Blister Type: What Can the Grand Blister Machine Produce?

Which Granulator is Used in Wet Granulation?

Grand Fluid Bed Dryer for Importers and Procurement Teams

Looking to upgrade your powder processing line? You’ve probably heard the buzz about fluid bed dryers – those tall stainless-steel towers that make powders dance in mid-air while heat wicks away moisture. In fact, pharmaceutical research calls fluidized bed drying “the method of choice” for wet granules, thanks to its rapid heat/mass transfer, high capacity and relatively low cost[1].

It’s no wonder MDPI researchers note that the fluid bed dryer is “a common piece of equipment widely used in the pharmaceutical industry”[2]. These machines don’t just dry – they often mix and granulate too, turning messy powders into uniform granules. For procurement pros, that means one machine can replace several steps, saving space and time.

Grand Fluid Bed Dryer for Importers and Procurement

Key Features of Grand Fluid Bed Dryers

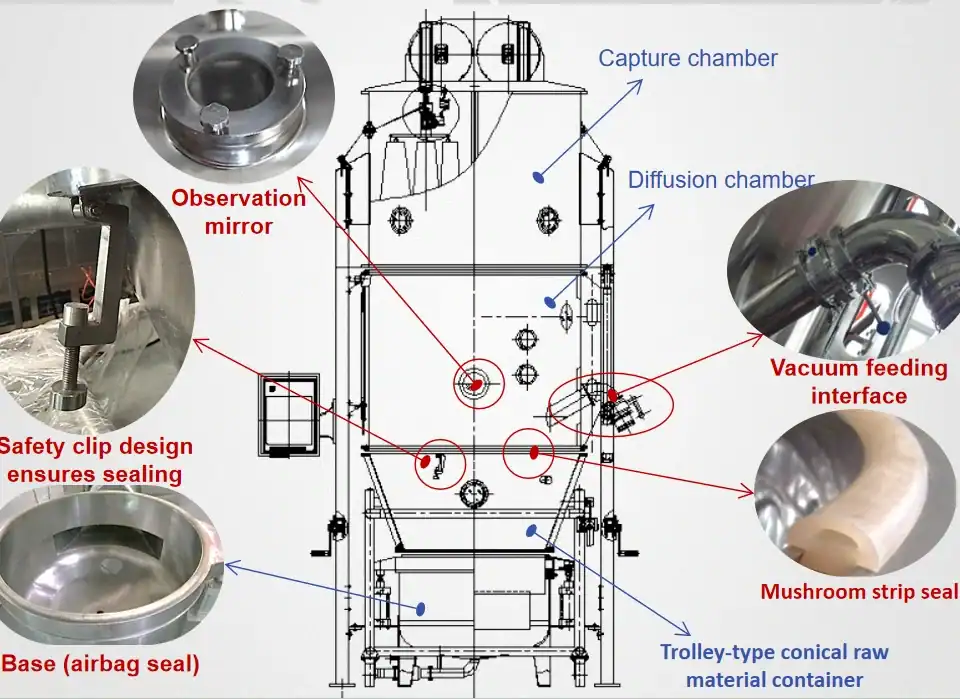

When vetting equipment, technical specs and build quality matter. Grand’s FG-Series offers:

Wide capacity range – Models FG-15 through FG-500 cover lab to full-scale production. For example, an FG-15 unit holds about 45 L (~15 kg of material) per batch, while the largest FG-500 holds 1500 L (~500 kg). Smaller models fit R&D labs; larger ones run your entire granulation line.

GMP-grade construction – All product-contact parts are premium stainless steel with mirror-polished surfaces. The vessel is fully sealed (air-tight) to prevent powder leaks during feeding and discharge. In short: clean design, easy CIP cleaning, and built to FDA/EMA standards.

Advanced controls – Each dryer uses PLC or touchscreen controls for precise batch programming. (Some units even offer SCADA integration.) Temperature, air flow, and spray nozzles (if used) can be set and monitored digitally for reproducibility.

Multi-function granulation – Want one machine to do granulating and drying? Grand’s fluid bed granulators (a.k.a. fluidized bed granulator or fluid bed granulator) add spray atomization and high-shear mixing heads. This means wet granulation and drying happen in one step – a true “all-in-one” pharmaceutical granulator. It’s ideal for producers seeking to streamline wet granulation processes.

Safety and Compliance – Grand’s equipment is ISO 9001 certified and CE marked. They meet explosion-proof and GMP requirements (e.g. spark detection, N2 inerting options) so they’re safe for solvents or dusts.

The FG-Series Fluid Bed Dryer from Grand Machinery. These stainless-steel units handle everything from mixing to spray granulation in an airtight, GMP-compliant design. Each model is built for heavy-duty industrial use – think 24/7 pharma plant operation.

FG-Series Fluid Bed Dryer from Grand

Performance and Applications

Fluid bed dryers shine in many scenarios. By fluidizing powders, they ensure uniform drying and granulation without hotspots. Key points include:

Efficient Drying – Hot air passes through the bed, fluidizing the particles. This rapid mixing means moisture is removed evenly and quickly, shortening cycle times. As one study notes, fluid bed drying achieves “rapid heat and mass transfer” which speeds up production.

Gentle Granulation – Because particles are suspended, you avoid hard compaction. This yields free-flowing granules ideal for tablets or capsules. You also minimize fines (dust) and reduce attrition losses. Many pharmaceutical processors prefer fluid beds for wet granulation and immediate drying in one closed system.

Scalable Processing – Small and large batches behave similarly. In practice, your technician can use FG-15 units for trials and easily scale up to FG-200 or FG-300 with the same settings. This helps with process validation and consistent product quality across scales.

Versatile Uses – These dryers aren’t just for pills. Chemical plants use them for catalyst powders, pigments and specialty resins. Food companies use fluid beds for spices, flavors and instant drinks. In any granulator pharmaceutical context – or chemical/pharma powder processing – a Grand fluid bed dryer is a workhorse.

Grand offers custom solutions too: spray chilled air for cooling, dust collectors for fines, and even integrated pneumatic loading conveyors for automation. The flexibility means importers can specify exactly what their plants need (jet dryer, top-spray granulator, bottom-spray, etc.).

Grand-factory-Fluid Bed Dryer

Procurement Checklist: Why Importers Trust Grand

For procurement teams, choice of supplier is as important as specs. Grand Machinery checks many boxes:

Established Manufacturer – Over 5,000 m² of production space and 85+ staff (R&D, quality, sales) indicate scale. Grand has a long track record (since 1999) in solid dose equipment. They’re experienced in global exports and familiar with import regulations.

Quality Assurance – ISO 9001 and CE certifications mean the equipment meets international quality and safety standards. This simplifies regulatory audits for your end customer.

Warranty & Support – Grand provides a one-year warranty on new machines and lifetime spare-part support. Their engineers are available for remote troubleshooting or on-site help. For an importer, that means a safety net in the rare event of issues.

Fast Delivery – Production lead times are competitive (typically 15–30 days), and they even stock smaller units for quick shipment. This helps project timelines stay on track.

Flexible Commercial Terms – Grand accepts common payment methods (T/T, L/C, PayPal, Western Union, credit cards). They also welcome both end-user orders and distributors. As one FAQ notes, “End users and agents are both welcome,” making bulk purchases or partnerships easier.

Packaging & Logistics – Each fluid bed dryer is packed on a sturdy skid or crate, often with weather-resistant covers. Machines ship worldwide by sea; many importers report safe delivery with proper handling. (Grand’s export experience means they know how to pack heavy vessels for transit.)

Grand FG-Series fluid bed dryers in the assembly area. Each system is customized and assembled under strict QC. Importers will recognize the organized factory setup – large stainless vessels, ducting and control cabinets lined up – as a sign of consistent manufacturing.

Grand Fluid Bed Dryer-Laboratory Equipment

References

[1].Briens L, Bojarra M. Monitoring fluidized bed drying of pharmaceutical granules. AAPS PharmSciTech. 2010 Dec;11(4):1612-8. doi: 10.1208/s12249-010-9538-1. PMID: 21061102; PMCID: PMC3011080.

[2].Barriga, R.; Romero, M.; Hassan, H.; Nettleton, D.F. Energy Consumption Optimization of a Fluid Bed Dryer in Pharmaceutical Manufacturing Using EDA (Exploratory Data Analysis). Sensors 2023, 23, 3994. https://doi.org/10.3390/s23083994