Grand GZPK-26 Rotary Tablet Press: High-Speed Smart Production

Capsule Filling Machine Export Trends 2026 | Global Capsule Machine

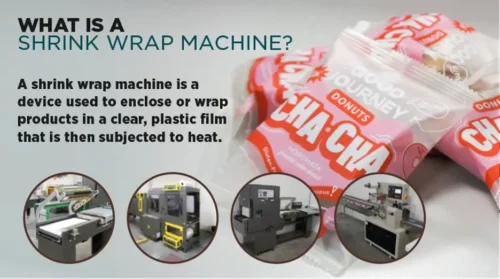

The Expert’s Guide to Shrink Wrap Machines

Category: Packaging machinery | Reading Time: 11 mins

In the world of packaging, presentation and protection are two sides of the same coin. A shrink wrap machine is the bridge between the two. At its core, this device wraps products in a clear plastic film and applies heat, causing the film to shrink tightly around the item to create a form-fitting barrier.

While the concept is simple—sealing the film edges and passing the package through a heat tunnel —the application is where the nuance lies. Whether you are securing pharmaceuticals against tampering or bundling heavy beverages for transport, shrink wrapping offers a fast, versatile solution to keep products safe from dust, moisture, and damage.

Industry Applications: Why Leaders Choose Shrink Wrap

BMD-800 Heat Shrink Machine - GRAND

Shrink wrapping isn't just about making things look shiny; it’s about supply chain integrity. Here is how major industries utilize this technology:

- Pharmaceuticals (Safety First): In pharma, trust is the currency. Shrink wrapping provides secure, tamper-evident seals that are essential for regulatory compliance. It ensures product safety by creating a sterile, protective cover over pill bottles and cartons.

- Food & Beverage (Freshness & Logistics): Manufacturers use shrink wrapping to create airtight seals that protect baked goods and meats from moisture and contaminants. In the beverage sector, shrink systems are crucial for logistics; they are used to bundle all types of containers, including glass and plastic bottles, often replacing bulky cardboard.

Cosmetics (Shelf Appeal): For high-end perfumes and skincare, aesthetics matter. Shrink wrapping delivers a clear, professional wrap that enhances shelf appeal while protecting delicate boxes from dust and scratches.

Industrial & Marine (Heavy Duty): Shrink wrapping scales up massively. For example, using durable 7-mil shrink wrap allows owners to wrap boats and JetSkis, creating a watertight barrier for winter storage.

💡 Expert Insight from Bruce (GrandPack Specialist): "Many clients forget that shrink wrapping isn't just for single items. In the beverage and food sectors, we see a massive shift toward multipacking. Bundling three or four units together using a strong polyolefin film not only increases your average order value but significantly cuts down on shipping waste compared to using master cartons."

Choosing Your Level of Automation

Selecting the right machine depends entirely on your daily throughput requirements.

Manual Machines: Ideal for startups or boutique operations. These require an operator to place the film and use a heat source. They are cost-effective but labor-intensive.

Shrink oven

Semi-Automatic Machines: The "sweet spot" for growing businesses. An operator arranges the product, but the machine takes over the sealing and shrinking. This balance improves speed without the cost of full automation.

upper roll film

Fully Automatic Machines: Designed for large-scale production, these systems handle the entire process—wrapping, sealing, and conveying through the tunnel—without human intervention. They are capable of achieving high throughput, often processing dozens of packs per minute.

Shrink Wrap vs. Other Pharmaceutical Packaging

A common question we face at GrandPack is how shrink wrapping compares to traditional methods like blister packs. While blister packs are excellent for unit-dosing, shrink wrap offers unique advantages for secondary packaging:

- Superior Fit: Unlike rigid blister shells, shrink wrap creates a "tighter fit" that creates a continuous, enclosed package around the product.

- Flexibility: Shrink film conforms to any shape without the need for expensive, custom-made molds.

- Integrity: It is widely accepted in the industry because it maintains product integrity and provides that all-important clear tamper-evident seal.

- Complementary Use: Often, shrink wrap is used over cartons or bunches of blister cards, providing a firm, protective cover that safeguards the primary packaging during transit.

The GrandPack Advantage: Industrial Reliability

When you are running a production line, downtime is the enemy. This is where GrandPack distinguishes itself. We don't just assemble machines; we engineer reliability.

GrandPack’s heat shrink machine is an ISO 9001 certified manufacturer that builds machines using industrial-grade components designed specifically for low failure rates and long operational life.

Why GrandPack Stands Out:

Precision Control: Our machines utilize PID controls for temperature and conveyor speed, ensuring that a delicate cosmetic box doesn't get overheated, and a heavy beverage pack gets enough heat to seal tight.

Hygiene Ready: With stainless steel frames, our systems meet the rigorous hygiene standards required for pharmaceutical and food environments.

Ease of Use: We combine the simplicity of operation with high-speed capability.

💡 Expert Insight from Bruce (GrandPack Specialist): "The biggest mistake I see buyers make is underestimating their need for 'changeover' speed. If you run five different box sizes a day, you don't want a machine that takes 45 minutes to adjust. GrandPack machines are designed with quick-clamp systems and intuitive HMI panels so your operators can switch product sizes in minutes, not hours."