Fluid Bed Granulator

The Fluid Bed Granulator enhances powder granulation by improving fluidity and reducing dust. It employs bottom spray granulation or coating techniques to minimize material waste while simultaneously performing spraying, mixing, granulation, coating, and drying processes.

A precise fountain fluidization ensures consistent and stable coating quality, while an upper discharge hole safeguards the equipment from potential explosions. The entire granulation and coating process is conducted within a sealed system, eliminating leakage and preventing dust from escaping.

The coating machine supports both manual and automatic operation, offering flexibility. Its design is free of blind spots, enabling fast unloading and easy cleaning, and it fully complies with GMP standards.

This versatile machine seamlessly integrates granulation, pill-making, and coating functions into one efficient system.

Contact Us

Develop Your Business with Grand

Features

- Dust-Free Production: The sealed system ensures no dust or leakage during operation.

- Multi-Functional Coating: Capable of handling both granulation and coating simultaneously.

- Stainless Steel Construction: Built entirely from food-grade stainless steel for durability and safety.

- Moving Material Bed: Provides stable fluidization for consistent coating.

How Our Solid Preparation Granulation Line Works?

Process flow chart :

Powder Feeding & Wet Granulation → Fluidized Drying → Blending → Tablet Compression → Coating (Optional) → Packaging

Specifications

| Model: | FG-15 | FG-30 | FG-60 |

| Volume: | 45L | 100L | 220L |

| Container Diameter: | 550mm | 700mm | 1000mm |

| Capacity: | 15kg | 30kg | 60kg |

| Steam Pressure: | 0.4-0.6MPA | 0.4-0.6MPA | 0.4-0.6MPA |

| Steam Consumption: | 20kg/h | 60kg/h | 120kg/h |

| Compressed Air Pressure: | 0.4-0.6Mpa | 0.4-0.6Mpa | 0.4-0.6Mpa |

| Compressed Air Consumption: | 0.6m³/min | 0.6m³/min | 0.9m³/min |

| Air Blower: | 3Kw | 5.5Kw | 11Kw |

| Electric Heating Power: | 12Kw | 21Kw | 30Kw |

| Model | FG-200 | FG-300 | FG-600 |

| Volume: | 670L | 1000L | 1500L |

| Container Diameter: | 1400mm | 1600mm | 1800mm |

| Capacity: | 200kg | 300kg | 500kg |

| Steam Pressure: | 0.4-0.6MPA | 0.4-0.6MPA | 0.4-0.6MPA |

| Steam Consumption: | 180kg/h | 310kg/h | 400kg/h |

| Compressed Air Pressure: | 0.4-0.6Mpa | 0.4-0.6Mpa | 0.4-0.6Mpa |

| Compressed Air Consumption: | 1.1m³/min | 1.1m³/min | 1.5m³/min |

| Air Blower : | 22Kw | 30Kw | 45Kw |

| Electric Heating Power: | 87Kw | 163Kw | 185Kw |

Machine Details

Warehouse

Granulator details

Granulator Cover

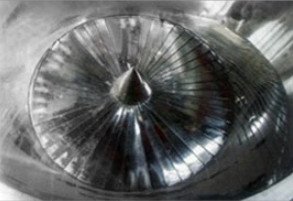

Fluidized bed

Stainless Steel Construction

FAQS

Here are some FAQs

Related Articles