3 Core equipments of modern Filling Production Line

The Evolution of Traditional Chinese Medicine in Pharmaceutical Packaging

What is an excellent blister packaging line manufacturer?

In the world of pharmaceutical manufacturing, efficiency, precision, and reliability are crucial. This is especially true when it comes to the production of blister packaging lines and other pharmaceutical machinery solutions such as tablet, liquid, capsule, powder, and granule packaging equipment. As a leading manufacturer of blister packaging production line, we provide state-of-the-art machinery solutions designed to meet the most demanding requirements of the pharmaceutical industry. Our Made-in-China solutions offer the perfect blend of high performance, cost-effectiveness, and robust reliability, making us a trusted partner in pharmaceutical packaging solutions.

What is Blister Packaging and Why is it Important?

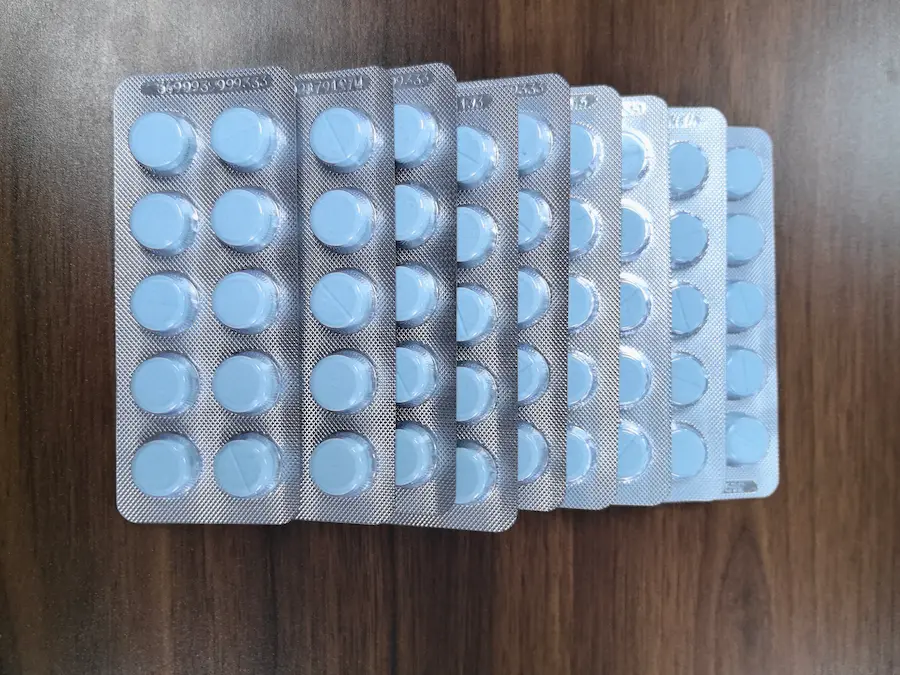

Blister packaging is a widely used method for sealing tablets, capsules, and other pharmaceutical products in a protective layer, typically made of plastic or aluminum. The blister packs are often designed to ensure safety, protect against contamination, and allow easy handling by consumers. This type of packaging ensures the integrity and longevity of pharmaceutical products by providing a barrier to moisture, light, and air, thereby preserving the quality and effectiveness of the product.

The importance of blister packaging in the pharmaceutical industry cannot be overstated. A well-designed blister pack helps prevent product degradation, ensures compliance with regulations, and enhances patient convenience. Additionally, the high level of tamper resistance that blister packaging provides makes it an essential choice for pharmaceutical manufacturers worldwide.

Types of Pharmaceutical Equipment We Offer

We manufacture a diverse range of pharmaceutical machinery designed for different forms of dosage packaging. Our equipment solutions are specifically engineered to handle the following types of pharmaceutical products:

1. Tablet Packaging Machines

Grand tablet blister packaging machines are designed to handle a wide range of tablet sizes and shapes. They are equipped with advanced features to ensure the tablets are accurately placed and securely sealed in the blister pack. The machines are highly customizable to accommodate various packaging requirements, from simple designs to more complex, multi-dose blister packs.

2. Capsule Packaging Machines

Grand capsule blister packaging machines are precision-engineered to ensure the efficient packaging of capsules without damage. With advanced sealing technology, these machines provide high-speed production and ensure that capsules are securely sealed within their individual blisters, preventing contamination or exposure to environmental factors.

3.Liquid Filling and Packaging Machines

For liquid-based pharmaceutical products, our liquid filling and packaging machines provide an ideal solution. These machines are equipped with highly accurate filling systems to ensure precise dosage and packaging of liquids. From syrups to injectable solutions, our equipment guarantees reliable and sterile packaging, preserving the integrity of the liquid products.

4. Powder and Granule Packaging Machines

Our powder and granule packaging machines are designed to handle fine powders and granular substances with ease. These machines feature automated filling, sealing, and labeling functions, ensuring consistent and high-quality packaging for powders and granules. They are ideal for pharmaceutical products such as medicinal powders, supplements, and granules.

Key Features of Our Blister Packaging Production Lines

When it comes to blister packaging production lines, our solutions stand out due to several key features:

1. High Efficiency

Our blister packaging production lines are designed for high throughput and low downtime, which increases overall production efficiency. Whether it’s handling small or large batch sizes, our machines are engineered to deliver consistent results.

2. Precision and Accuracy

The precision of our equipment is second to none. Every blister is securely sealed with pinpoint accuracy, ensuring no defects in the packaging process. This level of precision is critical in pharmaceutical manufacturing, where even the smallest error can lead to product contamination or failure to meet regulatory standards.

3. Easy to Operate

User-friendly interfaces and intuitive controls make our blister packaging production line easy to operate. With automated settings and real-time monitoring systems, operators can quickly adjust settings and maintain optimal performance without the need for specialized training.

4. Customization Options

We understand that each pharmaceutical manufacturer may have unique packaging requirements. That’s why our machines offer customizable features such as blister size, sealing technology, and even multi-layer packaging options. This adaptability ensures our equipment meets the specific needs of each client.

5. Compliance with International Standards

All of our blister packaging machines are manufactured in compliance with international standards and regulations. This ensures that your pharmaceutical products meet the necessary quality and safety standards required by health authorities worldwide.

Advantages of Choosing Made-in-China Pharmaceutical Equipment

The advantages of choosing Made-in-China pharmaceutical machinery for your packaging needs are numerous. Our blister packaging production lines provide exceptional value for money without compromising on quality. The manufacturing processes in China are recognized for their cutting-edge technologies, cost-efficiency, and scalability. We combine the best of innovation and affordability, offering you the perfect solution for your pharmaceutical packaging needs.

Additionally, Chinese manufacturers are known for their advanced production techniques, ensuring that all equipment is built to last. Our machines are designed with the latest technological advancements to ensure they meet the evolving needs of the pharmaceutical industry.

Why Invest in Blister Packaging Production Lines?

Investing in a high-quality blister packaging production line comes with several key benefits:

1. Cost Reduction

By automating the packaging process, pharmaceutical manufacturers can reduce labor costs and improve productivity. Our packaging lines are designed to operate efficiently, offering significant cost savings over traditional manual packaging methods.

2. Enhanced Product Safety

Blister packs provide a higher level of safety and protection for pharmaceutical products compared to other packaging types. The airtight seal ensures that products remain free from contaminants and environmental factors, protecting their efficacy and quality.

3. Consumer Convenience

Blister packaging offers significant benefits for consumers, such as easy-to-open packs, dose management, and portability. This can lead to increased patient compliance and satisfaction, particularly for elderly or vulnerable populations.

4. Regulatory Compliance

Our blister packaging production lines are built to meet the stringent requirements set by pharmaceutical regulatory authorities around the world, including the FDA, EMA, and other local health agencies. This ensures that your packaging meets the necessary guidelines for product safety and quality.

Conclusion: Choose the Best Pharmaceutical Equipment Manufacturer

For pharmaceutical manufacturers looking to improve their packaging processes, choosing the right equipment is crucial. With our high-quality blister packaging production lines, you can be assured of increased efficiency, precision, and compliance. Our Made-in-China machinery solutions are designed to meet the diverse needs of the pharmaceutical industry, offering customizable options, reliability, and cost-effective solutions for manufacturers worldwide.