What drives Scientific and Medical Equipment innovation?

Top 11 Tube Filling Machine Manufacturers in the World(2025)

Launching a Gummy Bears with the SE-300 Gummy Production Line

Introduction

Recent studies highlight exciting advances in gummy candy formulation and production. For example, a 2024 Heliyon study enriched gummy recipes with plant extracts and sugar substitutes, creating antioxidant-rich, reduced-sugar gummies[1]. In parallel, confectionery scientists have investigated how ingredient ratios and processing parameters affect gummy texture and shelf life[2]. Such research underscores how gummy candies (think popular gummy bears) can evolve into healthier, high-quality products. These trends offer a real opportunity for entrepreneurs to break into a booming candy market.

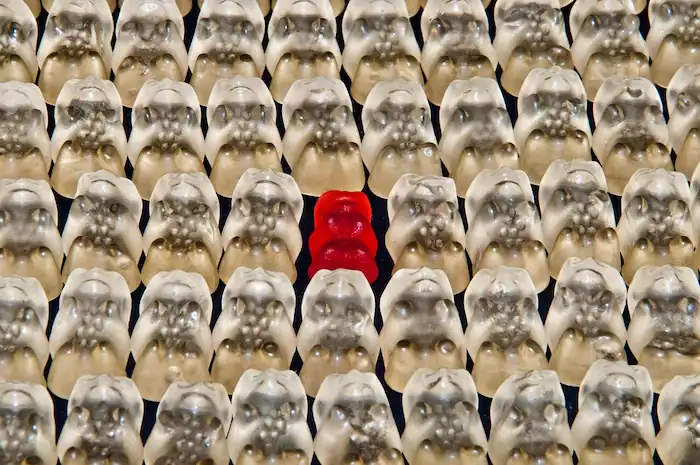

Soft candy has rich colors, diverse appearances and wide applicability

Rising demand: The global confectionery market was about $298 billion in 2021, with soft candies (including gummy bears) especially popular. In fact, gummy candy alone held roughly a $21.4 billion global market in 2022. Industry analysts forecast continued growth: Future Market Insights projects the jellies and gummies segment to expand at about 5.4% CAGR through 2035. North America and Europe currently lead consumption, but emerging regions (Asia-Pacific, Latin America) are showing strong growth. This expanding market is driven by busy lifestyles – consumers love the convenience and fun variety of gummy snacks.

Consumers today expect gummies to deliver more than just sweetness. Health-conscious trends are pushing innovation. Market reports note a shift toward sugar-free and vegan gummies, as well as functional gummies fortified with vitamins, minerals or botanicals. At the same time, there’s rising demand for natural ingredients: organic sweeteners, real fruit flavors and plant-based colorants are replacing artificial additives. Meanwhile, novelty still sells – companies are experimenting with exotic fruit flavors, sour coatings, unique candy shapes and multi-colored combinations to grab attention. In short, gummy candy innovation is transforming candy aisles.

Key steps to launch your gummy brand:

Market & Concept: Identify target customers and market niche (e.g. vegan gummies, vitamin gummies, classic bears).

Recipe & Prototyping: Develop and test gummy formulations (gelatin or vegan base, sweeteners, flavors, inclusions).

Production Setup: Select equipment. Tabletop gummy machines suit R&D, but growing brands benefit from a full production line. The GrandGummy SE-300, for instance, is a turnkey gummy candy line (a “gummy machine”) that automates the entire process.

Branding & Packaging: Create a strong brand story, design labels, and choose safe, appealing packaging materials.

Quality & Launch: Ensure sanitation protocols and food-safety compliance, then roll out sales through retail, online, or wholesale channels.

Grand Soft candy production line-grandpack

Grand Gummy SE-300 Gummy Production Line

The Grand Gummy SE-300 is an all-in-one solution for modern gummy manufacturing. This highly automated production line integrates cooking, mixing, depositing, molding, demolding and cooling in one streamlined process. Its PLC touch-screen control system and servo-driven depositor ensure precise, repeatable operation with minimal manual labor. Ingredients are automatically weighed, cooked and pumped, then filled into starch or silicone molds. With these features, the SE-300 can produce tens of thousands of gummies per hour, allowing your brand to scale up quickly while maintaining consistent quality.

Soft candy production line mold

High Automation and Efficiency

The SE-300 is built for full automation. Its PLC controls and servo motors allow unattended runs, so operators simply set recipes and press start. Ingredient handling (weighing and mixing) and deposition into molds are all managed by the machine. This high level of automation greatly reduces labor costs and human error. In practice, even complex multi-color gummy recipes can be produced efficiently. For example, advanced systems often include auto-dosing for acids, flavors or colors and quick-error alarms. By streamlining every step, the SE-300 boosts throughput and lets manufacturers meet large orders without bottlenecks.

Versatile, Multi-Shape Production

Flexibility is another strength of the SE-300. It supports a variety of gummy shapes and sizes by swapping molds, so you’re not limited to one gummy style. You could make bears one day, worms the next, or even custom brand-specific shapes simply by changing the deposition molds. Some configurations allow dual-hopper systems, enabling two-color or dual-flavor gummies in a single pass. This versatility keeps production lines agile: you can quickly launch seasonal or limited-edition gummies alongside your core products. In short, the SE-300’s multi-shape capability lets you innovate without needing separate machines for each candy design.

Hygiene and Food Safety

Food-grade construction is built in. All SE-300 contact parts and framework use 304 stainless steel – the industry standard for food processing equipment. This material is highly corrosion-resistant, non-toxic and easy to sanitize. The machine features sanitary welds, smooth surfaces and quick-release parts so that cleaning is straightforward. In practice, that means after production you can perform thorough washdowns to eliminate allergen or residue buildup. These hygienic design choices help manufacturers meet strict food safety regulations and ensure the final gummy bears are safe and pure.

Energy Efficiency and Sustainability

Modern candy makers know efficiency matters. The SE-300 incorporates energy-saving features common in next-gen equipment. For example, it may use intelligent heating/cooling controls and insulated kettles to reduce power use. By precisely controlling temperature and cycle times, it minimizes wasted energy during cooking and depositing. Efficient motors and vacuum systems also lower electricity demand. These measures cut operating costs and shrink your carbon footprint. As industry trends show, energy-efficient manufacturing is key to sustainable growth – and the SE-300 is engineered with that in mind.

In summary, the gummy market is thriving with consumer demand for innovative treats. The Grand Gummy Production Line offers a turnkey path for entrepreneurs and candy manufacturers to capitalize on this trend. Its full automation, versatile molding, hygienic design and energy-smart operation make it ideal for launching or scaling a gummy bears brand. By choosing the SE-300 gummy machine, you can ensure high productivity, consistent quality and a safe manufacturing environment.

Ready to start your gummy journey? Contact Grand Gummy today to explore the SE-300 and discover how our advanced production solutions can help bring your gummy candy vision to life.

References

[1].Formulation of functional gummy candies containing natural antioxidants and stevia2024 May 22;10(11):e31581.doi: 10.1016/j.heliyon.2024.e31581. eCollection 2024 Jun 15.

[2].American Institute of Physics. "The physics of gummy candy." ScienceDaily. ScienceDaily, 16 May 2023. <www.sciencedaily.com

[3].Tarahi M, Tahmouzi S, Kianiani MR, Ezzati S, Hedayati S, Niakousari M. Current Innovations in the Development of Functional Gummy Candies. Foods. 2023 Dec 25;13(1):76. doi: 10.3390/foods13010076. PMID: 38201104; PMCID: PMC10778822.

[4].Global Jellies and Gummies Market Poised for 5.4% CAGR Growth, Projected at USD 12.6 Billion by 2035.