Size Reduction Equipment by Grand Intelligent

Grand’s premium size reduction equipment. Explore Universal Pulverizers, Dust-Controlled Mills, Cryogenic Milling Systems, and more.

Product Overview

Microdizer-Pharmaceutical micro-pulverizer

Pulse dust removal crushing unit

Introduction

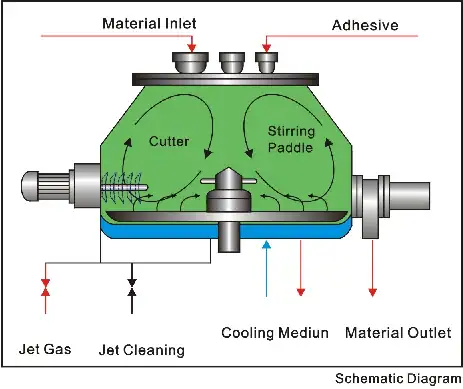

Dust-Controlled Mills

Grand’s size reduction equipment brings industry-leading performance to your production line.

From Pharmaceutical Size Reduction Equipment to heavy-duty grinders, our systems deliver uniform particle size, minimal heat buildup, and turnkey dust control. Simple setup. Precise results. Proven reliability.

Grand Pulverizer Categories

- Microdizer Systems

Ultra-fine milling down to 5 μm. Optimal for heat-sensitive APIs, pigments, and specialty chemicals. Universal Pulverizers / Grinders

Flexible mills that handle powders, granules, and fibers. Ideal for food spices, root vegetables, rubber, and more.Dust-Controlled Mills / Grinders

Integrated pulse-jet filtration captures 99.9% of airborne particles. Keeps your environment clean and compliant.Cryogenic Milling Systems

Low-temperature crushing for temperature-sensitive or volatile compounds. Preserves product integrity.

Grand Quality Features

GMP-Grade Construction

All stainless-steel contact parts. Smooth surfaces for easy cleaning. Conforms to 21 CFR § 211 standards.Self-Cooling Design

Continuous operation without heat buildup. Perfect for heat-sensitive materials like spices and pharmaceuticals.Precision Engineering

Tight clearances and balanced rotors for uniform particle distribution from coarse to ultrafine.Robust Components

High-durability bearings and industrial-grade motors ensure long service life and minimal downtime.

Functional Highlights

On-the-Fly Adjustments

Change grind settings with digital controls—no shutdown required. Achieve exact granularity from 0.5 mm to 5 μm.Cool-Running Operation

Advanced airflow design keeps the chamber temperature low, protecting thermally sensitive compounds.Continuous Production Capability

24/7 operation with automatic feed and discharge. Maximize throughput and reduce labor costs.Versatile Material Handling

Process chemicals, pharmaceuticals, food products, polymers, and more—all with the same platform.

Why Choose Grand?

- Cutting-Edge Technology

Proprietary vertical-shaft micro-crushing and reflective impact mechanisms deliver unmatched consistency. - High Efficiency & Yield

Optimized rotor designs reduce energy consumption while boosting output rates. - Safety & Compliance

Emergency-stop buttons, secure access panels, and ATEX-rated options for hazardous zones. - Global Support Network

Service centers across North America, Europe, and Asia. Expert technicians ready to assist. - Customizable Solutions

From skid-mount packages to fully automated lines—tailor your system to your exact process needs.

Machine Details

Sealing machine conveyor belt

Electromagnetic induction working position

FAQs

1. What materials can Grand’s size reduction equipment handle?

Our systems process a wide range of materials—from Pharmaceutical Size Reduction Equipment for APIs to food ingredients (spices, grains) and tough chemicals. Heat-sensitive and abrasive materials alike.

2. How is dust managed during milling?

Our Dust-Controlled Mills / Grinders feature built-in pulse-jet filters and cyclone separation. They trap particles before they escape the chamber, ensuring a clean, safe workspace.Read more:What is a Micro Pulverizer Used For?

3. Can I adjust particle size without stopping production?

Yes. Digital control panels allow real-time granularity adjustments. Shift from coarse pulverizing to ultrafine milling on the same run—zero downtime.

4. What makes Microdizer systems unique?

Microdizers use high-speed rotors and reflective micro-impact technology to achieve uniform sub-5 μm powders. Ideal for advanced formulations and specialty chemicals.

5. Are there options for cryogenic milling?

Absolutely. Our Cryogenic Milling Systems use liquid nitrogen cooling to lock in low temperatures—perfect for heat-sensitive or volatile compounds.

6. How do I maintain my pulverizer for peak performance?

Routine maintenance every 500 operational hours includes cleaning the chamber, inspecting rotors and bearings, and checking the filtration system. Replacement parts kits and service agreements are available.

Contact Us