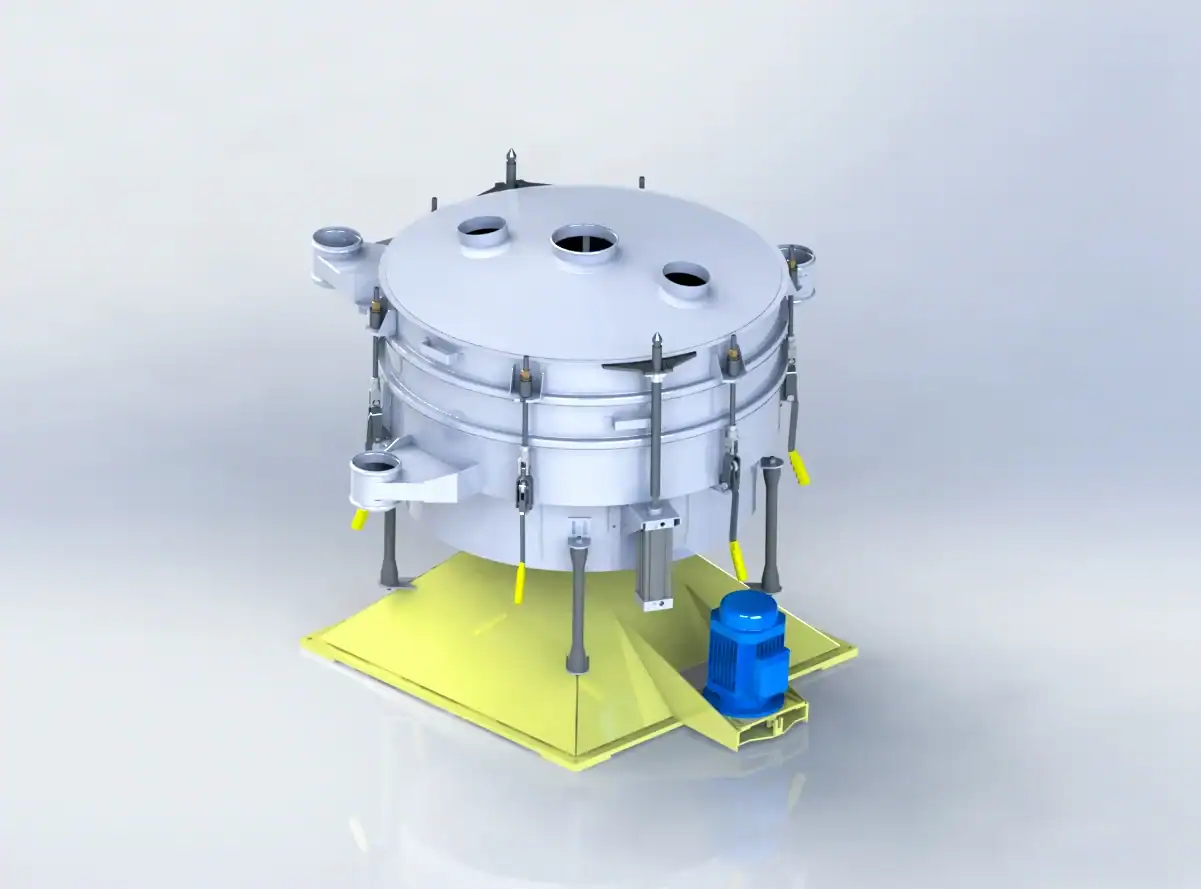

Grand SYB: Circular Swing Screen

The Grand Circular Swing Screen is designed for high-performance industrial screening applications. It utilizes a unique swinging motion, replicating manual sifting to deliver superior separation efficiency for powders, granules, and other bulk materials. Unlike traditional vibrating screens, the Grand Swing Screen’s non-linear three-dimensional motion provides more accurate particle separation. This is achieved by combining a circular motion with a parabolic throwing action that distributes materials evenly across the screening surface.

Develop Your Business with Grand

Get a Quote Today!

Interested in the Grand Circular Swing Screen? Get in touch with us now to receive more information, a customized quote, or assistance in selecting the right configuration for your needs.

Applications

The Grand Circular Swing Screen is widely used in industries requiring precise particle separation. It is ideal for:

Food Processing – Separating powders, granules, and other bulk ingredients.

Chemical Production – Screening powders and granules in various chemical processes.

Pharmaceuticals – Precise separation of active ingredients and excipients.

Metallurgy – Screening fine metallic powders and ore particles.

Recycling – Sorting particles for reuse in manufacturing processes.

Its versatility makes it an essential tool for industries requiring high precision and efficient sieving.

Technical Specifications

| Model | Diameter (mm) | Screening Area (m²) | Power Consumption (kW) | Layers | Cleaning Method |

|---|---|---|---|---|---|

| YBS600 | 600 | 0.29 | 0.25 | 5 | Rubber Ball |

| YBS1000 | 1000 | 0.71 | 1.5 | 5 | Rubber Ball |

| YBS1200 | 1200 | 1.11 | 2.2 | 5 | Rubber Ball |

| YBS1600 | 1600 | 1.83 | 2.2/4 | 5 | Rubber Ball |

| YBS2000 | 2000 | 2.62 | 2.2/4 | 5 | Rubber Ball |

Key Features

- High Capacity Output – Compared to regular vibrating screens, the Grand Circular Swing Screen delivers up to 5 times higher capacity, ensuring faster and more efficient processing.

- Accurate Separation – With a 90-95% separation accuracy, the Grand Swing Screen guarantees the highest screening precision, even for fine powders and irregularly shaped materials.

- Effective Anti-Clogging Mechanism – The advanced anti-clogging design, including an optional ultrasonic cleaning device, ensures consistent operation without material blockages.

- Low Noise Operation – Operating below 80 decibels, the Grand Swing Screen operates quietly, making it suitable for noise-sensitive environments.

- Durable Construction – Built with robust, long-lasting materials, including 304 stainless steel for direct material contact, the screen ensures long service life and minimal maintenance.

- Easy Integration – The Grand Swing Screen is designed for seamless integration into automated production lines with its dust-tight enclosure, offering both safety and cleanliness.

- Flexible Configuration – Available with up to 5 screening layers for maximum versatility in sorting various material types.

- Energy Efficient – Powered by a reliable motor that minimizes energy consumption while maintaining high throughput.

Why Choose Grand Swing Screens?

- Superior Technology – The Grand Circular Swing Screen incorporates the latest in screening technology, ensuring top-notch performance in demanding industrial applications.

- Customizable Solutions – We offer a range of models and configurations to meet specific operational needs, from small-scale operations to large industrial plants.

- Exceptional Customer Support – Our commitment to customer satisfaction extends beyond sales. With 24/7 technical support and professional installation services, we ensure your system operates at peak performance.

- Robust & Reliable – Crafted with durable materials, Grand Swing Screens are designed for maximum uptime and minimal maintenance.

- Global Reach – We have served clients across industries worldwide, providing cutting-edge solutions for screening and separation.