Tube Sealing Machine

Semi Auto Capsule Filling Machine CGN-208D2

Automatic Tablet Making Machine ZP420-25/35/37D

The ZP420 double-pressing machines enable automatic rotary compression, variable frequency, and continuous press. ZP420s are made of robust stainless steel and equipped with the non-toxic, smooth, and wear-resistant turntable to maintain stability. Its double-press structure with a pre-pressing guide rail, extending the compression time and ensuring a quieter operation when pressing tough materials. Double discharging hoppers realize the production of two-color tablets with only one step. Additionally, the overload protection device could automatically halt the machine when pressure overload occurs.

Features

- Advanced Motor Control: Equipped with a frequency converter to enable precise motor speed control, facilitating effortless, safe, and accurate speed adjustment.

- Modern Interface: Features a high-speed tablet press with a touch key and screen display. Its stainless steel operation panel remains both functional and aesthetic.

- Efficient Lubrication: The system supplies sufficient ample oil to crucial components, enhancing performance and longevity.

- Easy Maintenance: The transparent and visible working section made of glass and without pillars allows full access for cleaning and maintenance. The top plate of the tablet-pressing room incorporates two embedded lighting lamps for better visibility.

- Enhanced Transmission System: The worm gearbox encloses the transmission system, isolating it from contamination and reducing noise and wear.

- User-Friendly Design: The unique installation structure design facilitates easy maintenance and replacement of the lower punch guide and lower-pressure wheel. It also incorporates a mobile powder vacuum system to enhance the cleaning efficiency.

- Cost-Effective Operation: ZP-type punch dies are economical to obtain and switch

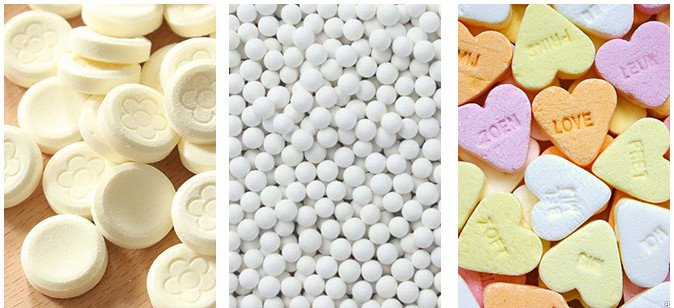

- Versatile Application: The tablet press is extensively utilized in the manufacturing of tablet-shaped prescription medications, chemicals, food, nutritional products, and electronics.

- Stainless Steel Construction with Enhanced Durability: Composed of stainless steel, the machine has a hardened layer coated on the surface, offering enhanced durability to the turret.

- Enclosed Drive Devices: All drive devices are enclosed internally, which is conducive to maintaining cleanliness. Regular weekly cleaning is advisable.

- Auto-Close Safety Feature: The machine is furnished with an auto-close function that activates upon the detection of overpressure, ensuring safe operation.

Specifications

| Model: | ZP25 DEU | ZP35 DEU | ZP37 DEU |

| Max Production Capacity: | 90000pcs/h | 126000pcs/h | 133200pcs/h |

| Max Turret Speed(r/min): | 0-30 | ||

| Max Pressure: | 120Kn | ||

| Max Filling Depth: | 15mm | ||

| Max Tablet Thickness: | 0.5-6mm | ||

| Msx Tablet Diameter: | 18mm | 18mm | 18mm |

| Motor Power: | 5.5KW/380V,50Hz | ||

| Overall Size: | 1250*1000*1650mm | ||

| Machine Weight(kg): | 1850 | ||

Machine Details

Hopper

Designed for efficient material loading, minimizing waste.

Vacuum Cleaner

Keeps the machine clean by removing excess powder.

Tablet Discharge Port

Ensures smooth and consistent tablet output.

Control Panel

User-friendly interface for easy operation and monitoring.

Glass Cover

Provides clear visibility while protecting the internal components.

Surface Smooth Treatment

Enhances durability and makes cleaning effortless.