Pharmaceutical Tablet Coating Machine

The GRAND-B-80E and 150E coating machines are efficient, compact systems for pharmaceutical and food product coatings.

Pharmaceutical Tablet Coating Machine

This Pharmaceutical Tablet Coating Machine Combination is mainly used for applying various protective and functional coatings to tablets, pills, and candies across pharmaceutical, food, and biotech industries.

Pharmaceutical Tablet Coating Machine Features:

High Efficiency and Quality:

The Grand-B film coating machine is designed to optimize efficiency. It shortens coating times, which increases productivity and improves quality.

Advanced Control System:

With its PLC control and easy-to-use touchscreen, the Grand-B automates key settings like air pressure, temperature, and drum speed.

Versatile Coating Options:

The machine can apply organic, aqueous, or sugar coatings, making it versatile. It’s suitable for coating tablets, pills, and candies, useful in pharmaceuticals, food, and biotech.

Compact and Compliant Design:

The Grand-B features a compact, space-saving design that meets CE and GMP standards.

Specifications

| Item | GRAND-B-80E | GRAND-B-150E |

|---|---|---|

| Max. Capacity | 80L / time | 150L / time |

| Coating Pan Diameter | φ930mm | Φ1200mm |

| Charging Mouth Diameter | φ380mm | Φ475mm |

| Coating Pan Speed | 1-19 r.p.m | 0-16 r.p.m |

| Main Machine Power | 1.5 kW | 2.2 kW |

| Exhaust Cabinet Power | 2.2 kW | 5.5 kW |

| Exhaust Cabinet Air Flow | 5268 m³/h | 7419 m³/h |

| Hot Air Motor Power | 0.75 kW | 1.5 kW |

| Air Inlet Cabinet Air Flow | 2356 m³/h | 2356 m³/h |

| Hot Air Temperature Range | ~80℃ | ~80℃ |

| Hot Air Purification Efficiency | 100,000 levels | 100,000 level |

| Peristaltic Pump Power | 0.37 kW | 0.37 kW (0.55 kW) |

| Silicone Pipe Wall Thickness | 1.6-2.2 mm | φ9×3.5 |

| Main Machine Dimensions (L×W×H) | 1370×1030×1950 mm | 1730×1320×2030 mm |

| Main Machine Weight | 600 kg | 850 kg |

| Air Inlet Cabinet Dimensions (L×W×H) | 1000×900×2170 mm | 900×800×2030 mm |

| Air Inlet Cabinet Weight | 450 kg | 480 kg |

| Exhaust Cabinet Dimensions (L×W×H) | 900×820×2000 mm | 950×950×1950 mm |

| Exhaust Cabinet Weight | 500 kg | 550 kg |

| Purified Air Pressure | ≥0.4 MPa | 0.4 MPa |

| Air Consumption | 0.4 m³/min | 1 m³/min |

| Water Pressure | ≥0.15 MPa | 0.15 MPa |

| Water Pipe Diameter | 1″ | 1 1/2″ |

| Steam Heating Pressure | ≥0.4 MPa | 0.4 MPa |

| Steam Consumption | 80 kg/h | 80 kg/h |

| Steam Heating Power | Three-phase, five-wire, 6 kW | Three-phase, five-line 10 kW |

| Electric Heating Power | Three-phase, five-wire, 32 kW | Three-phase, five-line 38 kW |

Why Choose Us

Innovative Customization

We tailor our coating machines to meet specific industry needs, from pharmaceutical controlled-release applications to versatile coatings for food and biotech.

Trusted Quality and Certifications

Recognized as a Zhejiang Province Key Technology product, our machines have passed rigorous evaluations and approved international CE and GMP standards.

Comprehensive After-Sales Support

We offer full support, from installation to training, ensuring seamless integration and optimal performance for every customer.

Commitment to Sustainable Solutions

Our efficient design minimizes energy consumption and environmental impact, helping customers achieve production goals sustainably.

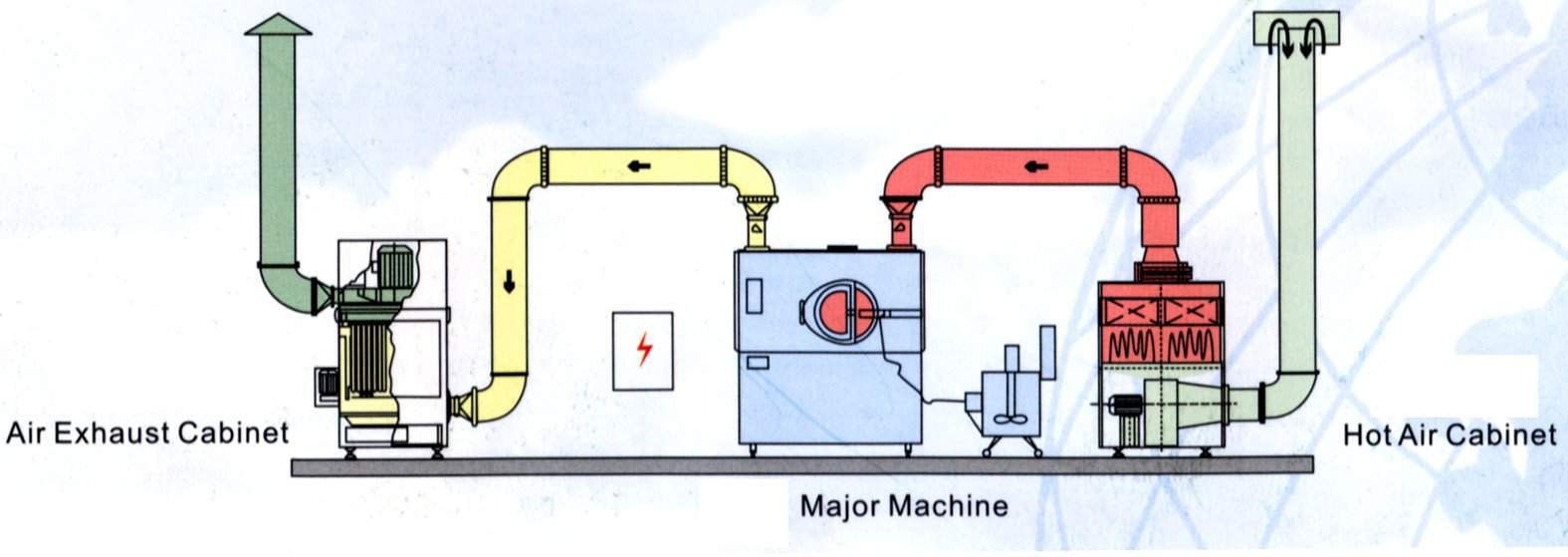

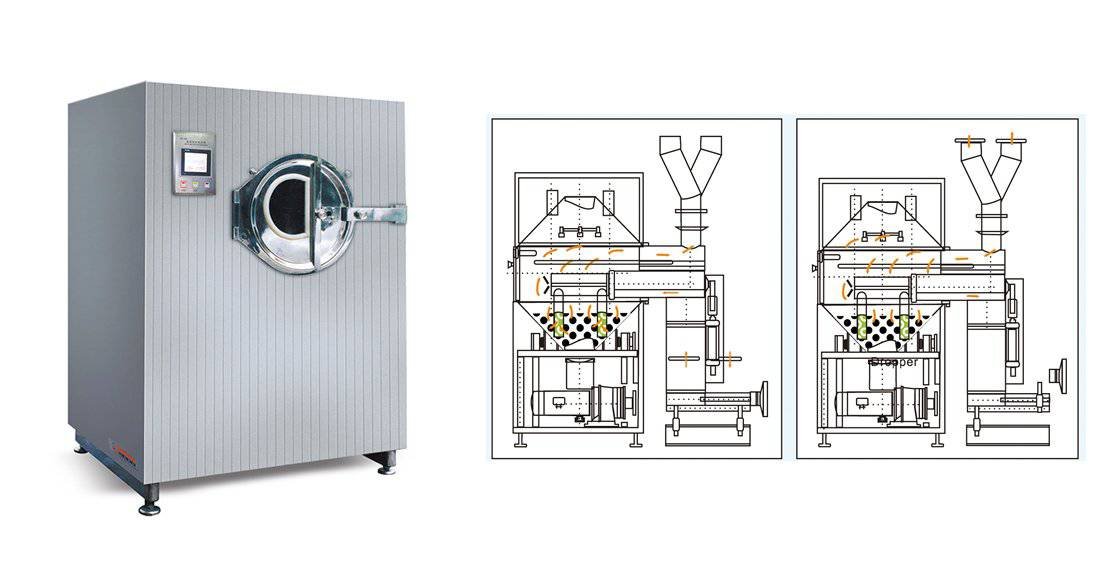

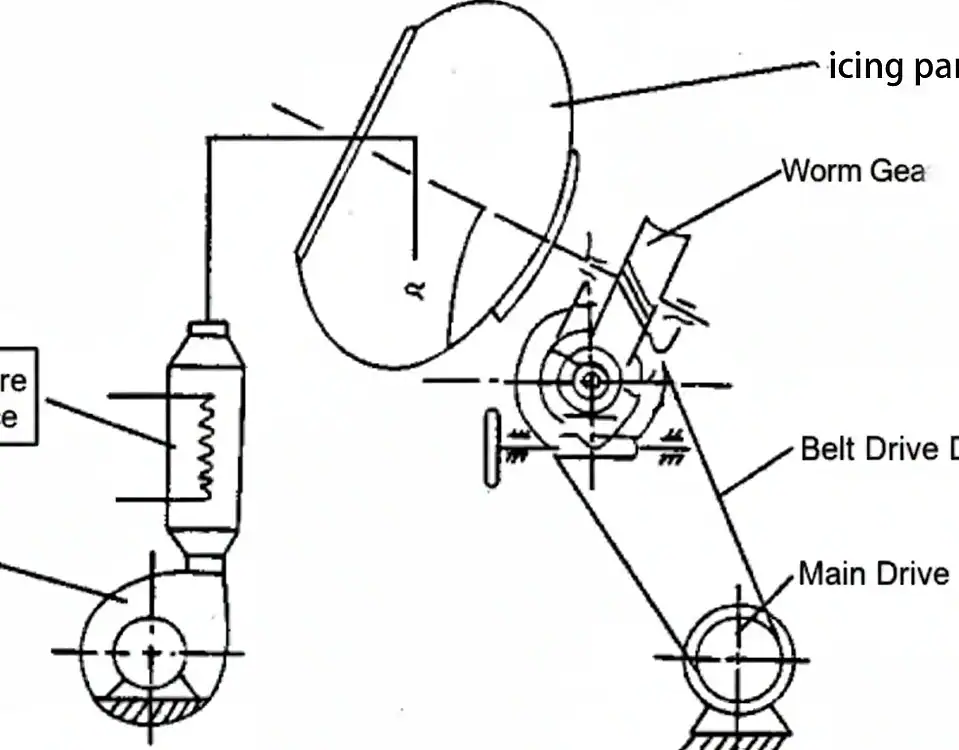

Main components

Major Machine

Hot Air Cabinet

Air Exhaust Cabinet

Mixing drum