Liquid Capsule Filling Machine: Introduce,Working Steps,DIY and Application

Capsules vs Tablets: Which is Right for You?

Features and applications of liquid capsule and soft capsule filling machines

Liquid capsule filling machines come in various types, such as fully automatic and semi-automatic machines. They are designed to fill hard capsules with liquids, sealing them securely for safety and stability. These machines are essential for filling capsules with liquid medicines or supplements.

Hard Capsule Filling:

These machines can fill capsules with liquids like solutions or suspensions. They seal the capsules tightly, ensuring the liquid remains secure during packaging and use. This technology is beneficial for dosing certain drugs and enhances the filling and sealing processes for medicines and supplements.

Performance and Features

High-Precision Filling: The machines ensure precise filling of each capsule using advanced systems. The filling volume difference is kept to about ±2%, ensuring accurate dosing.

Capsule Loading System: A vacuum system is used to position and separate capsules, achieving a loading rate of over 99%. The machine can detect missing capsules to maintain efficiency.

Automation and Efficiency: The fully automated system features a user-friendly interface. It alerts operators for missing capsules or materials, making it easy to use and boosting production efficiency.

Sealing Mechanism: The sealing system employs a servo motor for precise control, ensuring a strong seal for the liquid inside the capsules.

Sealing Trough Design: The trough has a heating and insulation system to maintain the adhesive's viscosity, which extends its life.

Drying and Curing Molds: The molds have a hanging, rotating design, making assembly and cleaning easier.

Main Purpose and Applications

- Pharmaceutical Uses:Liquid capsules are excellent for oral medications, particularly for drugs that are difficult to produce in solid form. They can hold liquid medicines, suspensions, and oils.

- Nutritional Supplements:They are popular for supplements like fish oil, vitamin E, and Omega-3 fatty acids, making it easy for users to take essential nutrients.

- Cosmetics:In the cosmetics industry, liquid capsules are used for facial serums, skincare oils, and hair care treatments, allowing for even application.

- Food and Beverages:They help deliver precise amounts of food additives, oils, and flavorings while keeping products fresh.

Comprehensive Solutions

The fully automatic soft capsule production line offers high productivity and top-quality packaging for the pharmaceutical, supplement, and cosmetics industries. This equipment uses advanced technology and has received certifications to ensure high-quality production.

Performance and Features

High Production Capacity: This equipment can produce up to 370 million capsules per year, depending on the model and usage.

Accurate Dosing: The machine uses a precise system to ensure dosing accuracy within ±2%, with a sealing rate of 98% or higher.

Advanced Water Cooling: A modern cooling system prevents contamination during production.

Low Lubricant Use: The lubrication system minimizes lubricant usage, simplifying cleaning.

High-Quality Transport System: The system uses FDA-approved conveyor belts that are safe and easy to clean.

Durable Mold Design: The molds are made from strong materials, ensuring durability over time.

Advanced Assembly: This design ensures stable performance, consistent quality, and high production rates.

Automatic Glue and Material Supply: The machine automatically supplies glue and materials, reducing manual labor and improving efficiency.

Gelatin Level Control: The equipment maintains a constant liquid level for easy adjustments during operation.

Safe, Non-Toxic Materials: All parts that come into contact with medicines are made from safe materials, ensuring user safety and easy cleaning.

Softgel Capsule Applications

- Pharmaceuticals: Softgel capsules are used to package both prescription and over-the-counter medications, allowing for precise dosage control.

- Nutritional Supplements:They are a popular choice for vitamins and herbal extracts, making it easy for users to take essential nutrients.

- Health Products:Softgels can hold oils and other health products that support various health benefits.

- Medical Oils:They are ideal for delivering various medicinal oils in a safe and effective manner.

- Herbal Extracts:Some herbal extracts are packaged in softgels for traditional remedies, allowing for easy consumption.

Technical Advantages and After-Sales Support

Automation Control: Advanced automation increases efficiency and precision in the production process.

Highly Customizable: The equipment can be tailored to meet specific production needs, making it versatile for different products.

Quality Control: A strict quality control system is in place to ensure product consistency and reliability.

After-Sales Support: A dedicated team offers technical support and training for users.

Lifetime Service: Continuous support is available for the equipment, ensuring long-term reliability.

Frequently Asked Questions (FAQ)

What products can this equipment package?

Pharmaceuticals, nutritional supplements, herbal extracts, and skincare products.

How can the equipment be adjusted for different products?

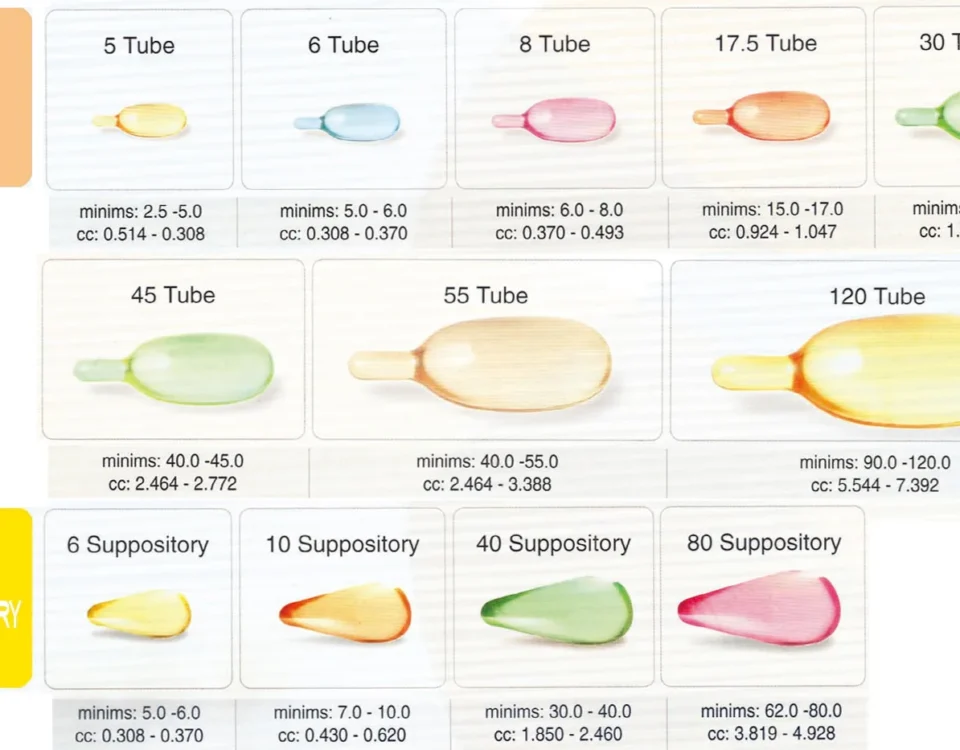

Simply replace the molds for different sizes and shapes.

How to clean and maintain the equipment?

Clean all surfaces after each batch, regularly inspect and lubricate drive components, and store the equipment in a dry area to avoid corrosion.

What is the production capacity?

The production capacity varies depending on the equipment; we can recommend the best option based on your needs.

Do you provide training and technical support?

Yes, our team offers comprehensive support, including installation and training for users.

Are there customization options?

Yes, we can customize the equipment to fit specific production needs.

What is the production process?

For hard capsules: feeding, separation, inspection, filling, locking, and sealing.

For soft capsules: ingredient preparation, gelatin preparation, compression, shaping, and drying.

What are the performance parameters?

Specific performance details are available based on your requirements.

Do the machines meet industry standards?

Yes, they comply with GMP standards and use high-quality materials for production.

What is the pricing structure?

We offer competitive prices as a direct manufacturer, providing great value for our equipment.

Are there upgrade options?

Yes, we can upgrade configurations based on your specific production needs.

What is the delivery and installation process?

We conduct a final inspection and provide ongoing support, including transportation and installation.

Do you have case studies or references?

Yes, we can provide detailed case studies upon request.

How can I get a quote?

Contact us via phone, email, or chat with your project details for a detailed quote tailored to your needs.