Horizontal Ribbon Blade Mixer: The Ultimate Solution for Powder Mixing

Precision, Efficiency, and Uniformity for Industrial Applications

In the world of industrial processing, achieving a homogenous blend is the foundation of quality manufacturing. The Grand WLDH Series Ribbon Blade Mixer stands as a market-leading solution designed to handle the complex mixing needs of the pharmaceutical, food, chemical, and building material industries.

Whether you are blending dry powders, granules, or mixing liquids into viscous pastes, our machine delivers consistent results. Often referred to as a Horizontal screw mixer, this equipment is engineered to reduce mixing time while ensuring that every particle is evenly distributed.

Key Features of the WLDH Ribbon Mixer

1. Superior Mixing Homogeneity

The carefully calculated angle of the ribbon blades ensures there are no "dead zones" within the U-shaped container. This results in a coefficient of variation (CV) that meets strict pharmaceutical and food safety standards.

2. Versatile Discharge Options

We offer flexibility to match your facility’s infrastructure.

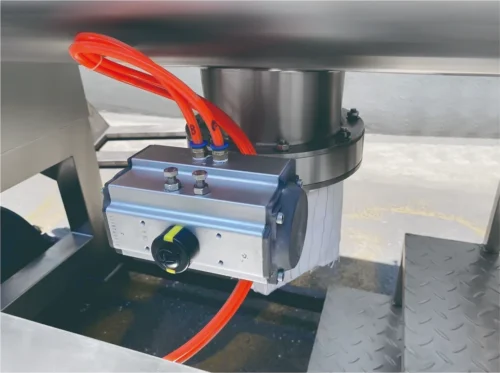

Pneumatic Butterfly Valve: For automated lines, ensuring quick and clean discharge.

Manual Butterfly Valve: For cost-effective, manual control.

Turn-off Fan Discharge: Ideal for minimizing residue.

3. Robust Construction

The entire machine is constructed from high-grade Stainless Steel (304 or 316L available). The interior is polished to a mirror finish to prevent material adhesion, making it a true sanitary Horizontal screw mixer.

4. Enhanced Safety Features

Worker safety is paramount. Our units come equipped with a robust Guardrail (safety grid) beneath the cover. This prevents operators from reaching into the moving parts while still allowing them to monitor the process or add minor ingredients safely.

5. Liquid Spraying System (Optional)

Do you need to add binders, flavors, or oils to your powder? We can equip the top cover with spray nozzles to atomize liquid additives, ensuring they are evenly coated onto the granules without forming clumps.

Develop Your Business with Grand

Detailed Machine Configuration

To understand why the Grand Ribbon Blade Mixer performs so well, we must look at the details shown in our technical breakdown.

Pneumatic Cylinder Cover: For larger models or automated setups, we offer pneumatic lifting for the cover, reducing physical strain on operators.

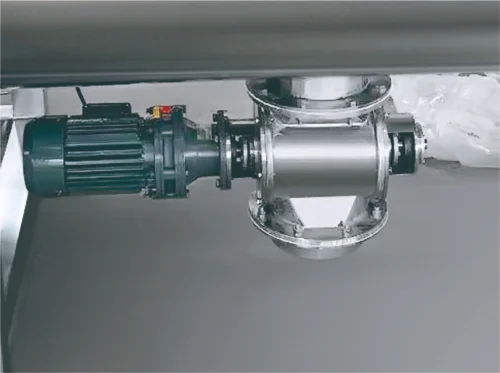

The Drive System

Powering the Ribbon Mixers is a high-efficiency motor and gear reducer combination.

Models WLDH-0.1 to WLDH-0.5: Direct motor drive for compact efficiency.

Models WLDH-1 to WLDH-15: Heavy-duty drive systems capable of handling high-torque starts, even when the mixer is fully loaded.

Guardrail

Turn off the fan and discharge the material

Cylinder flip cover

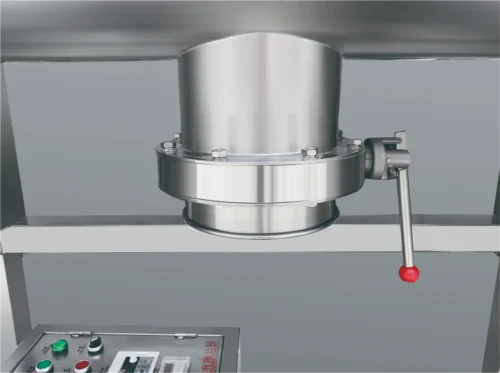

Manual butterfly valve

Pneumatic butterfly valve

Specifications

| Model | Full Volume (m³) | Loading Coefficient | Motor Power (kw) | Dimensions (L×W×H mm) | Weight (kg) |

| WLDH-0.1 | 0.1 | 0.4–0.8 | 2.2 | 1190 × 740 × 770 | 330 |

| WLDH-0.3 | 0.3 | 0.4–0.8 | 5.5 | 2030 × 630 × 980 | 720 |

| WLDH-0.5 | 0.5 | 0.4–0.8 | 7.5 | 2320 × 730 × 1130 | 980 |

| WLDH-1 | 1 | 0.4–0.8 | 11 | 2800 × 920 × 1320 | 1700 |

| WLDH-1.5 | 1.5 | 0.4–0.8 | 15 | 3180 × 1020 × 1550 | 1800 |

| WLDH-2 | 2 | 0.4–0.8 | 15 | 3310 × 1120 × 1640 | 2100 |

| WLDH-3 | 3 | 0.4–0.8 | 18.5 | 3750 × 1290 × 1820 | 3000 |

| WLDH-4 | 4 | 0.4–0.8 | 22 | 4200 × 1400 × 1990 | 3980 |

| WLDH-5 | 5 | 0.4–0.8 | 22 | 4220 × 1500 × 2100 | 4620 |

| WLDH-6 | 6 | 0.4–0.8 | 30 | 4420 × 1610 × 2260 | 6180 |

| WLDH-8 | 8 | 0.4–0.8 | 37 | 4700 × 2150 × 2470 | 8200 |

| WLDH-10 | 10 | 0.4–0.8 | 45 | 5520 × 2960 × 2720 | 8920 |

| WLDH-12 | 12 | 0.4–0.8 | 45 | 5720 × 3010 × 2840 | 9520 |

| WLDH-15 | 15 | 0.4–0.8 | 55 | 5840 × 3540 × 2940 | 9950 |

Why Choose Grand Machinery?

1. Tailored to Your Scale We don't believe in "one size fits all." As seen in our technical parameters, we offer a massive range of sizes.

Lab Scale: Our WLDH-0.1 (100L) is perfect for R&D and small batch testing.

Industrial Scale: Our WLDH-15 (15,000L) is a beast designed for massive production output.

2. Expertise in Customization We understand that a chemical plant has different needs than a bakery. We can customize the Horizontal screw mixer with:

Heating or cooling jackets for temperature-sensitive products.

Explosion-proof motors for hazardous environments.

Vacuum feeding systems to keep your workshop dust-free.