Soft Gel Capsule Making Machine RJWJ-115/200C/300C

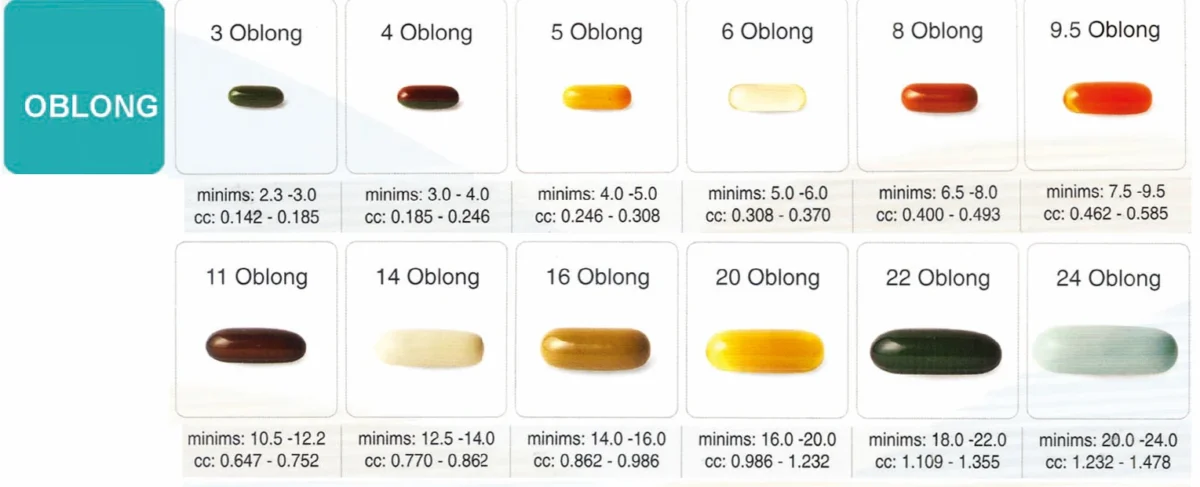

The Soft Gel Capsule Producing Machine precisely injects oils, suspensions, and pasty materials into capsules, forming softgel capsules in various sizes, shapes, and colors.

Choose your softgel product

Develop Your Business with Grand

Features

Rapid Disintegration: Softgel capsules disintegrate quickly, making them easy to swallow and resistant to oxidation.

Convenient Storage and Use: These capsules are easy to store and handle, contributing to their growing popularity.

High Productivity: Softgel encapsulation is favored by manufacturers across various industries, including pharmaceuticals, health products, cosmetics, and paintball, due to its high productivity.

Precision and Quality: The machine ensures precise filling, consistent quality, and a high finished product rate, making it a reliable choice for large-scale production.

| Weight(kg): | 960 |

| Filling Accuracy: | 1 (%) |

| Power: | 6Kw |

| Packing Volume: | 5 (L) |

| Subpackaging Capacity: | 1 (ml) |

| Applicable Industries: | Daily chemicals, medicine |

| Filling Speed: | 10000 to 150000 |

| Packing Type: | Capsules |

Why Choose Us?

Optimized designed mould is made of high quality aviation alloy materialby high precision numerical control process to ensure the mould's service life.

Advanced process and assembly technics make the complete appliance qualitystabilization , high working rate, and good shape pill.

Adopt automatic system project of supplying capsule and material to reduceworkers' labor intensity and improve the working environment, which accordswith the requirement of GMP.

The liquid level in the gelatin box is fixed automatically in the constant position,and the centigrade mater display the thickness of rubber, which is easy andaccurate in adjustment.

The power of main motor is 1.5KW, which can avoid the phenomenon ofinsufficient driving power when the content is rather thick.( Tack 200 model forexample). Adopt the nonpoisonous materials to human body or now droppingmatters into medicine liquid in this machine and medicine liquid,and the touchingparts for gelatin.

Precautions

✔In the self-tuning process, in order to prevent the sprinkler body from being burned, the gelatin skin should be passed through slowly to absorb the heat of the sprinkler body and protect the sprinkler body.

✔The length of the self-tuning time generally varies with the system environment, and the general time is about 10 minutes to 45 minutes.

✔After self-tuning, the temperature controller will store the control parameter values, and the future production does not need to go through this stage. After that, if the control deviation is found to be relatively large, it can be re-adjusted.