Fully automatic high-speed tablet press GP-15

Grand GP-15 tablet pressing process adopts secondary pressure forming. The pre-press wheel and the main press wheel are adjusted independently, and the large-size press wheel makes the produced tablets get the best pressing time

The work flow of the tablet press, including filling, quantification, pre-pressing, main pressing, and other processes.

New high-precision punching plate preparation process, thereby controlling the quality of the finished tablet and increasing the speed

Submit detailed requirements immediately

Electronic control part and auxiliary machine

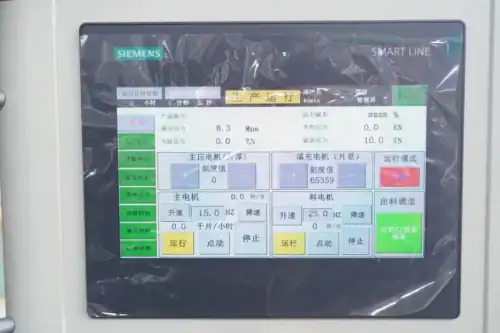

GP series automatic high-speed rotary pill presser is installed with the special operation control system for this series of models. The system provides an intuitive display of user-specific data, and a large color touch screen makes all production data obvious.

It can be easily combined with Grand Rotary Sieve Machine, Vacuum Loader and other auxiliary machines to form an efficient small production line

High-speed tablet press GP-15 Specifications

| Parameter | Value |

|---|---|

| Turntable punching module (vice) | 15 |

| Max. working main pressing (KN) | 100 |

| Max. tabletting diameter (mm) | 25 |

| Max. special-shaped long shaft size (mm) | 25 |

| Pre-pressure (KN) | 12 |

| Max. filling depth (mm) | 20 |

| Tablet thickness range (mm) | 0.5~10 |

| Max. tablet yield (Tablet/h) | 65000 |

| Machine size (mm) | 900*720*1500 |

| Weight of machine (Kg) | 675 |

| Power requirements | 380V 50Hz 8.0 kW |

Main features of equipment Rotary Tablet Press GP-15

The frame of the body is made of cast iron, and the machine runs more smoothly

Combined upper guide rail design, easy to disassemble, maintenance, replacement, use double-sided lifting guide rail, punch force uniform, long life

The centralized lubrication system (dry oil lubrication system, thin oil lubrication system and circulating lubrication system) provides enough lubricant to each lubrication part through automatic control to ensure the safe operation of the machine

Large plate hole processing technology

The processing technology of punching die holes of other manufacturers is normally cut by boring machine, because this processing method leads to the poor finish of the middle plate hole, and the later stage and the middle die can only be interference fit, resulting in the difficulty of entering and exiting the hole of the middle die.

Grand's middle die holes in the boring machine cutting, and then each hole grinding processing, at the same time with the coordinate detection equipment for hole detection, to ensure the finish and accuracy of the hole. The processing cost is much higher. The punch plate is the most core workpiece of the tablet press, and its accuracy can fully represent the overall accuracy of the high-speed tablet press.

For example, the coaxiality of the upper, middle and lower punching directly affects the quality of the sheet and the life of the die; The runout of the end face of the middle punching plate directly affects the powder leakage and yield.

Change the mold directly by hand

Grand's tablet press, without borrowing any tools, complete the disassembly of the mold by hand. The design and development ensure that the medium die hole of the plate of the high speed tablet press will not be deformed for a long time.

Other manufacturers because of borrowing tools to knock on the mold to complete the assembly and disassembly, but borrowing tools to knock on the mold is easy to extrude metal chips, and labor intensity, low production efficiency, waste a lot of time, while years of knocking on the mold, so that the hole becomes elliptical, precision loss, up and down punch with the mold precision problems.

Grand's freehand punching function can save at least 2 hours each time the mold is replaced, the mold is replaced once a week, calculated according to 50 weeks a year, then a year can save 100 hours in the mold replacement, such as the saved time is used for production, and the output of 150,000 pieces per hour can be increased by 15 million pieces, estimated according to Gliclazide sustained release tablets. It can increase sales by more than 10 million yuan per year, which is excellent value for money.

Pill Presser Details

The above pictures show the tablet press rotary tower, the variety of mold options and convenient customization, and the Siemens touch screen.

Why Choose Grand as Your Tablet Press Supplier?

- ✅Proven Track Record

Grand has installed over 1,000 rotary tablet machines worldwide. Our clients report average uptimes above 95%. ✅Comprehensive Support

From on‑site commissioning to operator training and 24/7 technical assistance, Grand ensures your pill machine runs smoothly.✅Customized Solutions

Tailor tooling, process validation, and documentation (IQ/OQ) to meet your unique regulatory requirements.✅Quick maintenance

Tablet Press Maintenance: A Pill Press Lubrication Guide