Why Metal Detection Machines Are Ideal for Pharmaceutical Packaging?

A Grandpack Counting Machine Begins Its Journey to Greece

Which Blister is Best for Medicine Packing?

Introduction

In the pharmaceutical industry, product safety is not just a goal. It is a requirement. Every tablet, capsule, and pill must reach the consumer in perfect condition. This is where medical blister packaging comes into play. It is the most common and effective way to protect medication. But with different materials and technologies available, manufacturers often ask: which blister is best?

This guide will explore the world of medical blister packs. We will look at materials, machinery, and the specific needs of different products. We will also discuss how advanced equipment, like the solutions from Grandpackmachine, can revolutionize your production line.

Understanding the Basics

First, we must understand what we are dealing with. What is a medical blister pack? Simply put, it is a unit-dose packaging format. It consists of a cavity or pocket made from a formable web. This usually contains the product. A lidding material then seals this pocket.

The primary goal is protection. The pack shields the drug from humidity, oxygen, and light. It also provides tamper evidence. If the seal is broken, the user knows. This level of security is vital for patient safety.

Expert Insight on Machinery

Choosing the right packaging is half the battle. Choosing the right machine is the other half. The efficiency of your production line depends on it.

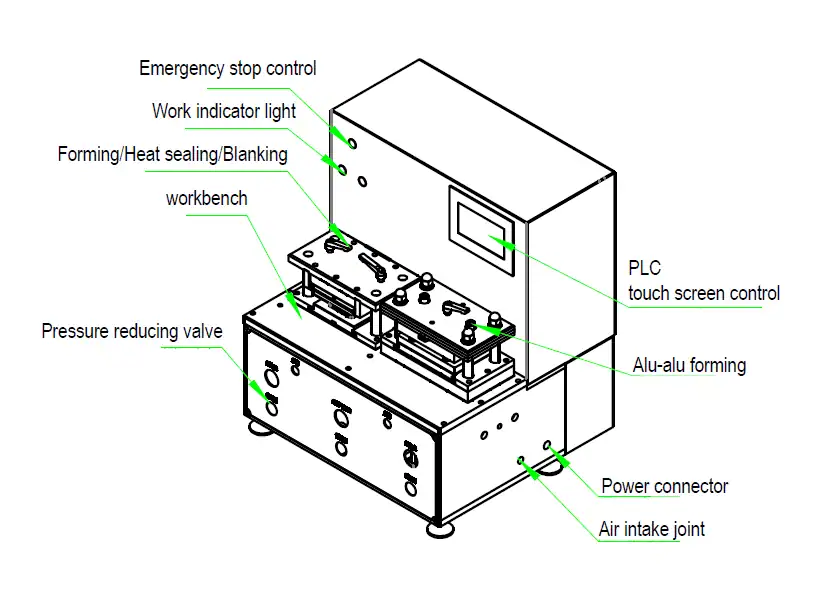

As our Sales Manager, Anna, explains: "The Grand Pharmaceutical Blister Machine-270 is designed for convenience with a logical layout. It integrates perfectly into production lines for mass packaging, making it the top choice for pharmaceutical and nutraceutical companies."

This design philosophy is crucial. A machine must be easy to clean and operate. It must fit seamlessly into a modern factory environment. The DPP-270 model exemplifies this with its balcony-style working platform. This design ensures there are no dead corners. Cleaning is fast. Maintenance is simple.

The Two Main Contenders: Alu/PVC vs. Alu/Alu

When asking "which blister is best," you usually choose between two types. These are Thermoforming (Alu/PVC) and Cold Forming (Alu/Alu).

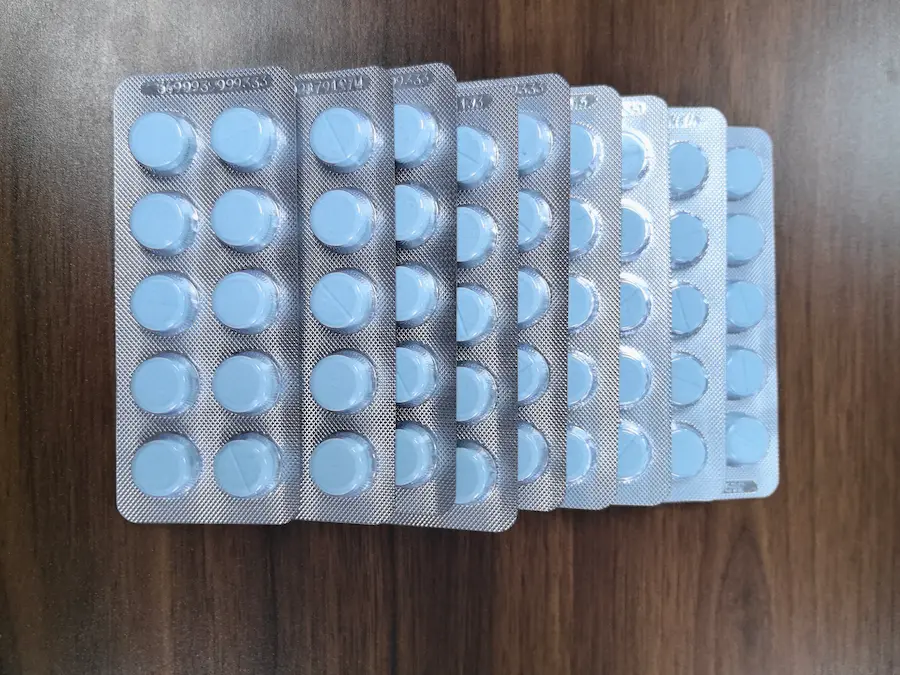

1. Thermoforming (Alu/PVC)

This is the most common type. The forming film is usually PVC. It is heated and then molded into a shape.

Pros: It is cost-effective. The plastic is transparent. Patients can see the product.

Cons: It offers moderate protection against moisture and oxygen.

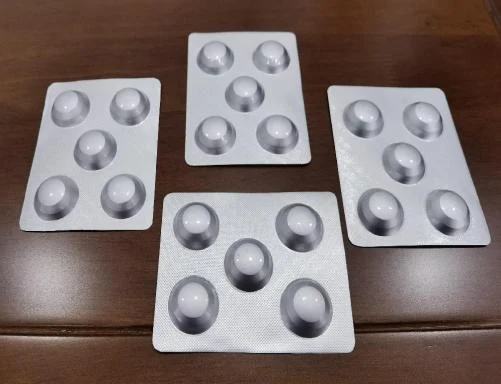

2. Alu Alu Blister Packaging (Cold Forming)

Alu alu blister packaging uses aluminum for both the base and the lid. No heat is used to form the cavity. The aluminum is stamped into shape.

Pros: It offers the highest possible protection. It creates a near-perfect barrier against moisture, light, and oxygen.

Cons: It is opaque. The product is not visible. It is generally more expensive than PVC.

What Material is Used for Blister Packaging?

The question of What material is used for blister packaging? has several answers. It depends on the barrier requirements.

PVC (Polyvinyl Chloride): The standard forming film. It is cheap and easy to thermoform.

PVDC (Polyvinylidene Chloride): often coated onto PVC. It improves the moisture barrier.

Alu (Aluminum): Used for the lidding foil. It is hard or soft tempered. In alu alu blister packaging, it is also the forming material.

Aclar: A polychlorotrifluoroethylene (PCTFE) film. It is transparent like PVC but offers a barrier similar to aluminum.

The Role of the Blister Packaging Machine

You cannot have a high-quality pack without a high-quality blister packaging machine. The machine determines the seal integrity. It determines the speed of production.

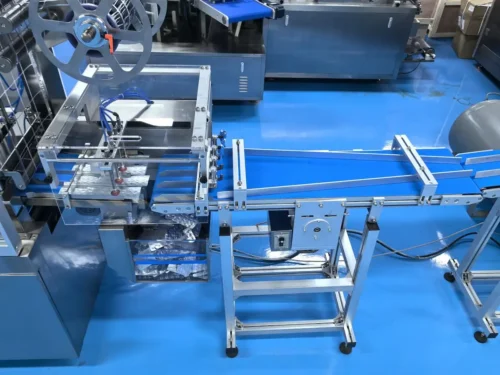

Servo traction station

At Grandpackmachine, our DPP-270 medical blister packaging machine is a versatile powerhouse. It is a "dual-purpose" machine. It can handle both Aluminum-Plastic (Thermoforming) and Aluminum-Aluminum (Cold Forming) packaging. This flexibility is vital for contract manufacturers. You do not need two separate machines.

Key Features of a Superior Machine:

- Servo Traction: The DPP-270 is equipped with servo traction. This ensures precise movement of the packaging material. The synchronization is perfect. This reduces waste and ensures the blister pockets are perfectly aligned.

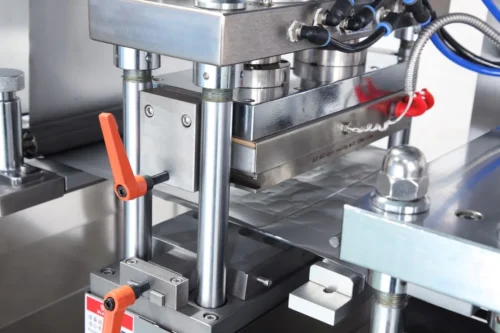

- Modular Design: Time is money. The DPP-270 features quick-connect molds. A single operator can change the molds in a short time. The forming, heat sealing, and punching mechanisms share a common positioning reference.

- GMP Compliance: In the medical field, hygiene is non-negotiable. Our machine uses high-quality 316 stainless steel for all parts contacting the drug. The frame is fully enclosed and easy to clean.

- Intelligent Control: The machine uses a Siemens PLC and touch screen. This allows for digital adjustment of the four working stations: forming, heat sealing, indentation, and punching.

Robotic arm removes slab conveyor belt

Which Blister is Best for Your Medicine?

So, which is best? The answer depends on your specific medication.

Choose Alu/PVC (Thermoforming) if:

Your drug is stable at room temperature.

Your drug is not highly sensitive to moisture.

Marketing requires the product to be visible.

Cost reduction is a primary goal.

Choose Alu/Alu (Cold Forming) if:

Your medication is highly hygroscopic (absorbs moisture).

Your medication is light-sensitive.

You need a longer shelf life in humid climates.

The product is high-value and needs premium protection.

The Grand DPP-270 supports both. You can switch production based on the order. It has a production capacity of up to 180 boards per minute for Alu/Plastic and 120 boards per minute for Alu/Alu.

Versatility: Beyond Just Pills

While we focus on medical blister packs, the technology is adaptable. A blister packing machine is not limited to tablets.

The DPP-270 has a large cam design. This allows for a maximum blister depth of 16mm. With customization, it can even reach 26mm. This makes it suitable for a wide range of industries:

Food Industry: Perfect for single-serve portions. Think of cheese, jam, butter, or ketchup. The hygiene standards of a pharma machine make it excellent for food.

Cosmetics: Blister packs are great for sample ampoules, creams, or lipstick refills.

Hardware & Electronics: Small screws, batteries, or vape cartridges fit perfectly.

Medical Devices: Syringes and needles need sterile barriers. The blister machine packing process ensures this sterility.

Addressing Common Consumer Questions

As a manufacturer, you must also understand your end-user. Here are common questions consumers ask about this packaging.

Do pharmacies still do blister packs?

Yes, absolutely. Do pharmacies still do blister packs? is a common query. In many regions, they are the standard. They are preferred for "compliance packaging." This helps elderly patients remember to take their daily dose. Hospitals use them extensively for unit-dose dispensing.

What medication cannot go in a blister pack?

What medication cannot go in a blister pack? Generally, almost any solid oral dose can be blister packed. However, there are exceptions.

Volatile medications: Drugs that might evaporate or degrade plastic need alu alu blister packaging.

Extremely fragile tablets: Some quick-dissolve tablets might break during the push-through process. These require "peel-off" backing instead of "push-through" foil.

Large Liquids: While small ampoules work, large liquid volumes are usually better suited for bottles.

The Importance of Detection and Safety

A blister packaging machine must do more than just seal. It must ensure quality. The DPP-270 offers optional detection systems.

- Vision Inspection: You can equip the machine with a camera detection system. This checks for missing tablets or broken pills before sealing.

- Automatic Rejection: If a pack is empty or faulty, the machine rejects it automatically. It uses a waste rejection mechanism.

- Safety Covers: The machine comes standard with safety covers for heat sealing and punching stations. If the cover is opened, the machine alarms. This protects your operators.

Technical Superiority of the Grand DPP-270

Let’s look deeper into why the DPP-270 is a market leader for medical blister packaging.

1. Precision Heating and Forming The forming station uses dedicated heating plates. The temperature is controlled by precise modules. This ensures the PVC or Alu film is soft enough to form but not melted.

Quick-connect molds for blister packaging machines

2. Robust Construction The main casting body is made of cast steel formed in one piece. It never deforms. This provides a stable base for high-speed operation. The center of gravity is stable, making the machine durable.

3. Separation of Drive and Operation The mechanical transmission is separated from the electrical zones. The electrical box is located at the back. This prevents heat from the motors affecting the sensitive films. It also makes maintenance safer.

4. Advanced Feeding The machine supports dedicated feeders. Whether you are packing capsules, flat tablets, or odd-shaped candies, the feeding station can be adapted. This ensures a high filling rate.

Choosing the Right Partner

Investing in medical blister packs technology is a big decision. You need a partner who understands the process.

Grandpackmachine offers more than just hardware. We offer expertise. We provide:

Full Validation: We help with GMP documentation.

Customization: We can adjust the machine height, mold size, and feeding system.

Support: We use top-tier components from Siemens, Schneider, and Omron. This ensures spare parts are available worldwide.

Conclusion

So, which blister is best for medicine packing? The answer lies in the balance between protection, cost, and patient convenience. For maximum protection, alu alu blister packaging is the king. For visibility and cost, PVC/Alu reigns supreme.

Regardless of your choice, the quality of the pack depends on the blister packaging machine. The Grand DPP-270 offers the versatility to run both materials. It gives you the freedom to adapt to market trends. It handles medicine, food, and cosmetics with equal ease.

Are you ready to upgrade your packaging line? Do you need a machine that offers the "design convenience" our manager Anna speaks of?

Contact Grandpackmachine today. Let us help you find the perfect medical blister packaging solution for your business. Ensure your product is safe, secure, and ready for the market.