Blister Packaging Production Line

At Grand, our state-of-the-art Blister Packaging Production Line is designed to meet the rigorous demands of the pharmaceutical industry. Whether you require semi-automatic or fully automatic solutions, our production lines boost speed, capacity, and overall performance. With millions invested annually in R&D, we ensure our technology remains at the forefront of industry innovations.

Contact Us

Develop Your Business with Grand

Key Features

Core Product Excellence:

Our blister machine line is our flagship offering—providing a professional blister pack solution tailored to your needs.

Significant Investment:

We invest heavily every year to enhance the quality, speed, and capacity of our blister machines, ensuring optimal operating performance.

Industry Presence:

Our innovations are showcased annually at leading Pharmaceutical Machinery Exhibitions, keeping us ahead of market trends.

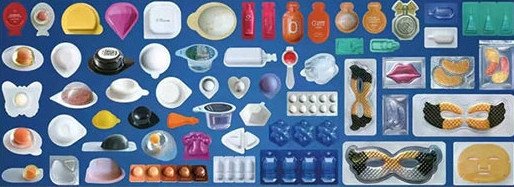

Versatile Packaging:

Our production lines accommodate a range of materials, including PVC, PP, and aluminum, catering to diverse product requirements.

Flexible Pricing:

We offer solutions from semi-automatic to fully automatic setups, customized to match your production capacity and budget.

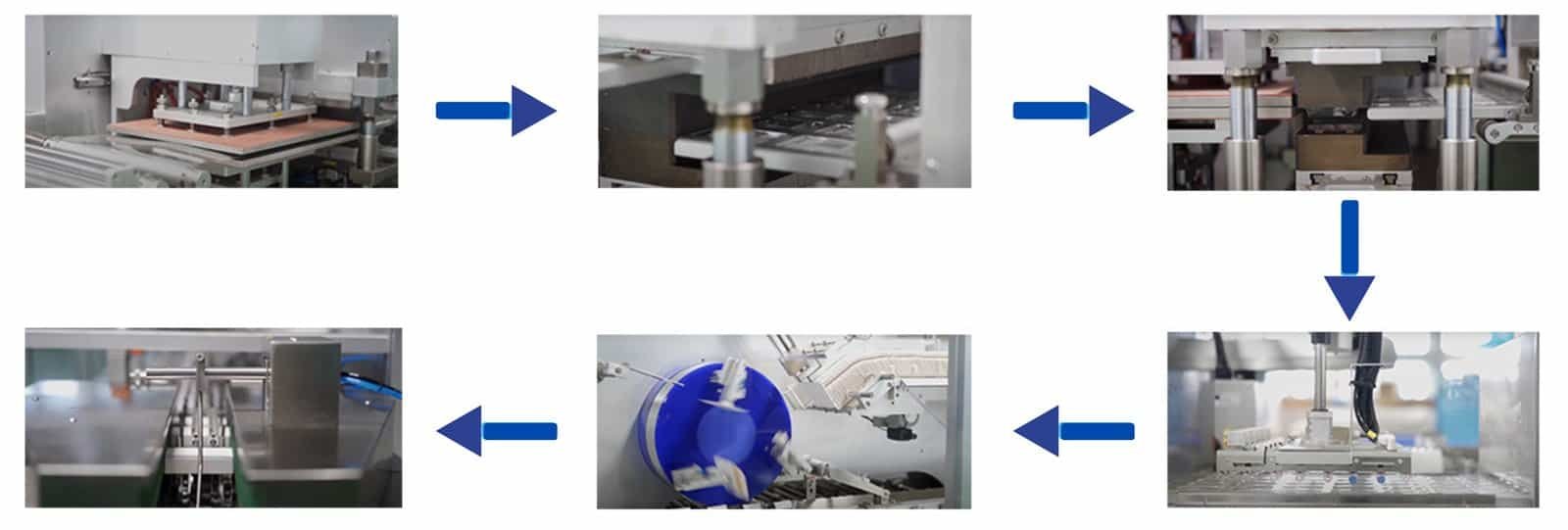

How Our Blister Packaging Production Line Works?

Process flow:

Material Handling & Feeding → Blister Forming → Product Filling → Sealing & Lamination → Cartoning → Inspection & Quality Control → Packaging & Labeling

Specifications

| Max Output: | 180cartons/min≤800bottles/min |

| Max Fomming area and deptn: | 480x160x25mm |

| Leaflet Size: | (100-200)x(100-150)mm |

| Carton size: | (70-200)x(25-100)x(14-80)mm |

| Carton Material: | 250-350g/m2 |

| Air Compressor: | 0.6-0.8Mpa≥0.8m/min |

| Leaflet material: | 50-70g/m |

| Power: | 7500Kg |

| Weight: | 380V,50Hz,16Kw |

Blister Packaging Production Line Essential Machinery

High-Speed Blister Packaging Machine

The High-Speed Blister Packaging Machine efficiently forms, fills, and seals blister packs, ensuring precise product placement and secure packaging within the blister production line.

Automatic Cartoning Machine

The Automatic Cartoning Machine automates the process of placing blister packs into cartons, ensuring efficient packaging and streamlined distribution in the blister production line.

All in One Automatic Case Packer Machine GZ-600

The GZ-600 boosts efficiency by automating tasks such as unpacking, placing box pads, packing, inserting packing lists, and sealing. It significantly increases productivity across various packaging processes.

The machine includes a data transmission interface to record and export key data. It also provides safety alerts for issues like unpacking errors, missing boxes, low compressed air pressure, and tape shortages.

Machine Details

Blister Film Device

Suction Device