Efficient & Intelligent Blister Card Packaging Machine-Best Solution

Grand fully automatic turntable blister card packaging machine is specially designed for semi-closed "paper card + blister" blister packaging. It adopts PLC intelligent control, touch screen operation and photoelectric automatic detection. It is suitable for multiple industries such as medicine, cosmetics, daily necessities, etc., and perfectly realizes blister card packaging.

Product Overview

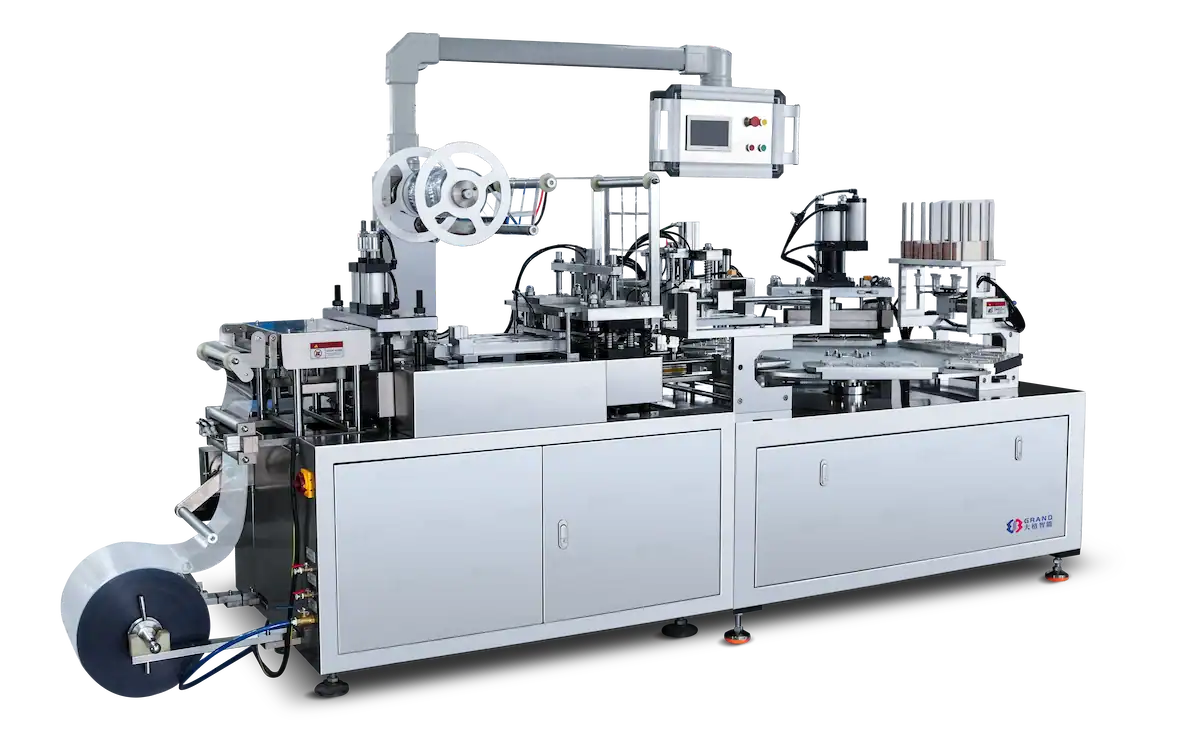

DGX-380 Blister Card Packaging Machine

DGX-380 fully automatic turntable blister card packaging machine is a new intelligent packaging equipment, dedicated to semi-enclosed "paper card + blister" blister packaging. The equipment uses advanced PLC control program, solid-state encoder and touch screen operation to achieve efficient, accurate and stable blister card packaging, which meets the packaging needs of various products.

Develop Your Business with Grand

Applications

Ideal for half-face blister packaging across various sectors including:

Pharmaceuticals: Medicines and health products

Cosmetics: Skincare and makeup products

Consumer Goods: Batteries, stationery, small hardware

Automotive: Automotive components

Food: Packaged snacks and other food items

Main Technical Specifications

| Technical Parameter | AC-400 | AC-380 |

|---|---|---|

| Packaging Materials | PVC/PET (0.18-0.5) × 400mm | PVC/PET (0.18-0.5) × 350mm |

| Compressed Air | Pressure 0.5-0.8 MPa, Air 40L/min | Pressure 0.5-0.8 MPa, Air 40L/min |

| Electricity Consumption | 380V 50Hz, 13kW | 380V 50Hz, 13kW |

| Mold Cooling Water | 50L/h | 50L/h |

| Machine Dimensions (L×W×H) | 4200 × 2500 × 1700 mm | 3700 × 2500 × 1700 mm |

| Weight | 2300 kg | 2000 kg |

| Production Capacity | 15-25 cycles/min | 15-25 cycles/min |

| Range of Travel | 50-220 mm | 50-160 mm |

| Maximum Cardboard Area | 420 × 220 mm | 400 × 200 mm |

| Maximum Molding Area & Depth | 380 × 220 × 40 mm | 350 × 160 × 40 mm |

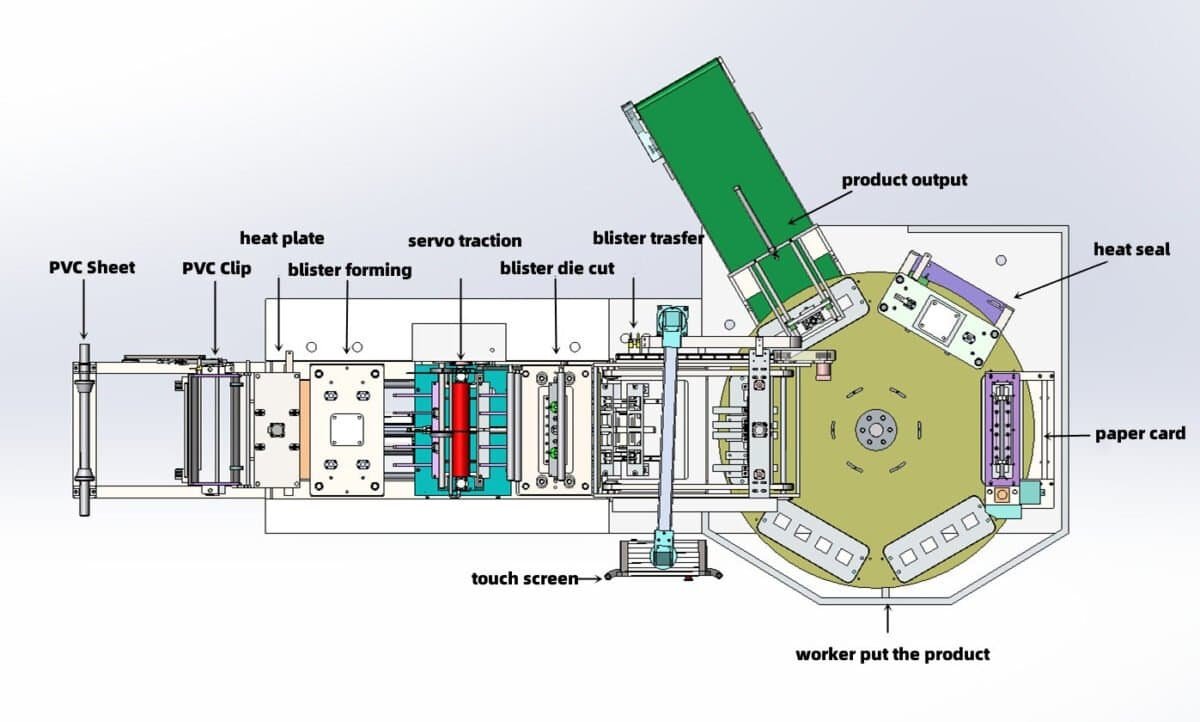

Mechanical composition

Technical Highlights

- Mechanical Drive: Servo motor traction with friction wheel reducer ensures smooth, stable performance.

- Automated Detection: Photoelectric sensors enable automatic detection, counting, and fault alerts, enhancing safety.

- Modular Mold Design: Easy to change molds quickly for different packaging requirements.

Cartoning machine details

High speed, high efficiency, high customization, all in Grand

Process

DGX-380-blister card packaging machine

PVC Unwinding

📜 Automatically unwind PVC material to prepare for blister formation.Blister Forming & Die Cutting

🔥 Efficient electric heating forms the blister, then precise die cutting shapes it perfectly.Scrap Recovery

♻️ Automatically recover excess material, ensuring an eco-friendly and efficient process.Product Placement & Paper Card Insertion

📦 Automatically place the product into the blister and insert the pre-folded paper card.Heat Sealing & Finished Product Output

🔒 Seal the packaging using heat sealing (with optional adhesive tape or hot melt glue) and automatically output the finished product.