Liquid Capsule Filling Machine NYF-300

The high precision ceramic pumps and servo motor liquid adding systems accurately control the loading differences to at ±2% level, while the capsule feeder with a vacuum positioning system gives you a loading rate over 99%. You’ll see the capsules filling one after the other before your eyes and your fingers do all the work.

Contact Us

Features

Sealed for Freshness

The sealing mechanism features a servo motor to achieve the ultra-precise adjustment for the tightest sealing layer with the sealing liquid. The sealing tank is equipped with a heater to maintain the temperature, ensuring the viscosity of the glue is at the designated point. Your small-size capsules remain sealed during packaging, shipment and until you use them.

Intuitive Controls

Due to a simple human-machine interface control system and straightforward instruction system of the NYF-300, anyone can operate it. When the capsules or materials reach a critically low level, you will be automatically alerted to refill them.

Efficient Design

The drying and curing mold adopts a hanging and free-rotating structure to enable quick and simple disassembly and cleaning. The sealed sealing tank prolongs the glue adding cycle. With such thoughtful design, you'll spend less time on maintenance.

Specifications

| Humidity: | 40%--55% |

| Output: | 18000 capsules/hour |

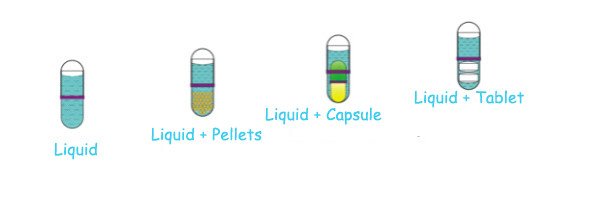

| Filling Materials: | Capsules Solution, Suspension, Microemulsion |

| Mold Holes: | 6 holes |

| Applicable Capsules: | 00-4# gelatin, vegetable capsules |

| Filling Accuracy: | ±2% |

| Positive Pressure: | 20Kpa |

| Negative Pressure: | 24Kpa |

| Maximum flow: | 180m3/h |

| Indoor Temperature: | 20℃ |

| Noise: | ≤75dBA |

| Power Supply, Voltage: | 380V/220V 50Hz |

| Total Power: | 9KW |

| Machine Weight: | 2300KG |

| Compressed Air Pressure: | 0.6-0.7Mpa |

| Dimensions: | 3800*900*1900MM |

Machine Details

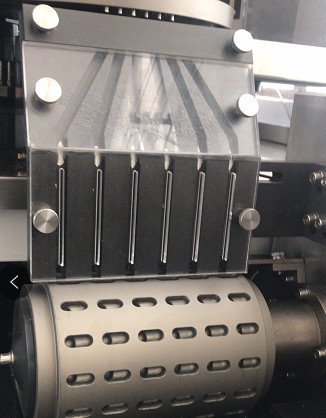

Capsule Board

Capsule Plate

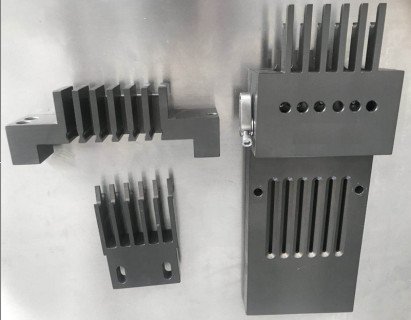

Fork Capsule Plate