Grand GLA-820: The High-Speed Double-Sided Labeling Machine

In today's competitive market, efficiency, precision, and reliability are paramount. Your product's presentation is its first handshake with the customer, and a perfectly placed label speaks volumes about quality. The Grand GLA-820 Automatic Double-Sided Labeling Machine is engineered to be the heart of your production line, delivering flawless labeling at high speeds, ensuring your brand stands out for all the right reasons.

Develop Your Business with Grand

Ready to transform your production line with unparalleled speed and precision? Our team of experts is here to help you configure the perfect Grand GLA-820 labeling machine for your specific needs. Fill out the form below or contact us directly to discuss your application, and we'll provide a comprehensive, no-obligation quote. Let's build a more efficient future for your business, together.

Versatile Applications Across Industries

Daily Chemicals & Cosmetics: Perfectly suited as a Shampoo labeling machine, it effortlessly handles bottles for conditioners, lotions, soaps, and other personal care products. Its precision ensures your branding is consistent and professional on every item.

Pharmaceuticals: In an industry where accuracy is non-negotiable, the GLA-820 provides precise and secure labeling for medicine bottles, vitamin containers, and other healthcare products, with optional integration for batch coding and verification systems.

Food & Beverage: From gourmet olive oil bottles and sauce jars to flat-sided juice containers and spice boxes, this machine ensures your product looks as good as it tastes. It's built to operate in demanding food production environments.

Technical Specifications

| Parameter | Value |

|---|---|

| Model | GLA-820 Double-Sided Labeling Machine |

| Applicable Products | Flat, Square, or Oblong Bottles |

| Product Dimensions | Thickness: 20-90mm; Height: ≤300mm |

| Labeling Speed | Up to 250 bottles per minute (dependent on bottle and label size) |

| Labeling Accuracy | ±0.5mm |

| Label Stop Precision | ±0.3mm |

| Conveyor Width | 91mm |

| Overall Dimensions | (L) 3500mm x (W) 1355mm x (H) 1550mm |

| Operating Temperature | 5-45°C |

| Operating Humidity | 15-90% (non-condensing) |

Key Features of the Grand GLA-820

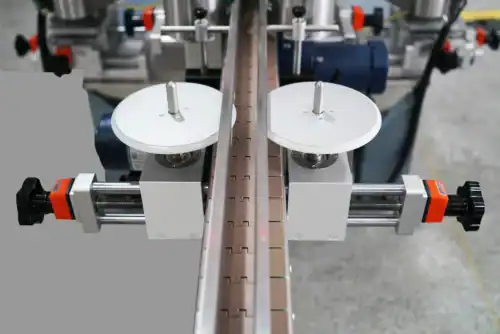

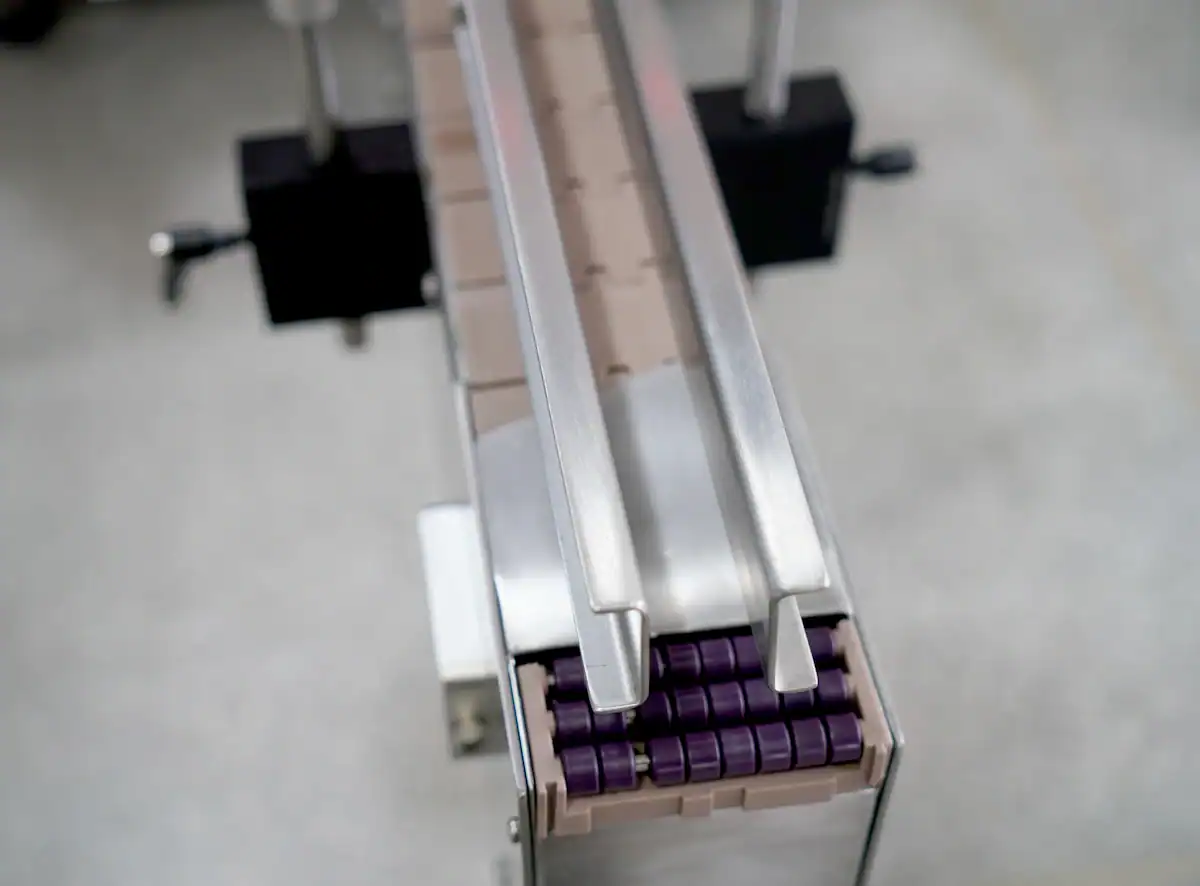

Advanced Synchronization and Stability

At the core of the GLA-820's precision is its sophisticated bottle handling system. It utilizes a flexible, symmetrical dual-chain correction mechanism to gently but firmly align each bottle before it reaches the labeling station. This ensures every container is perfectly centered, eliminating skewed or misplaced labels.

Intuitive and Intelligent Operation

Simplicity meets sophistication with the user-friendly HMI touchscreen. The interface is designed for straightforward operation, providing access to all functions and settings, complete with a rich online help system to guide operators. A standout feature is the parameter storage function, which allows you to save up to 50 unique product setups. This dramatically reduces changeover times—simply select the pre-stored recipe for a new bottle size, and the machine is ready to go without extensive manual readjustment.

Unmatched Versatility and Scalability

The GLA-820 is designed to adapt to your evolving needs. Its special elastic top belt adjustment mechanism makes switching between different bottle sizes quick and convenient. While its primary function is double-sided labeling, the machine can be equipped with optional modules, such as a wrap-around station, to handle round bottles, making it a truly multi-functional asset.

Why Choose the Grand GLA-820 Labeling Machines?

Investing in a labeling machine is a critical decision. Here’s why the Grand GLA-820 is the superior choice for businesses aiming for excellence and growth.

Experience & Expertise: We understand the challenges of modern manufacturing. The GLA-820 is the result of extensive research and engineering, designed with the user in mind. Its intuitive controls, easy changeovers, and robust construction reflect a deep understanding of production floor realities.

Authoritativeness & Performance: The machine's specifications speak for themselves. With speeds up to 250 bottles per minute and an accuracy of ±0.5mm, it is a high-performance authority in its class. Features like the dual-chain correction and synchronized top belt are not just add-ons; they are core engineering principles that guarantee superior results.

Trustworthiness & Reliability: We build machines that last. The GLA-820 is constructed with high-quality components to ensure durability and consistent performance with minimal downtime. The integrated quality control and rejection systems provide peace of mind, safeguarding your brand's reputation and ensuring compliance. This commitment to quality makes the GLA-820 a trustworthy investment for the long term.