How is the ampoule sealing achieved?

Your Machine is Ready: Inside Candy Packaging Machine Fast & Safe Shipping Process

The Most Reliable Laboratory Blister Machine | Grand

Introduction

In the world of pharmaceutical research and development, precision is not just a goal—it is a necessity. Every stage, from formulation to clinical trials, demands accuracy, consistency, and a sterile environment. Packaging is the final, critical step in protecting a drug’s integrity.

For small-scale runs, R&D labs, and hospital pharmacies, large industrial packaging lines are often impractical and wasteful. This is where a dedicated blister-packing machine becomes essential. The Grand Laboratory Blister Machine is engineered to fill this gap, offering unmatched reliability, versatility and efficiency for R&D and small-batch production.

The Challenge: Bridging the Gap in Small-Scale Pharmaceutical Packaging

Developing a new drug product often involves dozens of trials. Scientists must test different formulations, undertake stability studies and prepare samples for clinical testing. These efforts require small batches of perfectly packaged products that still meet strict GMP (Good Manufacturing Practice) standards.

Using full-scale production equipment for this kind of work presents several problems:

High cost: Running large machines for just a few hundred samples is not cost-effective.

Material waste: The setup and calibration of industrial machines consume significant amounts of packaging materials that may not be recoverable.

Lack of flexibility: Switching between different drug shapes or packaging materials (e.g., from alu-plastic to alu-alu) can be time-consuming and labor-intensive.

Space constraints: R&D labs often have limited floor space, making large equipment impractical.

For these reasons, a dedicated blister-R&D machine isn’t a luxury—it’s a core piece of equipment for any serious drug-development facility. It must be compact, easy to operate, and capable of producing high-quality, stable packaging in small batches.

The Solution: The Grand Laboratory Blister Machine

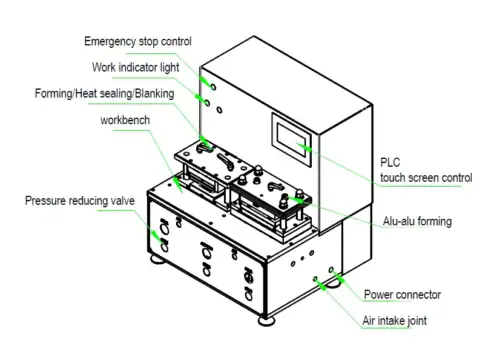

The Grand Laboratory blister machine is a smart, compact and high-capability solution, designed specifically for laboratories and small-batch production. Built by Guangzhou Grand Machinery, a technology-focused enterprise, this machine integrates blister forming, heat-sealing and cutting into a single stable, user-friendly unit.

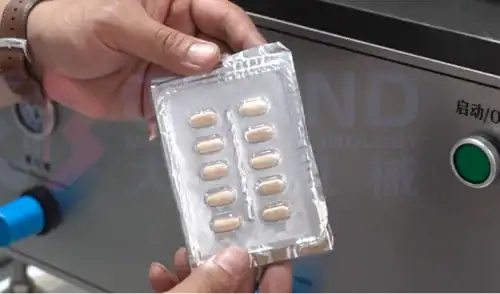

It supports both aluminum‐plastic (alu-plastic) and aluminum-aluminum (alu-alu) packaging—making it genuinely versatile for lab use.

Unmatched Versatility for Diverse R&D Needs

The primary strength of the Grand machine lies in its flexibility. It is not constrained to a single product type or packaging format.

Material compatibility: It handles thermoformable plastics (such as PVC or PVDC) for alu-plastic blisters, and cold-form aluminum foils for alu-alu packaging. This matters because different drugs demand different protection levels.

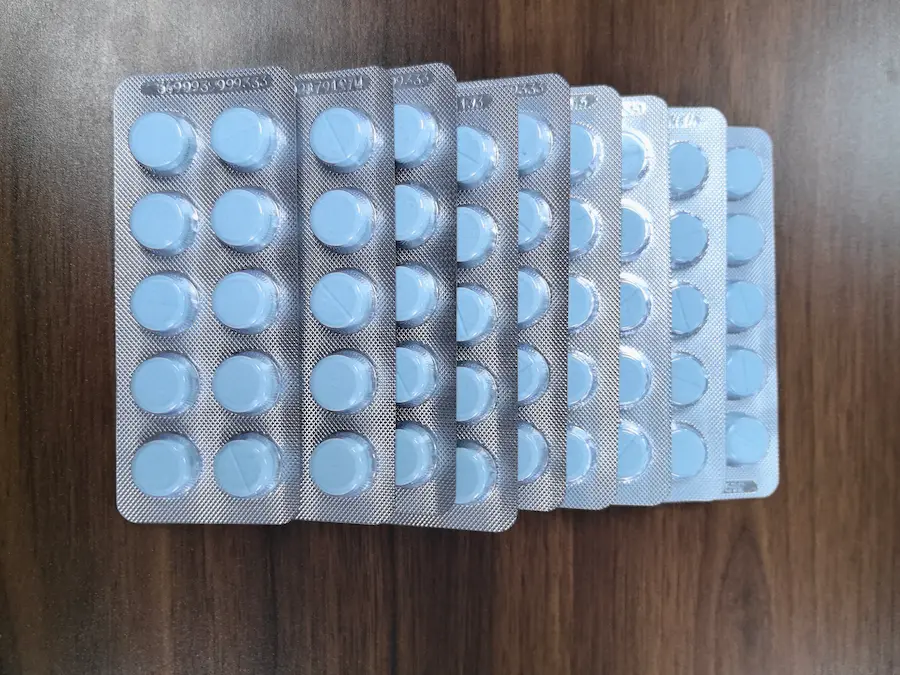

Product flexibility: With custom molds it can package a wide range of products—00 #, 0 #, 1 #, 2 # and 3 # capsules, round tablets, oblong tablets and other bespoke shapes.

High forming capability: It offers a maximum forming area of 110 mm × 120 mm, with a deep forming depth of up to 14 mm for alu-plastic and up to 10 mm for alu-alu cold-form. These figures enable packaging of larger tablets or higher-volume capsules.

Precision Engineering for GMP-Compliant Results

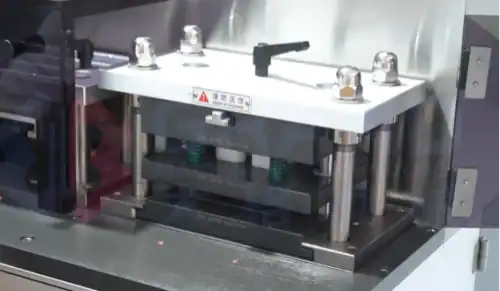

In pharmaceutical packaging, consistency is critical to ensure product stability. The Grand machine is built to deliver that level of precision.

Smart control interface: A Siemens SMART LINE touchscreen allows the operator to set and monitor all key parameters (upper and lower forming plate temperatures, heat-sealing station temperature) in an intuitive display.

Exceptional sealing integrity: The machine achieves heat-sealing accuracy of 99.9%. A near-perfect seal is vital for protecting the drug from moisture, oxygen and other environmental contaminants.

Positive-pressure forming: Instead of relying solely on vacuum forming, this machine uses positive air-pressure forming, which ensures the blister cavities have uniform wall thickness and deep, well-defined pockets—a major advantage when dealing with larger tablets or capsules.

The Science of Blister-Packaging Stability

The reliability of any laboratory-scale blister machine hinges on its ability to create a stable micro-environment for the drug. Both the choice of packaging material and the quality of the seal are among the most important factors in preventing drug degradation.

For example, studies on drug–excipient compatibility emphasise that interactions between the active pharmaceutical ingredient (API) and the excipients (and by extension the packaging environment) can significantly affect the stability of the final product.

In addition, packaging-seal integrity is recognised as vital: leaks or micro-channels—even those invisible to the naked eye—can allow ingress of moisture or oxygen, compromising sterility and stability.

Therefore, a machine like the Grand which can handle high-barrier materials (such as cold-form aluminum) and deliver very high sealing accuracy gives researchers the tools they need to perform robust stability studies.

Grand Laboratory Blister Machine: The Process in Detail

This semi-automatic blister machine simplifies the packaging process into a smooth, manually-controlled workflow, giving the operator full control at every step.

Blister forming

The operator places the forming film (e.g., PVC or cold-form aluminum foil) over the custom mould. Using the touchscreen interface, they start the forming heaters. A combination of heat and positive air pressure (0.4-0.6 MPa) pushes the film into the cavities, producing perfectly shaped blisters. The process is reliable and provides immediate visual feedback.Product filling and heat-sealing

After forming, the blister sheet is moved to the filling station where the operator manually places tablets or capsules into each cavity. A lidding foil (aluminum foil or other lidding material) is placed on top, and the sheet moves to the sealing station. With a single action, the machine applies precise heat and pressure, bonding the top film to the lidding foil with ~99.9% accuracy.If required, batch codes or expiry dates can be embossed during the sealing process.

Cutting

Finally, the sealed blister sheet moves to the cutting station. A precision die cuts out the final blister packs from the sheet, giving a clean, professional finish—ready for sample distribution, stability trials or small-scale release.

The entire workflow is intuitive and efficient. Depending on the operator, throughput is typically in the range of 200-700 units per hour—ideal for an R&D environment.

Compact Design, Powerful Performance

The Grand Blister R&D machine is engineered to deliver industrial-grade results in a lab-friendly footprint.

Dimensions: 635 mm × 575 mm × 710 mm—compact enough to sit on a standard lab bench or inside a small production room.

Power: Runs on standard 220 V supply and consumes only 2.6 kW—no special electrical infrastructure required.

Weight: Net 115 kg—a solid, stable machine that operates with low noise so it won’t disrupt the laboratory environment.

Why Choose Guangzhou Grand Machinery?

Guangzhou Grand Machinery isn’t just an equipment vendor—they position themselves as a technological partner. They combine R&D, manufacturing, marketing and after-sales service under a single roof, operating under core values such as “Quality First”, “Exquisite Manufacturing”, “Integrity-Based” and “Customer First.”

This philosophy is reflected in the build quality and reliable performance of the Laboratory Blister Machine, which has gained the trust of pharmaceutical companies, health-product manufacturers and hospital labs both in China and overseas.

If your organisation is serious about pharmaceutical development, the Grand Laboratory Blister Machine is the most reliable choice. It provides:

the flexibility to test different packaging formats;

the precision to produce GMP-compliant samples;

the efficiency to accelerate your R&D timeline.

Its ability to handle both alu-plastic and alu-alu formats, the user-friendly smart interface and the exceptional sealing accuracy (≈99.9%) all combine to make it the superior blister-packing machine for a laboratory environment.