Cartoner Machines – Efficient and Reliable Cartoning Solutions for Various Industries

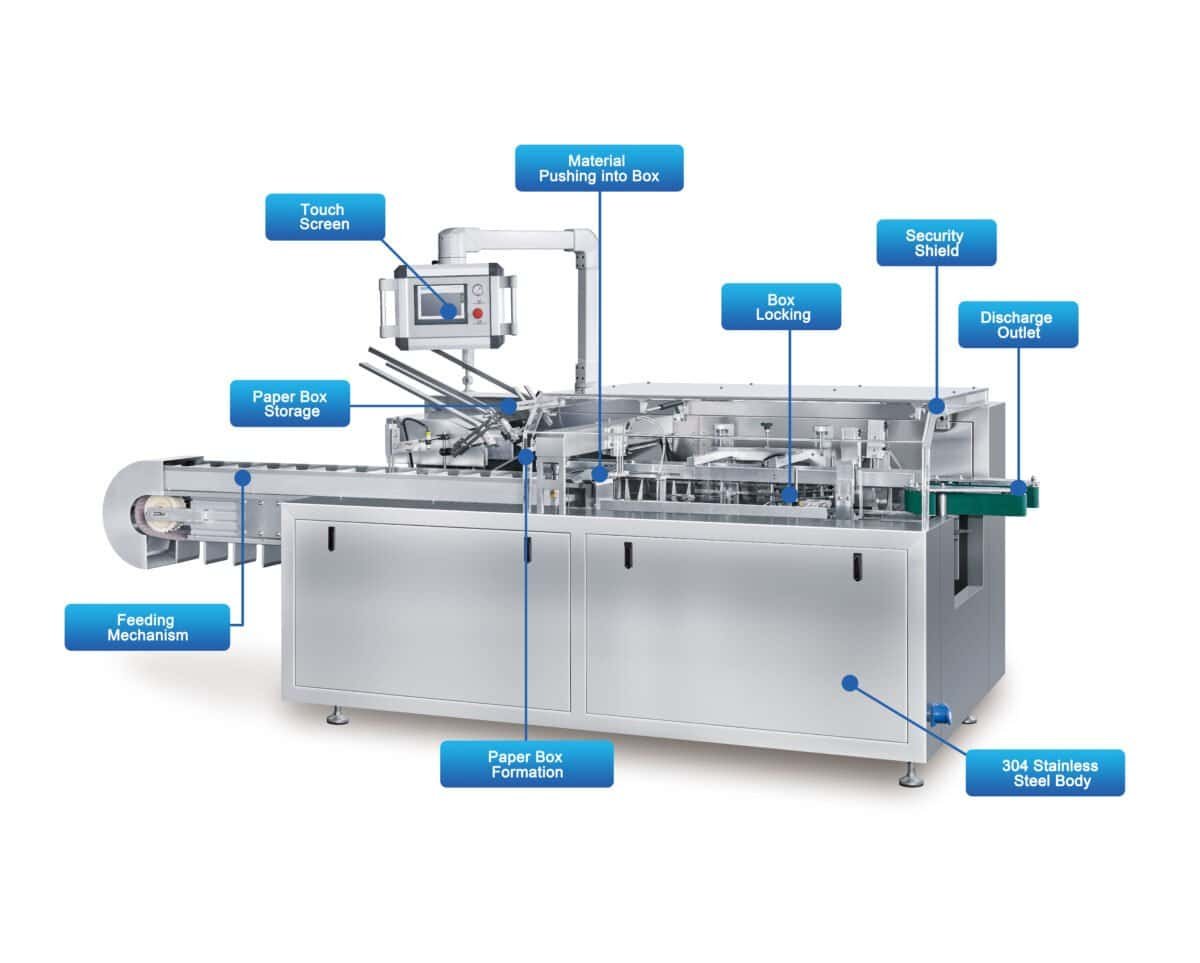

Grand cartoner machines are designed to automate the packaging process for a wide range of products across industries. Combining advanced technologies from both domestic and international sources, these machines deliver high-efficiency, compact designs, and flexible operations. With automatic feeding, box forming, leaflet folding (up to 4 folds), material insertion, batch number printing, and box sealing, our cartoners offer a full-scale solution to packaging needs.

Product Overview

The cartoner's design ensures easy adjustments through the control panel, enabling operators to set the number of boxes for each production batch. This versatile system supports a wide variety of packaging materials and product types, improving workflow and boosting overall production efficiency.

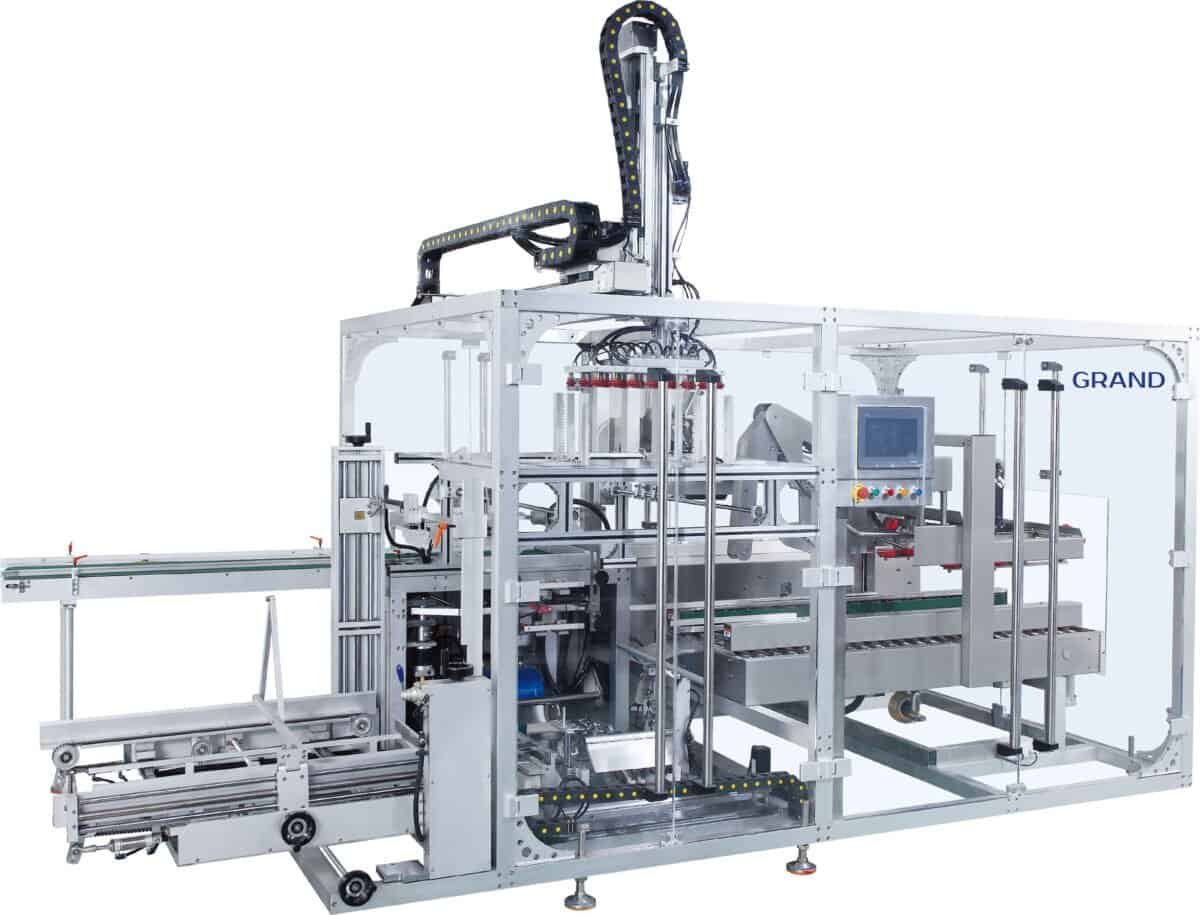

Check the Details:Vertical Cartoner Machine DGZ-120

Check the Details:DJ-50D Top-Opening Cartoning Machine

Check the Details:Case packing machine

Contact Us

Develop Your Business with Grand

DGZ-130 Cartoner – Our Top Recommended Model

The DGZ-130 Cartoner is our most recommended model for pharmaceutical and industrial packaging needs. With its robust design, customizable features, and high operational efficiency, it is the ideal choice for companies looking to streamline their packaging processes.

Our cartoners are perfect for the following industries:

Pharmaceuticals: Perfect for packaging tablets, capsules, and injectables.

Food & Beverages: Suitable for packaging chocolates, biscuits, liquids, sauces, and more.

Cosmetics: Ideal for personal care and cosmetic products.

Electronics: Packaging for devices, accessories, and components.

Industrial Products: Cartoning of industrial parts, automotive components, etc.

Medical Devices: For packaging medical tools and supplies.

Why Choose Our Cartoner Machine?

1. Flexible Application

Our cartoner is perfect for pharmaceuticals, food & beverages, cosmetics, medical devices, electronics, and more. It handles different product sizes, shapes, and materials like tablets, capsules, vials, and consumables.

2. Fully Automated Process

The machine automates the entire cartoning process—from material feeding and leaflet folding to carton sealing—reducing manual labor and ensuring accurate, high-quality packaging.

3. High Performance & Customization

With adjustable feeding mechanisms, our cartoner runs at speeds of 30 to 120 boxes per minute, easily adapting to different products and packaging needs.

4. Space-Saving & Cost-Effective

Its compact design saves space and is ideal for plants with limited floor area. The PLC control system ensures smooth performance and boosts production efficiency.

5. Easy Operation

Featuring a user-friendly interface, the machine offers automatic overload protection and self-diagnosis, providing real-time alerts for easy maintenance and minimizing downtime.

Main Technical Specifications

| Specification | Value |

|---|---|

| Cartoning Speed | 30-120 boxes/min |

| Box Material | 250-350g/㎡ (depending on box size) |

| Box Size | 70-200mm x 35-120mm x 14-70mm |

| Leaflet Folding | 1-4 folds (80-250mm x 90-170mm) |

| Power Supply | 380V, 50Hz |

| Air Pressure | ≥0.6MPa with a consumption of 120-160L/min |

Paper box type

No matter what material or shape of the paper box, you can design it for free and find the corresponding solution here

Advanced Automation – Automatic carton opening, product insertion, leaflet folding, batch printing, and sealing all take place in one continuous process.

Customizable for Different Products – Supports various materials like blister packaging, bottles, and vials, making it suitable for the pharmaceutical, food, cosmetics, and electronics industries.

GMP Compliance – The machine adheres to the high standards required for GMP (Good Manufacturing Practice), ensuring product safety and regulatory compliance.

Efficient Performance – High-speed operation of 30-120 boxes per minute, reducing overall packaging time and increasing throughput.

Precise and Accurate – Handles all types of packaging materials with precision, minimizing wastage and ensuring the correct number of products in each box.

Cartoning machine details

Grand cartoning machine is precise and efficient, and is the first choice for enterprises in cartoning

Pre Folding Carton Type

Pre Folding Carton Type Diagram

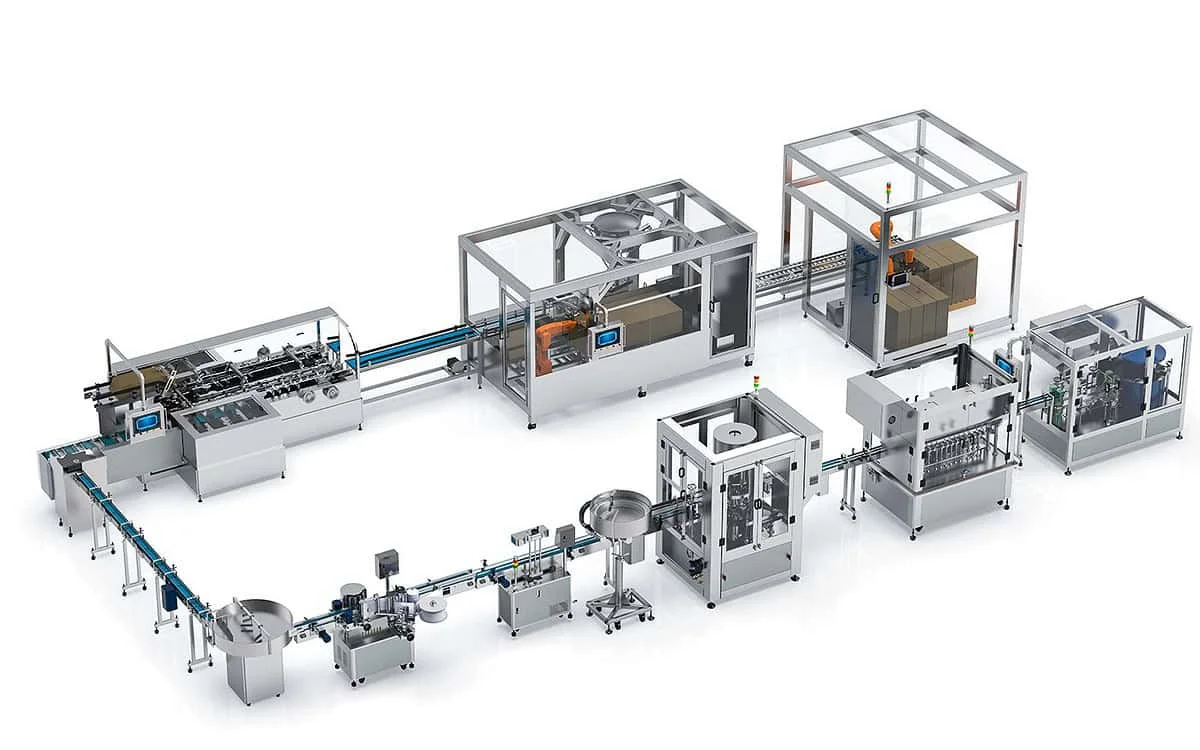

Highly efficient compatibility and customization

Free combination of grand packaging production lines, full line compatible, including blister packaging production line, solid dosage production line, soft candy production line, etc.

Cartoning production line