Pharmacy Pill Packaging Machine

This machine is designed to package tablets, granules, and capsules in the pharmaceutical industries.

Videos

Specifications

| Warranty: | 1 Year |

| After-sales Service: | Whole Life After-Sale Service |

| Punches Frequency: | 10-35 Times/Min |

| Capacity (80mm*57mm Sheet): | 2400 Plates Per Hour |

| Travel Range: | 20-80mm (Optional) |

| Air Pressure: | 0.4-0.6 MPa |

| Main Motor Power: | 0.75kw |

| Total Power: | 220V 50Hz 1.8 Kw (Customized Available) |

| PVC Material: | 0.15-0.50*80mm |

| PTP Alu Foil: | 0.02-0.035*80mm |

| Dialysis Paper: | 50-100g*80mm |

| Noise Index: | Less than 75dBA |

| Machine Dimension: | 2500*800*1780mm |

| Machine Weight: | 450Kg |

Machine Details

Rolling film device

Can hold 25kg blister film roll

PLC Display

More than 25 languages system support

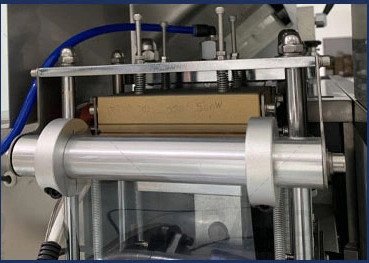

Film Roll Bar

Slow rolling without tearing the blister

FAQS

Here are some FAQs

1What types of products can this machine package?

The Pharmacy Pill Packaging Machine is ideal for packaging tablets, granules, and capsules.

This versatility makes it a valuable asset in pharmaceutical manufacturing.

This versatility makes it a valuable asset in pharmaceutical manufacturing.

2How does the machine ensure product quality during packaging?

The machine's slow rolling film device minimizes tearing, ensuring product integrity.

This careful handling preserves the quality of the packaged items.

This careful handling preserves the quality of the packaged items.

3Is the machine suitable for international operations?

Yes, it features a PLC display that supports more than 25 languages,

making it adaptable for use in various countries and regions.

making it adaptable for use in various countries and regions.

4What is the machine's production capacity?

The machine can produce up to 2400 plates per hour,

making it highly efficient for large-scale production demands.

making it highly efficient for large-scale production demands.

5Does the machine offer customization options?

Absolutely, the machine's power and travel range can be customized to meet specific needs.

This flexibility ensures it can be tailored to different production requirements.

This flexibility ensures it can be tailored to different production requirements.

6How does the machine manage noise levels?

The machine operates with a noise index of less than 75 dBA,

which ensures a quieter working environment, enhancing operator comfort.

which ensures a quieter working environment, enhancing operator comfort.