How high-speed tablet machine revolutionize production?

6 Maintenance Tips and Solutions for Three-Dimensional Dry Powder Mixers

3 Critical Roles of Pill Coating Machines in Medical Research

In today’s competitive pharmaceutical landscape, advanced pill coating machines have become indispensable. These devices not only ensure that tablets are aesthetically appealing but also play a crucial role in drug stability, targeted delivery, and quality control—three aspects essential for effective medical research and development.

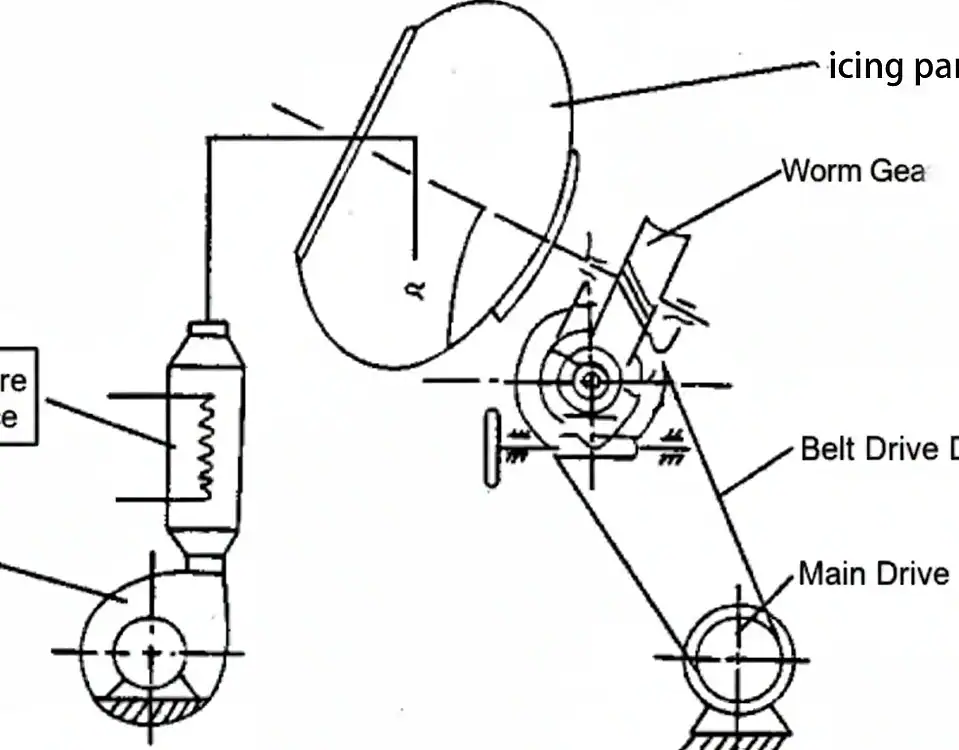

coating system

With emerging studies, such as the recent Nature publication on aspirin’s role in enhancing immune responses against cancer metastasis in mice, the significance of optimal drug formulation is clearer than ever. This blog delves into the 3 pivotal functions of pill coating machines and how they empower researchers and manufacturers worldwide.

1. Enhancing Drug Stability and Efficacy

One of the primary functions of a pill coating machine is to improve the stability and efficacy of drugs. The coating process acts as a protective barrier against environmental factors like moisture, oxygen, and light, which can degrade active pharmaceutical ingredients (APIs) over time.

A. Protecting Active Ingredients

The protective layer applied by a pill coating machine minimizes chemical interactions with the external environment. For instance, many drugs—aspirin included—are prone to hydrolysis or oxidation. A uniform coating prevents these degradation pathways, ensuring that the drug retains its intended therapeutic effect throughout its shelf life.

A mathematical representation of the coating’s protective efficacy can be modeled by the equation:

E = M / (ρ × A)

where:

- E represents the effective coating thickness,

- M is the mass of the applied coating material,

- ρ denotes the density of the coating, and

- A is the surface area of the tablet.

By maintaining an optimal value for E, manufacturers guarantee that the tablet’s active ingredient is sufficiently shielded.

ARHGEF1 can inhibit T cell immunity against cancer metastasis. Source: Yang, et al.

B. Controlled Release Profiles

Beyond protection, pill coating machines are designed to modulate the release of the API. By adjusting the coating formulation and thickness, researchers can control the drug’s dissolution rate. This controlled release is critical for drugs that require a steady therapeutic concentration over time.

For example, in the context of the aspirin study published in 《Nature》, achieving an optimal release profile might enhance the immune response against cancer metastasis. An appropriately coated tablet ensures that aspirin’s active ingredients are delivered at a rate that maximizes their biological impact without causing adverse side effects.

C. Advantages Over Uncoated Tablets

Uncoated tablets, while simpler to produce, often suffer from inconsistent bioavailability and stability. In contrast, tablets produced with advanced tablet coating equipment offer:

- Uniformity: Each tablet receives a consistent layer of coating, reducing variability in drug performance.

- Enhanced Shelf Life: The protective barrier prolongs the shelf life of sensitive medications.

- Improved Patient Compliance: Coated tablets are generally easier to swallow and have a more palatable taste.

These advantages make pill coating machines a vital asset for both research and commercial manufacturing.

2. Optimizing Bioavailability and Targeted Delivery

A well-designed pill coating machine not only protects and preserves the API but also optimizes its bioavailability and delivery to the target site. This function is particularly crucial in the development of novel therapies and combination treatments.

A. Improving Bioavailability

Bioavailability refers to the proportion of the drug that enters circulation and can have an active effect. The tablet coating process can be fine-tuned to control how quickly a tablet disintegrates, thereby enhancing the drug’s absorption in the gastrointestinal tract. For instance, enteric coatings prevent the tablet from dissolving in the stomach, ensuring that it releases its active ingredient only when it reaches the more neutral pH environment of the intestines.

Such precision is vital in maximizing the therapeutic impact of medications. Researchers often rely on advanced pill coating machines—or, more broadly, tablet coating equipment—to produce formulations with predictable and reproducible bioavailability profiles.

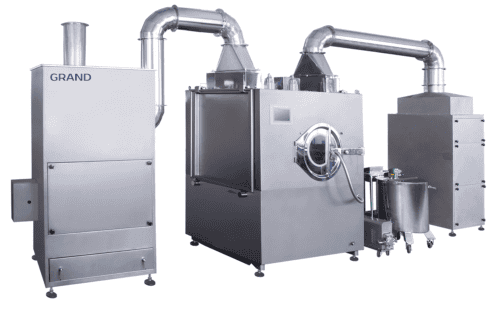

Pharmaceutical Tablet Coating Machine

B. Enabling Targeted Delivery

Targeted drug delivery is a growing focus in medical research. By incorporating specialized coatings, tablets can be engineered to release their payload at specific sites within the body. For example, a delayed-release formulation may be used to target the colon or other regions where the drug is most needed.

The principles underlying targeted delivery can be understood through the concept of time-release kinetics. Using first-order kinetics, the rate of drug release (dC/dt) can be modeled as:

dC/dt = -kC

where:

- C represents the concentration of the drug, and

- k is the rate constant specific to the coating properties.

By adjusting the value of k—which is directly influenced by the coating’s thickness and composition—manufacturers can design tablets that meet precise therapeutic needs.

C. Synergy with Immune-Modulating Therapies

Recent research, such as the aspirin study in Nature, suggests that optimizing drug release may have implications beyond basic treatment. Enhanced bioavailability can synergize with immune-modulating therapies to improve outcomes in diseases like cancer. This interconnection underscores the broader impact of high-quality pill coating machines in modern medical research.

3. Ensuring Manufacturing Consistency and Quality Control

Consistency is the cornerstone of pharmaceutical manufacturing, particularly when scaling up production for clinical trials or commercial distribution. Advanced tablet coating machine manufacturers have refined their equipment to deliver unparalleled uniformity and reproducibility in tablet production.

A. Automated Precision and Control

Modern grand tablet coaters incorporate cutting-edge automation and sensor technologies. These machines monitor critical parameters in real time—such as coating thickness, temperature, and humidity—to ensure that every tablet meets stringent quality standards. Automation minimizes human error and enhances the repeatability of the manufacturing process.

B. Quality Assurance Through Real-Time Monitoring

Real-time monitoring and control systems integrated into tablet coating machines enable continuous quality assurance. Data gathered during production can be analyzed using statistical process control (SPC) methods, which help identify deviations from the set parameters. An example of an SPC formula is:

σ = √(Σ(xᵢ - μ)² / N)

where:

- σ is the standard deviation,

- xᵢ represents individual measurements,

- μ is the mean, and

- N is the number of observations.

By keeping σ within an acceptable range, manufacturers can ensure that each tablet is coated uniformly—a critical factor in both drug efficacy and regulatory compliance.

C. Advantages of Consistency in Medical Research

Uniformity in tablet coating is not only a manufacturing goal but also a research imperative. Inconsistent formulations can lead to variable clinical outcomes, undermining the validity of experimental data. For medical researchers, reliable and reproducible tablet formulations—delivered by state-of-the-art pill coating machines—are essential for developing and validating new therapies.

Furthermore, high consistency facilitates easier regulatory approvals and bolsters confidence in the therapeutic claims of new drugs. This level of precision and reliability is a hallmark of the best tablet coating machine manufacturers and the advanced tablet coating equipment they produce.

Conclusion

The integration of advanced pill coating technology into pharmaceutical manufacturing has a profound impact on drug development. The three critical roles—enhancing drug stability and efficacy, optimizing bioavailability and targeted delivery, and ensuring manufacturing consistency—collectively contribute to the creation of superior tablet formulations.

By protecting active ingredients, controlling release profiles, and ensuring consistent quality, modern pill coating machines are indispensable tools in both research and commercial production. Their ability to fine-tune bioavailability and enable targeted delivery paves the way for innovative therapies, such as the potential immune-enhancing effects of aspirin observed in recent Nature research.

As the pharmaceutical industry continues to evolve, investing in high-quality pill coating machines—whether you refer to them as a pill presser, tablet coating equipment, or simply a grand tablet coater—will be crucial for advancing medical research and achieving breakthroughs in patient care.

References

- Nature. (2025). Aspirin Enhances Immune Response Against Cancer Metastasis in Mice. Retrieved from Nature.

- Additional reference details from internal research and technical documentation provided by leading tablet coating machine manufacturers.