Automation in Gelatin Capsule Manufacturing is Becoming Mainstream

Chinese Medicine Soft Gelatin Capsules – In-Depth Analysis

Innovative Soft Gelatin Capsules: The Future of Delivery

Summary

The pharmaceutical and nutraceutical industries are in constant evolution. Consumers demand high-quality products that are safe, effective, and easy to ingest. In recent years, soft gelatin capsules have captured market attention. These innovative dosage forms are more than just a trend. They represent a sophisticated way of delivering active pharmaceutical ingredients. Advances in production have even revolutionized how formulations are developed for nutritional tonics and other therapeutic applications.

Safe, effective and easy-to-take soft capsule products are widely in demand in the market

The Role of Gelatin in Soft Gel Capsules

Why Gelatin Is Essential

Manufacturers blend science with cutting-edge engineering to create top-notch soft gel capsules. A key to this success is selecting high-quality gelatin. Derived from collagen, gelatin has unique properties—film forming ability, thermo-reversibility, and rapid absorption—that make it ideal for gelatin softgel capsules. The chosen gelatin must be fully soluble while offering excellent mechanical strength. This balance ensures that each capsule is robust enough to endure production yet gentle enough for effective body absorption.

The Science Behind Gelatin Selection

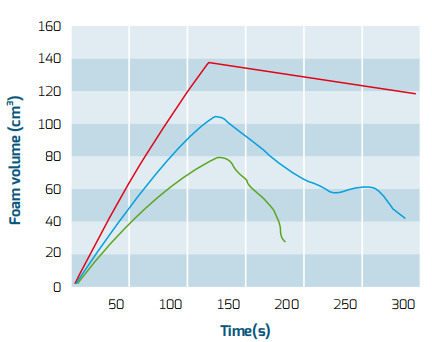

The journey to an optimal soft gel product is complex. Formulation scientists must adjust processing parameters precisely. They work to achieve a gel mass with minimal foaming and consistent quality. Research has shown that characteristics like the molecular weight distribution of gelatin affect its crosslinking behavior. Extensive crosslinking may cause the capsule shell to become tough and insoluble. Industry studies indicate that using gelatin with balanced viscosity is essential for smooth ribbon formation and proper sealing. When the gelatin displays the ideal visco-elastic behavior, the outcome is defect-free soft gel capsules that deliver active ingredients efficiently.

Grand highly automated soft gelatin capsule making machine ensures quality

Overcoming Manufacturing Challenges

Production Process and Equipment

The capsule manufacturing process begins with creating a gel mass that displays uniform quality. Manufacturers must carefully control the process to minimize foaming, which can lead to defects such as leakage or misshapen capsules. Maintaining strict control over temperature and conditions during film formation is key. Studies have demonstrated that even small variations can cause issues like stickiness or inadequate drying, which impact the shelf life of the final product.

The Importance of Drying and Sealing

Proper drying is critical. Excess moisture—levels above 11%—can lead to adhesion or leakage issues. Controlling drying parameters such as temperature, humidity, and air flow is vital to ensure each capsule maintains its structure during storage and use. This is particularly important for formulations like tonics where precise API delivery is critical.

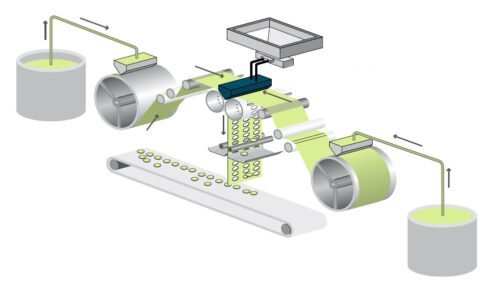

Principle

A soft gel encapsulation machine operates on a principle known as the rotary die encapsulation process. This highly precise and continuous method is designed to form, fill, and hermetically seal soft gelatin capsules in a single, integrated operation. The entire process can be broken down into three fundamental stages: gelatin ribbon preparation, encapsulation, and capsule finishing.

First, the shell material is prepared. This involves creating a warm, liquid gelatin mass, often called the "gel mass," by mixing gelatin, a plasticizer like glycerin, and purified water in a heated tank. This molten mass is then gravity-fed into two separate "spreader boxes." These boxes precisely cast the liquid gelatin onto two large, rotating, chilled drums. As the drums turn, the gel mass cools and solidifies into two continuous, thin, and flexible sheets known as gelatin ribbons. The thickness of these ribbons is meticulously controlled, as it determines the final wall thickness of the capsule.

The two gelatin ribbons are then guided from opposite sides into the heart of the machine: a set of two counter-rotating die rolls. These precision-engineered dies have numerous capsule-shaped pockets machined into their surfaces. As the ribbons converge between the rotating dies, they are pulled into the pockets. Simultaneously, a heated component called an injection wedge, positioned between the die rolls, injects a precise, measured volume of the liquid or semi-solid fill material (such as vitamin oils or medication) directly into the forming capsule. As the die rolls continue their rotation, they press the two sides of the ribbon together, sealing the seams and cutting the filled capsule from the gelatin web.

Finally, the newly formed, very soft capsules drop onto a conveyor belt and are transferred to large tumbler dryers. Inside these dryers, the capsules are gently tumbled in a stream of temperature- and humidity-controlled air. This crucial drying phase removes excess moisture from the gelatin shell, causing it to shrink, harden, and achieve its final, stable form. The leftover gelatin web from which the capsules were cut is collected and can often be recycled.

Advanced Production Through Automation

Integrating Automation in Production

Automation plays a key role in achieving consistent quality while reducing manual intervention. Modern systems, such as the soft capsules machine, integrate various processes from gel mass formation and film forming to final sealing. Automated production lines not only reduce variability but also cut production cycles and lower costs. This integration meets stringent cGMP requirements and provides the precision necessary for high-performance soft gelatin capsules.

Comparative analysis of foam capacity and foam stability of different

gelatin types. (R&D Lab, January 2016).

Benefits of Automated Systems

Automated production offers several advantages:

Enhanced Efficiency: High-speed mixers, film formers, and dryers work seamlessly, reducing cycle times.

Consistent Quality: Automated systems ensure uniform exposure to processing conditions for every capsule.

Reduced Risk of Defects: Precision control minimizes the risk of errors such as leakage or brittle capsules.

Cost Savings: Fewer manual interventions lead to lower labor costs and higher production yields.

Grand’s Leadership in Soft Gel Capsule Manufacturing

Industry-Leading Technology

Among the modern innovations, Grand’s soft capsule manufacturing machine stands out as a leader. Grand has earned its reputation by delivering high-performance automated systems that maintain consistent capsule quality. Their equipment is engineered for efficiency and ease of maintenance, ensuring smooth production runs with minimal downtime.

Why Grand’s Equipment Excels

Grand’s machines feature advanced sensors and control systems that manage every step—from gel mass preparation to final sealing. This leads to:

Stable Production Lines: Consistent conditions ensure each soft gelatin capsule meets quality standards.

Flexibility: The equipment adapts quickly to different capsule sizes and formulations, whether for delayed release, chewable designs, or tonics.

Lower Production Costs: Automation reduces waste and rework, saving companies money over time.

Optimizing Formulations for Superior Soft Gel Capsules

Tailoring Gelatin Properties

Formulation development isn’t one-size-fits-all. The selection of a specific gelatin type is crucial for designing capsules that release the active pharmaceutical ingredient (API) effectively. Optimized gelatin must exhibit proper film forming, minimal foaming, and stable viscosity. Research from industry studies highlights how proper control of these properties can reduce leakage rates significantly—sometimes from 2% to nearly 0% under optimal conditions.

Balancing Formulation and Function

Every capsule's performance is dependent on both its formulation and the manufacturing process. Manufacturers must monitor factors such as:

Gel Mass Preparation: Ensuring a uniform composition without excess foaming.

Ribbon Formation: Maintaining the correct thickness and consistency for perfect sealing.

Final Moisture Control: Achieving an optimal moisture level that prevents stickiness and preserves shelf life.

These elements collectively ensure that the soft capsule functions correctly, delivering APIs safely and efficiently.

The Impact of Soft Gel Capsules on API Delivery

Enhancing Bioavailability

The design and integrity of soft gel capsules directly influence the bioavailability of the active ingredients. The capsule shell must protect the API during storage but release it effectively upon ingestion. In nutraceutical products, for example, a well-designed soft capsule can turn an ordinary tonic into a potent health enhancer.

Meeting Consumer Expectations

Today’s consumers demand products that are innovative and reliable. Soft gel capsules provide an attractive solution that combines aesthetic appeal with superior functionality. The shells are easy to swallow and ensure that every dose remains consistent. This creates a better consumer experience and builds trust in the product’s effectiveness.

Future Trends in Soft Gel Capsule Development

Innovation and New Formulations

The soft gelatin capsule market is evolving. With an increasing number of APIs and the need for specialized delivery systems, CDMOs (Contract Development and Manufacturing Organizations) are continually exploring new formulations. Whether it’s developing delayed-release capsules, chewable designs, or cost-effective tonics, the key lies in advanced formulation science paired with robust manufacturing technology.

Embracing Technological Advances

Automation and digital control systems will continue to shape the future of soft gel capsule manufacturing. Advances in sensor technology, process analytics, and real-time data monitoring will offer even greater precision. This continuous evolution will drive the market forward, ensuring that soft gelatin capsules remain at the forefront of therapeutic delivery technologies.

Conclusion

The path to producing top-quality soft gelatin capsules involves a delicate balance of formulation expertise and advanced manufacturing technology. Selecting the right type of gelatin ensures each capsule forms a perfect film, seals reliably, and securely contains its API. Automated systems—especially those using industry-leading equipment like Grand’s soft capsule manufacturing machine—set the stage for consistent quality and improved production speed.

As the industry embraces innovation, manufacturers are optimizing every step of the process from gel mass preparation to final sealing. The result is a product that not only meets stringent regulatory standards but also enhances API delivery. This progress ensures that consumers receive reliable, high-performance products, whether it’s a potent therapeutic tonic or a nutraceutical supplement. In short, the future of soft gel production is bright, driven by scientific insights, automation, and the continuous pursuit of excellence.

References

[1].Zhong-Li Wang et al.Gelatin-derived sustainable carbon-based functional materials for energy conversion and storage with controllability of structure and component.Sci. Adv.1,e1400035(2015).DOI:10.1126/sciadv.1400035