What is a Micro Pulverizer Used For?

How a Capsule Filling Machine Works: The Ultimate Guide for Pharma

How a High-Speed table Counting Machines Redefines Production Efficiency?

Introduction

In the complex choreography of a pharmaceutical Tablet packaging production line, every machine must perform in perfect sync. Yet, one stage consistently holds the power to dictate the pace for all others: the counting and filling station. A slow, inaccurate, or unreliable Counting Machine creates an immediate bottleneck, causing upstream and downstream equipment to sit idle and crippling overall output. It’s the chokepoint where efficiency is either won or lost.

But what if this critical stage could be transformed from a bottleneck into the powerful, reliable heartbeat of your entire operation? A modern, high-speed counting machine does exactly that. It’s not merely a device for placing tablets in a bottle; it's the central pacemaker that enables a quantum leap in accuracy, automation, and throughput.

This article will delve into the advanced mechanics and intelligent systems that define a superior counting machine. We’ll explore how this technology directly solves the most common production challenges and how, as part of a fully integrated Tablet production line from a partner like Grand, it becomes the cornerstone of manufacturing excellence.

The Evolution of Accuracy: From Manual Labor to Intelligent Machines

To appreciate the modern counter, it's worth remembering the past. Manual counting by operators was slow, labor-intensive, and fraught with human error and contamination risks. Early mechanical counters improved speed but often struggled with accuracy and product flexibility. Today, two advanced technologies dominate the high-efficiency landscape:

- The Swing Type Counting Machine: This robust design utilizes precisely engineered oscillating plates with holes matched to the tablet size. A gentle, swinging motion guides tablets into the holes, ensuring a set number drops into the bottle with each cycle. The Grand

Swing-type counting machine perfects this method with special oscillating structures for low-noise operation and easy adjustment, making it a highly reliable workhorse. - The Electronic Counting Machine: Representing the cutting edge, this technology replaces mechanical holes with channels equipped with advanced infrared sensors. As tablets or capsules pass through, the electronic eyes count them with lightning speed and incredible accuracy. This method is exceptionally flexible, able to handle virtually any size and shape of solid dosage form—from tablets to capsules and softgels—without the need for part changes.

Regardless of the core technology, a truly elite Counting Machine integrates a suite of features designed to maximize the efficiency of the entire Counting production line.

The Pillars of Efficiency: How a Grand Counting Machine Transforms Your Line

Efficiency isn’t just about raw speed; it’s a holistic measure of speed, accuracy, uptime, and integration. A Grand High-speed counting machine is engineered to excel in all these areas.

1. Intelligent, Self-Regulating Workflow

A standalone machine running at full speed is useless if the rest of the line can’t keep up. Grand counters are designed with intelligent automation to act as the line’s central nervous system.

- Bottle Sensing Logic: Equipped with photoelectric sensors at both the inlet and outlet, the machine operates with "no bottle, no fill" intelligence. It automatically starts counting when it detects a supply of empty bottles and automatically pauses if it senses a downstream backup (e.g., at the capper). This prevents spills, jams, and unnecessary wear, creating a smooth, self-regulating flow.

- Variable Speed Control: The machine’s speed is not fixed. Using advanced frequency converter control technology, operators can precisely adjust the counting and conveying speed to perfectly match the requirements of a specific product or the pace of the entire line. This provides the flexibility needed to create optimized, custom production plans.

2. Uncompromising Accuracy and Product Integrity

In the pharmaceutical industry, an inaccurate count is not just a production error; it's a critical compliance failure. Grand machines are built with multiple safeguards to ensure every bottle has the perfect count.

- Advanced Detection: Whether using electronic sensors or precisely machined counting plates, the system is designed for accuracy.

- Dust Control Systems: Tablet dust is the enemy of accuracy, as it can interfere with sensors. Our machines are designed with integrated dust extraction ports that connect to a dust collector. This keeps the counting channels and sensors clean, ensuring reliable performance and a cleaner cGMP environment.

- Automatic Rejection: The system can be equipped with detection devices to automatically identify and reject containers with a grain shortage or remove broken tablet fragments, ensuring only perfect products proceed.

3. Built for the Realities of cGMP Manufacturing

Compliance and cleanability are non-negotiable. The Grand Counting Machine is designed from the ground up to meet and exceed GMP standards.

- Superior Materials: All parts that come into contact with the product are made from high-quality stainless steel or non-toxic, stable non-metallic materials, finished with a high polish to prevent sticking and contamination.

- Ease of Cleaning: The design emphasizes simple, accessible construction, allowing for easy disassembly and thorough cleaning between batches to prevent cross-contamination.

- Enclosed Design: Many components are housed within a sealed, box-like structure to improve dust control, reduce operational noise, and simplify exterior cleaning.

4. Flexibility for a Multi-Product Environment

Modern pharmaceutical production requires the ability to handle a diverse portfolio of products. A Grand Counting Machine is engineered for rapid and simple changeover. By adjusting the machine head’s tilt angle, the oscillation frequency, and the bottle guide rails, the same machine can be quickly configured to handle different tablet sizes and bottle specifications, drastically reducing downtime between production runs.

Beyond the Count: Grand's Vision for a Complete Tablet Production Line

A high-performance Counting Machine is a powerful asset, but its true potential is unleashed when it is part of a fully integrated Tablet filling production line. At Grand, we specialize in providing these seamless, turnkey solutions.

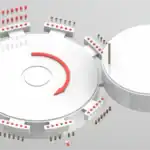

Our vision of a complete Tablet packaging production line ensures a flawless workflow from start to finish:

- HTLP-300 High-Speed Bottle Unscrambler: The line begins by automatically orienting and feeding empty bottles onto the conveyor with precision and care.

- The High-Speed Counting Machine: The heart of the line, our counter (either electronic or swing-type counting machine) accurately fills each bottle at a pace that sets the tempo for the entire operation.

- HTGZ-300 Desiccant Inserter: If required, a desiccant pouch is automatically inserted to protect the product from moisture.

- HTCX-300 High-Speed Capping Machine: Caps are sorted, fed, and precisely torqued onto each bottle, ensuring a secure seal.

- HTFK-300 Electromagnetic Induction Sealer: An aluminum foil liner is hermetically sealed to the bottle rim, providing a tamper-evident barrier.

- HTTB-300 Self-Adhesive Labeling Machine: Finally, a high-speed labeler applies the product label with perfect placement.

By sourcing this entire integrated line from Grand, you eliminate the risks of multi-vendor incompatibility, simplify validation, and ensure every component works in perfect harmony to maximize your overall equipment effectiveness (OEE).

Conclusion: Counting on Efficiency

In the final analysis, a high-speed counting machine is far more than a simple counter. It is the critical engine that drives the efficiency, accuracy, and compliance of your entire bottling operation. Breaking the traditional bottleneck allows every other machine on the line to perform at its peak.

Investing in an advanced, reliable, and intelligent counter from Grand is an investment in your production line’s future. It’s a commitment to quality, a step towards greater automation, and the single most effective way to ensure that your Tablet filling production line operates not just faster, but smarter.

FAQs: About the Grand High-Speed Counting Machine

- What types of products can the Grand Counting Machine handle? Our counting machines are incredibly versatile and designed to handle a wide range of solid dosage forms. This includes all shapes and sizes of tablets (coated, uncoated, round, oval), hard capsules, and softgels. The machine’s settings can be easily adjusted to accommodate the specific dimensions and characteristics of your product, ensuring high accuracy across your entire portfolio.

- How does the machine prevent miscounts from tablet dust, a common issue in production? We address this critical issue with an integrated dust management system. The machine is designed with a dust collection port that connects to an external dust collector. This creates a negative airflow that continuously removes fine dust from the counting area, keeping sensors and counting tracks clean. This ensures that only tablets are counted, leading to superior accuracy and reliable, long-term performance.

- How does the Grand Counting Machine integrate into a complete Tablet filling production line? Our machines are engineered for seamless integration. They feature intelligent photoelectric sensors that communicate with upstream and downstream equipment, automatically starting when bottles are available and pausing when the line is backed up. With variable frequency drives controlling the speed and standardized communication protocols, our

Counting Machine can be perfectly synchronized with Grand's bottle unscramblers, cappers, and labelers to function as a single, cohesive, and highly efficient production line.