V Blenders Guide: Working Principle, Types, Advantage and Tips for Success

Top 10 Liquid Capsule Manufacturers In The World(2024)

Powder Mixer Machine: Types,Production Steps,Working Principle and Features

Powder mixer machines are used in various industries to blend powdered materials effectively. Whether for food, pharmaceuticals, chemicals, or construction, the need for mixing powders comes up in many situations. They ensure consistency, quality, and efficiency in production processes. In this post, we’ll cover the basics of powder mixer machines, the types available, how they work, and their uses. We’ll also look at their advantages and disadvantages and discuss the principles behind them.

What Is a Powder Mixer Machine?

A powder mixer machine combines powdered materials into a consistent, uniform blend. In industries like pharmaceuticals, food processing, and chemicals, where precision is critical, manual mixing can result in inconsistencies. Powder mixer machines solve this issue by evenly distributing all particles, ensuring quality in the final product. These machines also handle large-scale production, which manual processes often can’t manage.

Most Popular Types of Powder Mixers

Powder Mixer Machine Types

Different types of powder mixers are designed to meet specific industry needs. The choice of mixer depends on factors like the properties of the powder, the required level of mixing, and the industry in which it is being used.

Ribbon Mixers

Ribbon mixers feature a U-shaped horizontal trough with a rotating shaft that carries mixing ribbons. These ribbons move powder in opposite directions to create an even blend. Ideal for industries needing to mix large batches of powder quickly, such as food and chemicals.

Real photos of Ribbon Mixers

Paddle Mixers

Paddle mixers use large paddles attached to a central shaft to stir and blend powders. These mixers are gentle on fragile powders, making them a perfect choice for materials that could be damaged during mixing.

Paddle Mixers interior pictures

V-Blenders

V-blenders consist of two cylindrical sections forming a “V” shape. As the machine rotates, powders inside tumble and mix. These mixers are frequently used in the pharmaceutical and food industries to blend dry powders effectively.

V-Blenders product photos

Tumble Mixers

Tumble mixers consist of rotating cylindrical containers that mix powders by tumbling them inside. They are commonly used in construction for mixing materials like cement, where large quantities of powder need to be mixed.

Tumble Mixers real shot

How a Powder Mixer Machine Works?

Understanding the working process of powder mixer machines can optimize production efficiency and product quality. The process involves several key steps:

Step 1: Loading the Ingredients

The process begins by loading the powder ingredients into the mixing chamber. Some machines allow for manual loading, while others use automated systems to handle the powders safely and efficiently.

Filling Ingredients

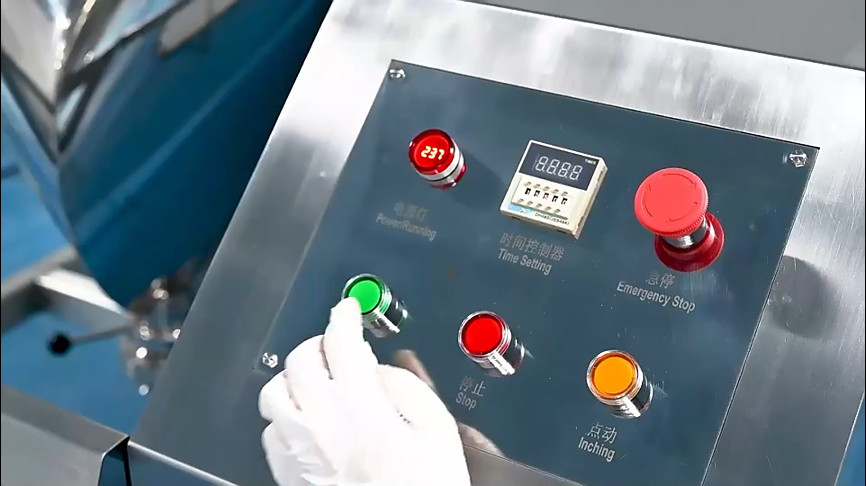

Step 2: Setting Mixing Parameters

Before starting the machine, the operator sets the mixing parameters, such as speed and time. These parameters ensure the powders are blended correctly, depending on their density, texture, and required mixing duration.

Adjust mixer parameters

Step 3: Mixing Process

Once the machine is started, the mixing blades, paddles, or tumbler begin to rotate. The powders are moved and turned over continuously to achieve an even mix. Some mixers move the powder both horizontally and vertically to ensure all particles are evenly distributed.

Mixing and Stirring

Step 4: Discharging the Mixture

After the mixing process is complete, the powder is discharged from the machine. Depending on the machine's design, this can be done either manually or through an automated system.

Discharging mixture

Step 5: Cleaning the Machine

Once the powders are mixed and the product is discharged, the machine must be cleaned to avoid contamination of future batches. Some machines are designed for easy cleaning, which is especially important in industries like pharmaceuticals and food processing, where hygiene is crucial.

After using the machine, please keep it clean

Applications of Powder Mixer Machines

Powder mixers have widespread applications in industries like:

- Food Industry: Blending ingredients such as flour, sugar, and spices to ensure uniformity and quality in processed foods.

- Pharmaceuticals: Mixing active ingredients with excipients for accurate dosing in capsules and tablets.

- Chemical Industry: Creating consistent mixtures for products like cleaning agents, paints, and coatings.

- Construction: Mixing materials such as cement, sand, and other building materials to ensure uniformity.

What Are the Advantages of Powder Mixer Machines?

Powder mixer machines offer several significant benefits:

- Efficient Mixing: Machines can blend large quantities of powder quickly and far more efficiently than manual methods, resulting in faster production times.

- Consistent Quality: Powder mixers provide uniform blends, which is crucial in industries like food and pharmaceuticals, where consistency affects product safety and efficacy.

- Reduced Waste: Manual mixing often results in material loss due to spillage or poor blending. Powder mixers minimize waste by ensuring complete, accurate mixing.

- Scalability: Powder mixers are available in various sizes, allowing companies to increase production capacity as needed.

Disadvantages of Powder Mixer Machines

While powder mixers offer many benefits, they also have some drawbacks:

- High Initial Costs: The upfront cost of purchasing a powder mixer can be steep, especially for smaller businesses. However, this cost is often offset by increased productivity and reduced labor over time.

- Energy Consumption: Operating powder mixers can consume significant energy, especially in large-scale operations. However, energy-efficient models are available to mitigate this concern.

- Maintenance Requirements: Regular maintenance is necessary to keep these machines in good working order. Neglecting maintenance can lead to mechanical issues that interrupt production.

- Cleaning Complexity: In industries like pharmaceuticals and food processing, thorough cleaning is essential to prevent cross-contamination. Some machines are complex to clean, adding time to the production process.

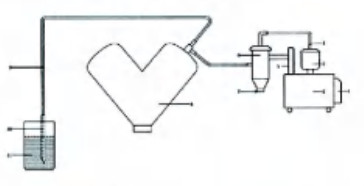

What Is the Principle of a Powder Mixer?

The core principle of a powder mixer is to create uniform movement to blend powders evenly. Different mixers achieve this using mechanical actions like stirring, rotating, or tumbling. The goal is to ensure every particle of the mixture is uniformly distributed for consistent quality.

Powder Mixer operation principle diagram

For example, ribbon mixers use blades to move powders in opposite directions, creating a shearing motion. Tumble mixers rely on gravity to distribute the powders as they rotate. Regardless of the type, the main objective is a homogeneous mixture.

Conclusion

Powder mixer machines are critical tools in many industries. These machines streamline production processes by offering consistent quality, efficiency, and scalability. While there are costs and energy requirements, the benefits usually outweigh the downsides. Choosing the right mixer based on industry needs is essential for anyone involved in production that requires powder mixing.