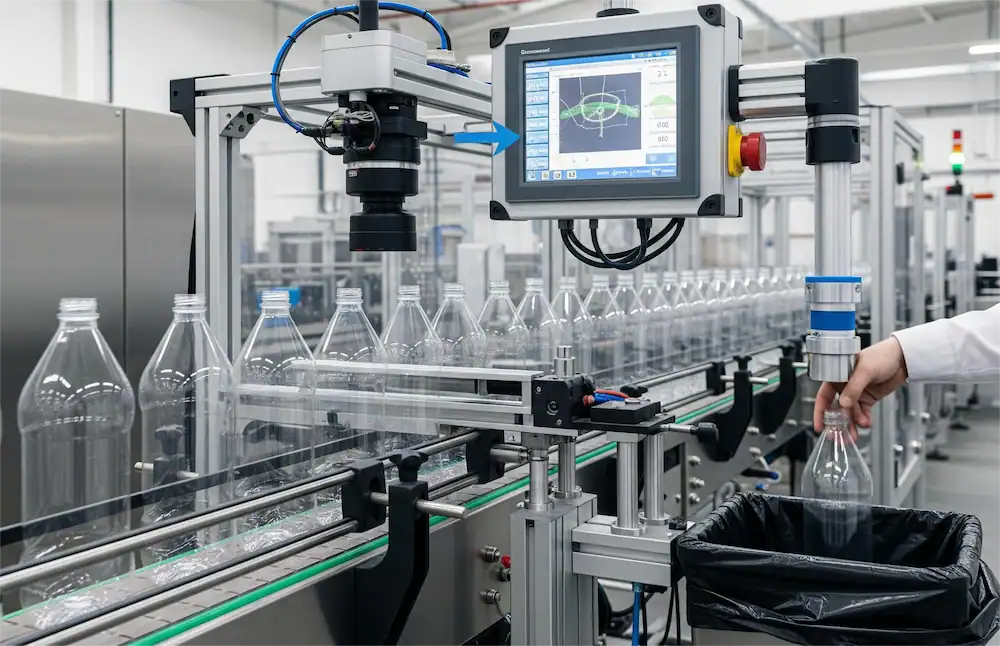

GV1900: The Ultimate Automated Inspection Equipment for Transparent Bottles

Transparent bottles look clean. But they hide flaws. Reflections and refractions conceal critical defects like micro-cracks, contamination, and deformities. Manual inspection is slow and unreliable. Standard cameras are easily fooled by glare. These hidden problems can lead to leaks, contamination, and costly product recalls.

The GV1900 is the answer. It is a premium piece of automated inspection equipment powered by Grand's proprietary AI. We designed this AI inspection system to master the unique challenges of transparent bottle inspection. Its multi-camera array and advanced AI engine provide a complete 360° analysis of every bottle, inside and out. Find and remove every flaw before you fill.

Application Scenarios: Quality Control Where It Counts

Integrate the GV1900 at the most critical points in your production process.

In-Line on Molding Lines: Install the GV1900 directly after your injection or blow molding machines. It provides real-time, 100% online inspection, instantly identifying and rejecting defective bottles. This gives you immediate feedback to optimize your molding process.

Final Inspection Before Filling: Place the GV1900 as the final gatekeeper before your filling and capping stations. It intercepts bottles with critical defects like mouth deformities or micro-cracks, preventing leaks and contamination after the product is filled.

Total Form Compatibility: The system is designed to handle all your packaging needs. It is fully compatible with cylindrical bottles, square bottles, and other custom or irregular shapes.

Develop Your Business with Grand

Key Advantages of the GV1900 System

1. 60° Flaw Detection with AI Perspective Imaging

We see what others miss. The GV1900 uses a circular array of 16 high-resolution cameras. This layout, combined with polarized and multi-angle light sources, eliminates reflective interference. Our AI then fuses this data to accurately identify internal material buildup and tiny fusion holes with a precision of 0.2mm².

2. Intelligent Defect Classification. Eliminate False Rejects.

Stop rejecting good products. Our deep learning model is smart. It automatically distinguishes between intentional design texture and a genuine defect, such as a scratch. This intelligence drops the false rejection rate to less than 0.01%, saving you money and material. You can also customize defect standards to implement AQL quality-level control.

3. High-Speed, Synchronized Inspection

Quality control should never be a bottleneck. The GV1900’s multiple cameras process images in parallel. This allows for inspection speeds of 100-200 bottles per minute, depending on bottle size. It responds to sorting commands in milliseconds, seamlessly integrating with your high-speed line.

4. Zero-Debug Flexibility. Changeovers in 5 Minutes.

Time is money. Our "one-click" changeover system is revolutionary. Select a new bottle type from the pre-programmed library.The GV1900 adapts its parameters instantly. Switch between different bottle specifications (50ML to 1000ML) in just 5 minutes, with no complex debugging required.

5. Self-Cleaning Optics for Maximum Uptime

We built the GV1900 for the real world. The optical system features an anti-dust and anti-fog design. It performs reliably even in humid or dusty environments, reducing maintenance frequency and maximizing your production uptime.

Industry Comparison: GV1900 vs. The Alternatives

| Feature | GV1900 AI System | Standard Vision System | Manual Inspection |

|---|---|---|---|

| Reflection Handling | Excellent. Multi-camera array and polarized light eliminate glare and distortion. | Poor. A single camera is easily blinded by reflections, leading to missed defects. | Poor. Inconsistent; inspectors easily get eye fatigue from glare. |

| Defect Coverage | Complete 360°. Sees internal and external flaws, including micro-defects. | Limited. Typically only checks 1-2 sides. Misses internal and subtle flaws. | Incomplete. Cannot reliably see micro-cracks or precise deformations. |

| Speed & Consistency | Very High. Up to 200 bottles/min with 99.9% accuracy, 24/7. | High Speed, Low Trust. Fast but often has high rates of false accepts or rejects. | Very Slow. 20-30 bottles/min with declining consistency and accuracy. |

| Changeover Time | < 5 Minutes. One-click, software-based changeover. | Hours. Requires physical adjustments, lighting changes, and expert programming. | Minutes. Fast to adapt, but requires retraining for new defect standards. |

| Accuracy | Exceptional (99.9%). AI differentiates textures from true defects. | Moderate. High false positive rate on complex or textured bottles. | Low. Highly subjective and prone to human error. |

Why Choose the GV1900?

The GV1900 is more than automated inspection equipment; it is a guarantee of quality that protects your brand and your bottom line.

Prevent Problems Before They Start. By inspecting empty bottles, you eliminate flaws at the source. This prevents wasting valuable product in faulty containers and avoids the huge costs of a product recall.

Trust in Flawless Data. The powerful NVIDIA AI core and 16-camera system deliver objective, reliable, and traceable quality data for every single bottle. You can finally move beyond "good enough" to data-driven perfection.

Automate with Confidence. The GV1900 is built for industrial reality. From its high-speed tracking to its self-cleaning optics and simple changeovers, it is designed to make your journey to full automated quality control smooth and profitable.

Frequently Asked Questions

1. How does the GV1900 actually overcome the problem of reflections on transparent bottles?

It uses a combination of smart hardware and software. The 360-degree ring of 16 cameras views the bottle from every possible angle simultaneously. We combine this with polarized light filters and multi-angle light sources that actively cancel out glare. The AI then stitches these clean images together to create a complete, reflection-free view of the bottle, inside and out.

2. We produce over 20 different bottle SKUs. Is it difficult to switch the machine from one to another?

No, it is incredibly easy. This is a key advantage of the GV1900. Once a bottle profile is saved in the system library, you can switch to it with a single click on the touchscreen. The entire process of loading the new parameters and being ready to run takes less than five minutes, with no manual adjustments or reprogramming needed.

3. What specific types of defects can the GV1900 find?

It is programmed to find all critical packaging flaws. This includes surface defects like dirt, black spots, and scratches. It also finds molding defects like material shifts (uneven thickness), burrs, notches, and tiny fusion holes. Crucially, it inspects the bottle mouth and seal surface for deformation or micro-cracks that could cause leaks.

4. What makes your AI "intelligent"? How does it avoid rejecting bottles with acceptable marks like logos or textures?

Our deep learning AI is trained on thousands of images. It learns to understand the "good" parts of a bottle, including embossed logos, mold lines, or decorative textures. It then specifically searches for anomalies that deviate from this perfect standard. This allows it to ignore acceptable patterns and only flag true defects, resulting in a very low false positive rate (<0.01%).

5. Can the GV1900 keep up with our high-speed production line without stopping?

Yes. It is designed for high-speed, dynamic environments. The system uses dynamic tracking technology that locks onto each bottle as it moves, even if it's vibrating on the conveyor. The parallel processing of the AI core ensures that inspection and rejection commands are sent in milliseconds, allowing it to sync perfectly with lines running up to 200 bottles per minute.