Pharmaceutical Packaging Line-Pharmaceutical Counting Line for Tablets & Capsules

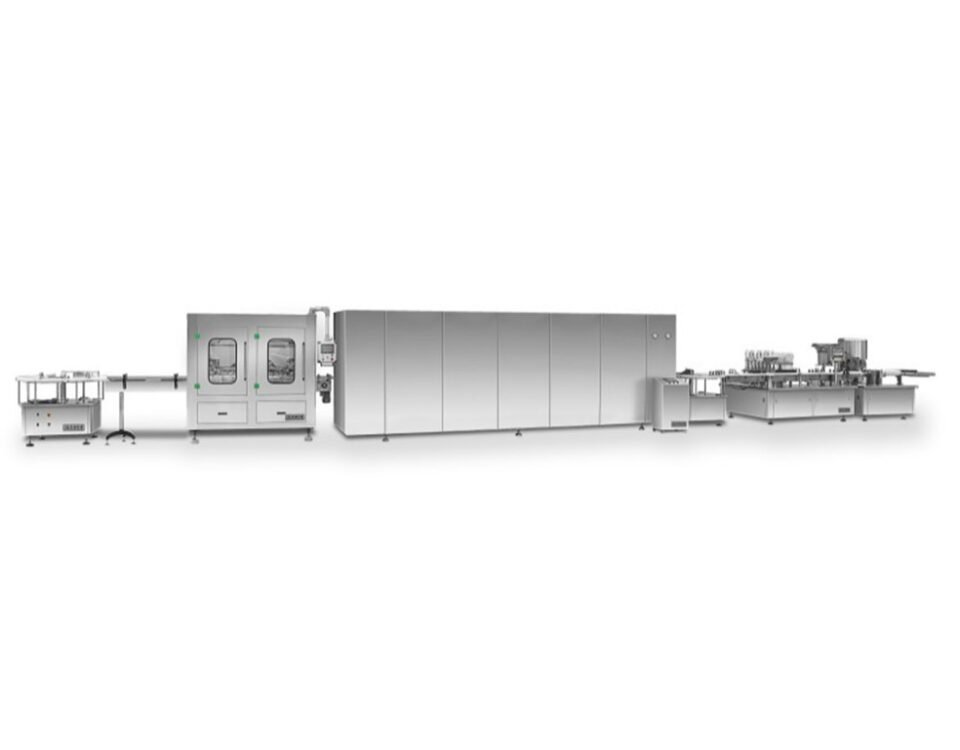

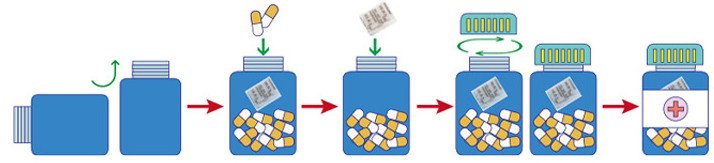

Boost your production with our complete Pharmaceutical Counting line. We engineer our integrated systems for maximum speed, pinpoint accuracy, and unwavering reliability. This turnkey Tablet counting line takes you from empty bottles to shelf-ready products seamlessly, minimizing labor and eliminating errors. It’s the smart solution for modern pharmaceutical and nutraceutical packaging.

Key Features of Our Pharmaceutical Counting Line

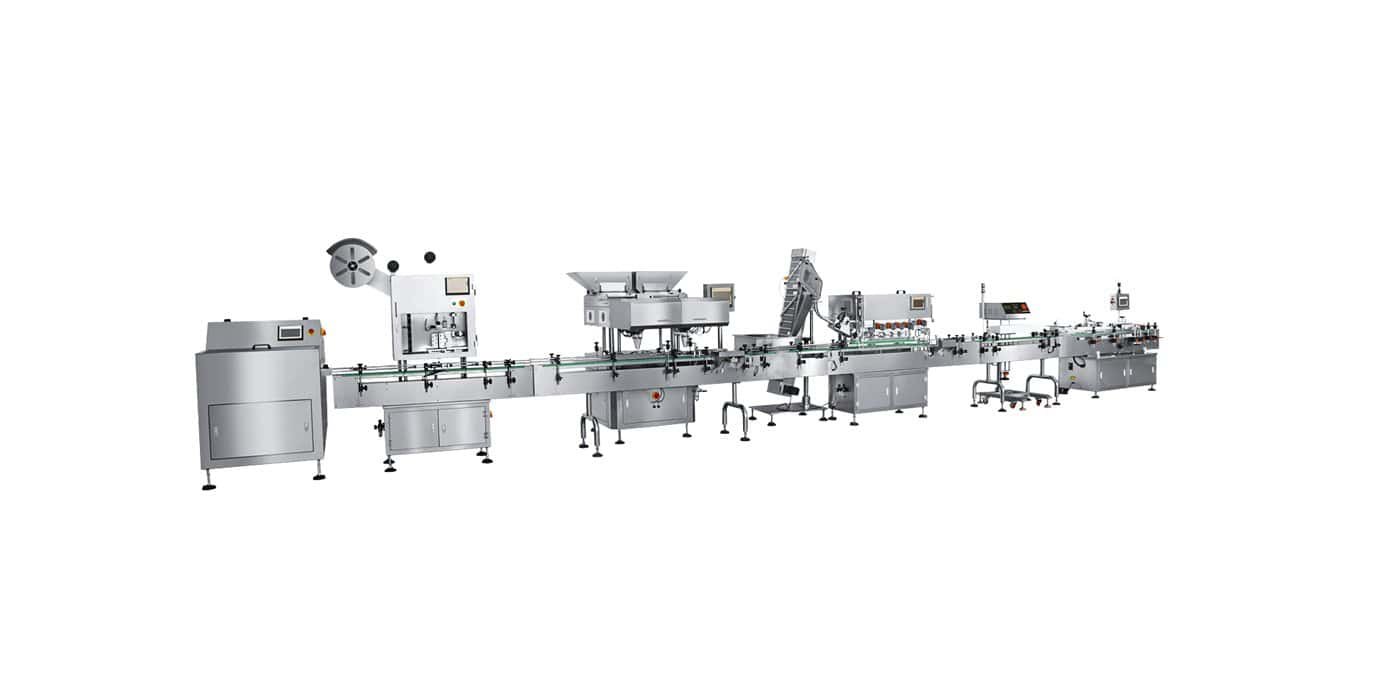

Fully Customizable & Modular Design Your product is unique. Your production line should be too. We tailor every Counting line to your specific bottle sizes, product shapes, and output goals. Our modular design allows you to easily add or remove stations, like a desiccant inserter or paper inserter, as your needs evolve.

Unmatched Product Versatility Don't limit your capabilities. Our Capsule counting line is built for flexibility. It expertly handles tablets of any shape, hard capsules, softgels, pills, and even non-pharma products like chewing gum and candies with ease.

Precision Counting Technology Accuracy is everything. At the heart of our line is a high-speed, multi-channel Counting Machine. Advanced infrared sensors and anti-dust technology guarantee near-perfect counting accuracy, eliminating costly product giveaway and ensuring dosage compliance.

Why Choose Grand for Your Counting Line?

Decades of Industry Expertise We don't just sell machines; we provide solutions. With decades of experience, we understand the challenges of the pharmaceutical industry. We build our counting lines to meet the highest standards of quality and performance.

Uncompromising Quality and Reliability Our lines are built to last. We use high-grade materials and world-class components to ensure your investment is reliable, durable, and productive for years to come. We stand behind the quality of every machine we build.

We Are Your Production Partner Your success is our success. We work closely with you to understand your goals. From initial design to final installation, we act as your dedicated partner, ensuring your Tablet counting line delivers exactly what you need.

The Grand Advantage: A Better Tablet Counting Line

True Integration vs. Piecemeal Solutions Our complete Counting line is engineered as one cohesive system. You get a single point of contact and guaranteed compatibility. Avoid the headaches and hidden costs of integrating mismatched equipment from multiple vendors.

Superior Counting Machine Technology Our advanced Counting Machine sets us apart. It delivers superior accuracy at high speeds, even with difficult-to-handle or dusty products. Many standard counters simply cannot match its precision and reliability.

Faster Installation and Onboarding Get to market faster. Our experienced technicians manage a smooth and efficient installation process. We get your Pharmaceutical counting line up and running quickly, with comprehensive training to minimize your learning curve.

Line Details

Service and Support You Can Count On

True Integration vs. Piecemeal Solutions Our complete Counting line is engineered as one cohesive system. You get a single point of contact and guaranteed compatibility. Avoid the headaches and hidden costs of integrating mismatched equipment from multiple vendors.

Superior Counting Machine Technology Our advanced Counting Machine sets us apart. It delivers superior accuracy at high speeds, even with difficult-to-handle or dusty products. Many standard counters simply cannot match its precision and reliability.

Faster Installation and Onboarding Get to market faster. Our experienced technicians manage a smooth and efficient installation process. We get your Pharmaceutical counting line up and running quickly, with comprehensive training to minimize your learning curve.

The Bottle Unscrambler in a pharmaceutical packaging line efficiently organizes and aligns randomly oriented bottles, ensuring a smooth and continuous flow for downstream filling and capping processes.

Bottle Unscrambler

Max output: | 150 bottles/Min |

Bottle Size: | 15~650ml |

Voltage/Frequency: | AC220V/50-60Hz 1P |

Power: | 0.50KW |

Air Pressure: | 0.3~0.6Mpa |

Air consumption | 0.4m³/h |

Overall size | 1050x1530x1205mm |

Net Weight | 337Kg |

The Grandpack Labeling Machine in a pharmaceutical packaging line precisely applies labels to containers, ensuring accurate product identification, regulatory compliance, and brand representation.

Labeling Machine

Max Output: | 180 bottles/Min |

Bottle Size: | 15~650ml |

Label Size: | L:20-250mm/ W:20-75mm |

Voltage/Frequency: | AC220V/50-60Hz 1P |

Power: | 2.0KW |

Air Pressure: | 0.3~0.6Mpa |

Air Consumption: | 0.4m³/h |

Overall Size: | 1950x1060x1300mm |

Net Weight: | 237Kg |

Screw Capper

Max. Output: | 150 bottles/min |

Bottle size: | 15~650ml |

Cap size | φ15-65mm / H 8-30mm |

Voltage/Frequency: | AC220V/50Hz 1P |

Power: | 1.5Kw |

Air Pressure: | 0.3~0.6Mpa |

Air consumption: | 0.3m³/h |

Dimension(LxWxH): | 2600x1060x1950mm |

Net Weight: | 613Kg |

In the pharmaceutical packaging line, the Grand Screw Capper plays a vital role. Its main function is to quickly and accurately tighten the bottle caps for the bottles containing the medicines to ensure the sealing and safety of the medication.

We can also customize different models to suit your needs, including pharmaceutical packaging, daily chemicals, and food.

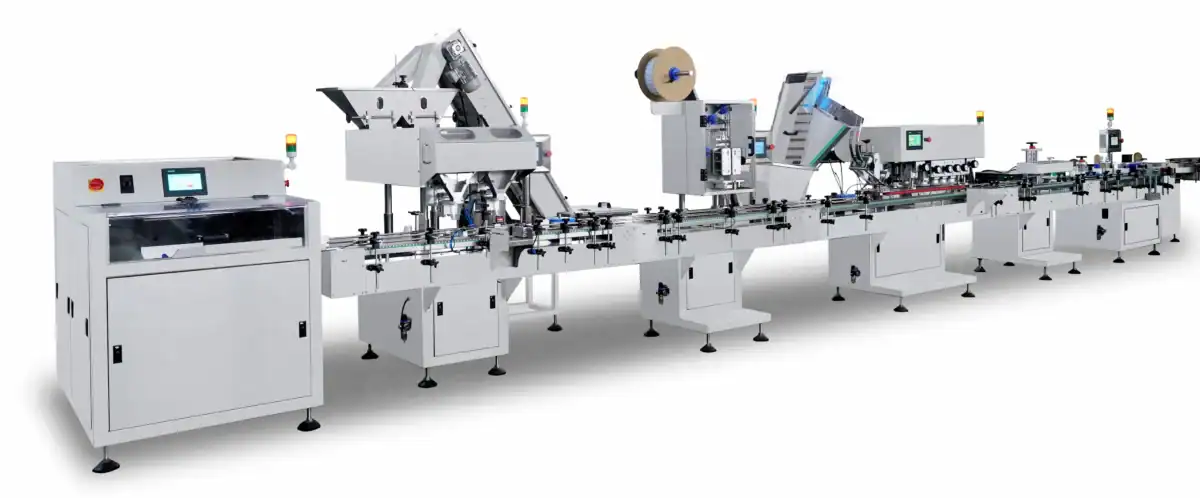

High-Speed Electric Counting and Filling Machine GDS-16D is a high-speed, 16-channel counting and filling machine designed for precise, efficient tablet and capsule filling in pharmaceutical production.

Featuring advanced dust collection and user-friendly controls for optimal accuracy and reliability.

Max Output: | 180 bottles/Min |

Bottle Size: | 15~650ml |

Label Size: | L:20-250mm/ W:20-75mm |

Voltage/Frequency: | AC220V/50-60Hz 1P |

Power: | 2.0KW |

Air Pressure: | 0.3~0.6Mpa |

Air Consumption: | 0.4m³/h |

Overall Size: | 1950x1060x1300mm |

Net Weight: | 237Kg |

Aluminium Foil Induction Sealer

Max Output: | 150 bottles/Min |

Bottle Size: | 15~650ml |

Bottle neck size: | 20-70mm |

Voltage/Frequency: | AC220V, 50/60Hz 1P |

Power: | 4.0KW |

Induction head size: | 450x200x90mm |

Net Weight: | 100Kg |

Aluminum Foil Induction Sealer uses the principle of electromagnetic induction to heat the aluminum foil sealing pad and firmly bond it to the bottle mouth, forming a safe and reliable sealing layer to ensure the sealing and safety of the medicine.

FAQS

Here are some FAQs

Contact Us