means complete transparency.

The moment the ship leaves the port, our team will send you a complete set of crucial documents:

Bill of Lading (B/L): The official legal document for your shipment.

Commercial Invoice & Packing List: For your customs clearance.

Certificate of Origin: To help with any import tariffs.

Tracking Information: We provide you with the vessel name and tracking number so you can watch your machine's journey in real-time.

Our Promise: Your Peace of Mind

From the moment you pay your final balance, our team works with speed and precision. The 7-to-20-day dispatch window is our commitment to you.

We built your machine with precision. We pack and ship it with the same level of care. When you buy from Grand Machinery, you are not just buying a piece of equipment. You are buying a complete, reliable, end-to-end service.

Your new candy packaging line is on its way.