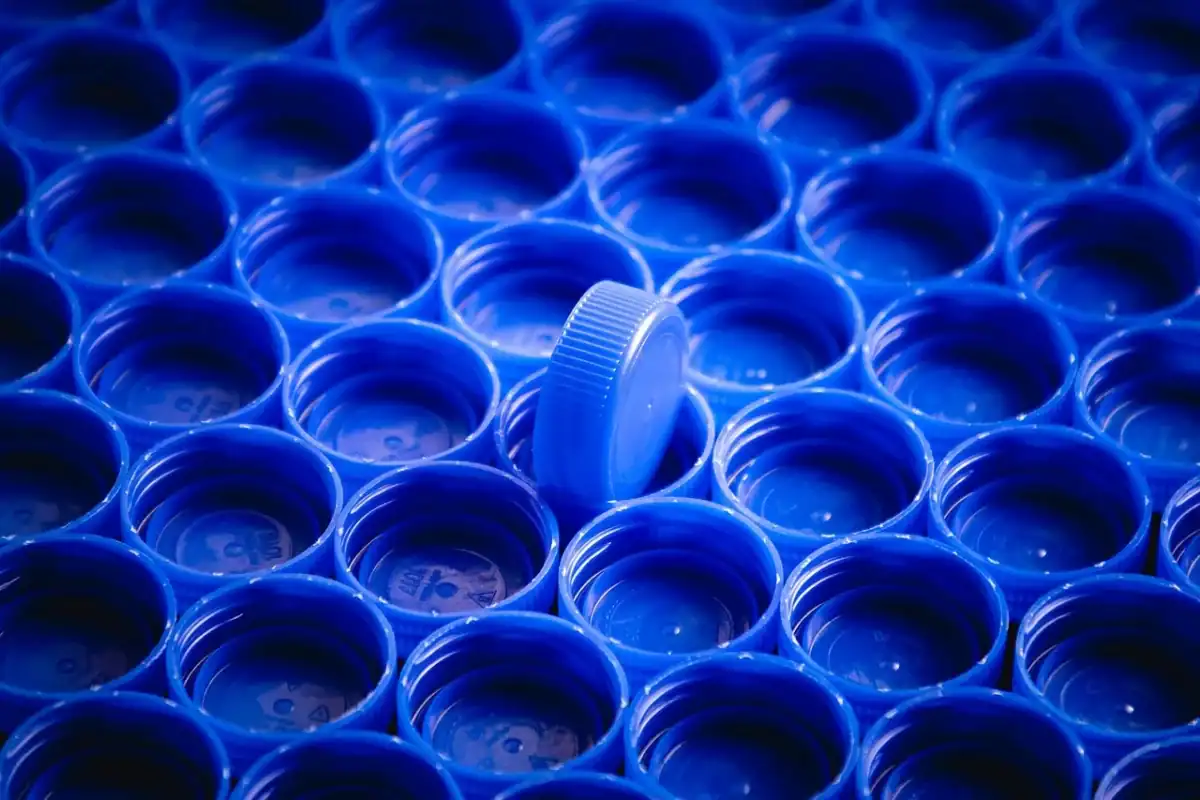

GV1300: The Ultimate AI-Powered Bottle Cap Auto Inspection Machine

In high-volume manufacturing, a single defective bottle cap can compromise an entire product line, leading to costly recalls, production downtime, and damage to your brand's reputation. Manual inspection is slow, inconsistent, and incapable of meeting the demands of modern production.

The Grand GV1300 Bottle Cap Packaging Inspection Machine is the definitive solution. As a state-of-the-art auto inspection machine, the GV1300 leverages the power of deep learning AI and advanced industrial vision systems to deliver flawless quality control. It automates the critical process of surface defect detection and compliance verification, empowering cosmetics, food & beverage, and pharmaceutical manufacturers to achieve 100% zero-defect delivery with unmatched speed and precision.

Develop Your Business with Grand

Unrivaled Features of the GV1300 Inspection Machine

1. Unmatched Defect Detection with AI & Multi-Spectral Imaging

Traditional machine vision systems often fail when inspecting reflective, transparent, or complex materials. The GV1300 overcomes this with a high-resolution 20MP multi-spectral camera. This technology, combined with our proprietary deep-learning AI, penetrates reflective surfaces and ignores visual noise.

2. Comprehensive 360° Quality Coverage

Why use multiple machines when one can do it all? The GV1300 integrates seven critical inspection tasks into a single, compact footprint. It meticulously examines every surface for:

Surface contamination (dirt, stains, black spots)

Physical damage (scratches, scuffs)

Molding flaws (material buildup, sink marks)

Deformation (ovalization, height variance)

Internal defects (excessive burrs, flashing)

Missing internal serial numbers or codes

Incomplete or damaged threading

3. High-Speed Precision for Maximum Throughput

The GV1300 is built for the pace of modern industry. With a standard inspection speed of 200-400 pieces per minute, it seamlessly integrates into your production line. Dynamic tracking technology ensures flawless performance with various feeding systems, including vibratory bowls and conveyor belts. For operations requiring even greater velocity, we offer customized solutions to boost speeds up to 600 pieces per minute. This inspection machine doesn't just find defects; it links directly to rejection mechanisms to instantly sort and remove faulty units in real-time.

4. Intuitive, Code-Free AI Model Training

Adapting to new products shouldn't require a team of engineers. Our self-developed AI training platform is designed for your factory floor technicians, not programmers. To configure the GV1300 for a new cap design, simply upload samples of defective products.

5. Intelligent Self-Diagnostics for Maximum Uptime

Unplanned downtime is a profit killer. The GV1300 features an intelligent self-diagnostic system that constantly monitors its own operational health.

Industry Comparison: The GV1300 vs. Traditional Methods

| Feature | GV1300 AI Inspection Machine | Traditional Machine Vision | Manual Inspection |

|---|---|---|---|

| Accuracy | Exceptional. Detects flaws ≥0.3mm² & dimensional tolerances of ±0.1mm. AI distinguishes true defects from visual noise. | Moderate. Struggles with reflective/transparent surfaces and complex backgrounds. High false positive rate. | Poor & Inconsistent. Subject to human error, fatigue, and subjective judgment. |

| Speed | Very High. 200-600 pieces/minute. Keeps pace with the fastest production lines. | High. Speed is often limited by processing power and algorithm complexity. | Very Slow. Typically 20-30 pieces/minute per person. |

| Consistency | Perfect. 100% repeatable inspection, 24/7. Every cap is judged by the same precise standard. | Good. Consistent but may require frequent recalibration for minor environmental changes. | Low. Performance varies significantly between inspectors and throughout a shift. |

| Defect Types | Comprehensive. Catches surface, dimensional, internal, and character-based defects in one pass. | Limited. Typically focused on 2D surface flaws. Requires multiple systems for different defect types. | Limited. Ineffective at seeing internal burrs or precise dimensional errors. |

| Adaptability | Excellent. New product models trained in 30 minutes via a code-free interface. | Poor. Requires expert programming and significant downtime to adapt to new products. | Good. Humans can adapt easily but require extensive training for each new product. |

Application Scope: Your Partner in Quality Across Industries

The GV1300 auto inspection machine is engineered for versatility, providing critical quality control at key production stages.

At the Point of Production: Install the GV1300 directly after your injection molding or stamping machines for 100% in-line inspection. Instantly identify and remove defective caps, preventing flawed inventory from accumulating and providing immediate feedback to optimize your molding process.

Final Pre-Packaging Quality Assurance: Position the GV1300 as the final gatekeeper before filling and sealing. It intercepts any caps that were contaminated or damaged during transit or storage, eliminating the risk of costly rework after the product is filled.

Versatile Material and Finish Adaptability: Our advanced industrial vision systems are not limited by material. The GV1300 expertly inspects plastic, metal, and glass caps, performing flawlessly on any finish, including transparent, matte, high-gloss, and coated or metallized surfaces.

Why Choose the GV1300?

Choosing the GV1300 is an investment in perfection, efficiency, and brand protection. As a premier auto inspection machine and precision measuring device, it delivers a powerful return on investment.

Guarantee Zero-Defect Delivery: Eliminate shipping defects, protect your customers, and build a reputation for uncompromising quality.

Dramatically Reduce Costs: Cut expenses related to manual labor, customer returns, product recalls, and wasted materials from post-fill rework.

Boost Operational Efficiency: Maximize your throughput with high-speed, automated inspection and reduce costly downtime with intelligent diagnostics.

Future-Proof Your Production: With its easy-to-train AI and adaptable hardware, the GV1300 is a long-term solution that grows with your business and product lines.

FAQs for Machine

1. Our bottle caps are highly reflective and transparent. Can the GV1300 reliably inspect them?

Absolutely. This is a core strength of the GV1300. Traditional machine vision systems are blinded by glare and reflections. Our system uses multi-spectral imaging and powerful AI algorithms that are specifically designed to penetrate transparent materials and normalize reflections, allowing it to see the actual surface and detect defects with incredible accuracy where other systems fail.

2. How difficult is it to set up the GV1300 for a new bottle cap design?

It's remarkably simple and fast. You do not need any programming skills. Using our intuitive AI training platform, you simply feed the machine a small batch of samples for the new cap, including samples with known defects. The system analyzes them and automatically builds a new inspection model. The entire process, from upload to a production-ready model, can be completed in under 30 minutes.

3. Can this inspection machine keep up with our existing high-speed production line?

Yes. The GV1300 is engineered for speed, with a standard throughput of 200-400 pieces per minute. Its dynamic tracking technology allows for seamless integration with high-speed conveyors and vibratory bowl feeders without sacrificing accuracy. If your line runs even faster, we can provide a customized solution to meet speeds of up to 600 pieces per minute.

4. What kind of ongoing maintenance or support is required?

The GV1300 is designed for robust, low-maintenance operation. The built-in self-diagnostic system actively monitors all components and will alert you before a problem occurs, scheduling maintenance at a convenient time to prevent unplanned downtime. Furthermore, our systems are supported by a global team of technical experts for remote and on-site assistance.

5. How does the GV1300 provide a return on investment (ROI)?

The ROI is multifaceted and rapid. Financially, you save immediately by reallocating or reducing manual labor costs. Operationally, you eliminate the massive expenses associated with customer returns, rework, and potential product recalls. Most importantly, by guaranteeing 100% quality, the GV1300 protects your most valuable asset: your brand's reputation for excellence, which drives customer loyalty and long-term growth.