What’s the Difference Between Hard Gelatin Capsules and Soft Gelatin Capsules?

Powder Mixer Machine: Types,Production Steps,Working Principle and Features

V Blenders Guide: Working Principle, Types, Advantage and Tips for Success

So you've probably seen those huge, upside down V-shaped machines in factories and plants before. They're called V blenders, also known as V-mixers or cone blenders.

V blenders are massive industrial mixing machines used for blending powdered and granulated materials in large volumes.

In this guide, I'll tell you all about V

blenders - what they are, how they work, what they're used for, the different types, pros and cons.

Let's dive in!

What is V Blender?

V blender is a big mixing machine shaped like an upside down "V" or cone, which is why it has that distinct look.

V blenders have a fixed outer shell in a "V" or double cone shape. Inside is a rotating agitator or impeller that mixes the contents as it spins. The V shape provides great mixing efficiency and uniform blending compared to other mixers. The angled sides give better mixing action as materials fall from side to side.

V blenders come in various sizes, from lab models to gigantic industrial units that can blend over 50 tons per batch. They can handle many different dry materials like powders, granules, flakes and fibers.

What Do You Use a V Blender For?

V blenders are made for high volume blending of dry materials in many industries, including:

- Food processing- V blenders mix large batches of foods like flour, sugar, spices, supplements and more.

- Pharmaceuticals- They ensure active ingredients and excipients in drugs and supplements are uniform.

- Chemicals- V blenders homogeneously mix pigments, fertilizers, industrial powders, and other chemicals.

- Plastics and polymers- They disperse fillers and additives uniformly in plastic resins and compounds.

- Minerals processing- V blenders blend clays, pigments and other minerals.

- Agriculture- They mix animal feeds, fertilizers and soil amendments.

The main purposes of V blenders across all these applications are:

- Achieve a homogeneous blend of multiple ingredients

- Disperse minor ingredients evenly throughout a mixture

- Improve product quality and consistency

- Prevent segregation of blended materials

- Continuously blend high volumes of material

Types of V Blenders

There are a few main types of V blenders:

- Standard V blenders- The classic "V" shape with a single agitator. Suitable for general blending tasks.

- Double cone blenders- Two opposing cones joined at the center. Allows blending in two stages.

- Vacuum blenders- Equipped with a vacuum to remove air from products. Useful for air-sensitive chemicals.

- Heated/cooled blenders- Jacketed to allow heating or cooling during blending. Helps mix heat-sensitive materials.

- Charge blenders- Allow ingredients to be charged and discharged while the blender is running for continuous operation.

- Laboratory blenders- Small, benchtop V blenders for R&D testing. Look like miniature versions of industrial models.

The right model depends on your specific blending requirements including batch size, materials handled, level of automation needed, etc.

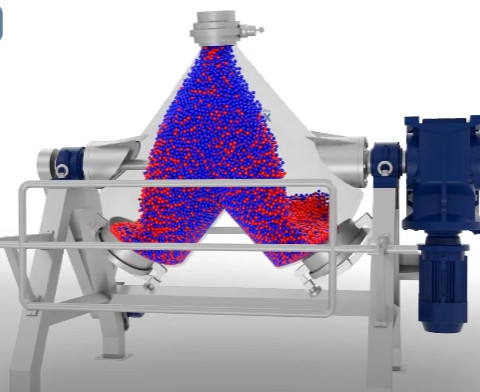

How V Blenders Work

V blenders operate in a continuous or batch processing mode based on a relatively simple concept. Let's break down how they differ:

| Feature | Batch Processing | Continuous Processing |

| Operation | All ingredients loaded at once, mixed, then discharged as a batch | Ingredients continuously fed in, mixed, and discharged simultaneously |

| Control | Precise control over each batch (mixing time, speed, formulation) | Requires precise control of feed rates and mixing parameters |

| Flexibility | Ideal for small runs or frequent formulation changes | Less flexibility, optimized for large volumes |

| Efficiency | Downtime between batches reduces throughput | No downtime between batches - maximizes throughput |

| Consistency | Batch-to-batch consistency depends on process controls | Output must be kept uniform through tight process control |

| Applications | Industries requiring traceability like pharmaceuticals and specialty chemicals | Large-scale manufacturing like food and beverages |

Continuous V Blender Operation

Running a V blender in continuous mode involves these key steps:

Video Source: https://www.youtube.com/watch?v=i4SpP13CjP8

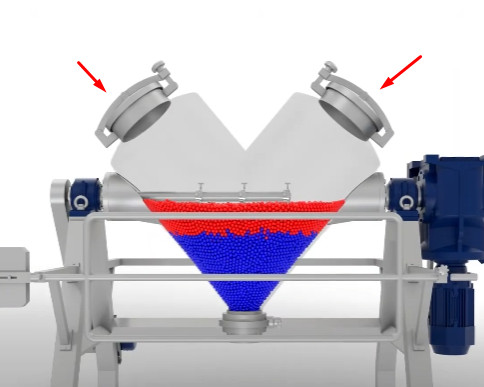

Step 1: dry bulk solid materials are constantly fed into the blender through multiple inlet ports at the apex of the "V" shape. This is done using automated feeding systems like screw conveyors, bucket elevators, or pneumatic conveying.

Step 2: The materials flow down the steep angled sides through the force of gravity as more solids continuously enter from above. Capacities range from 5 cubic feet to over 400 cubic feet.

Step 2: The materials flow down the steep angled sides through the force of gravity as more solids continuously enter from above. Capacities range from 5 cubic feet to over 400 cubic feet.

Step 3: A large agitator shaft equipped with adjustable mixing arms/paddles rotates along the central axis of the blender. Speeds vary from 5-40 RPM depending on the application.

Step 3: A large agitator shaft equipped with adjustable mixing arms/paddles rotates along the central axis of the blender. Speeds vary from 5-40 RPM depending on the application.

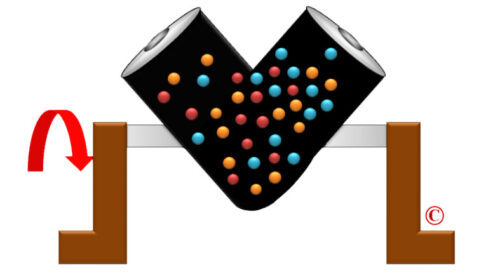

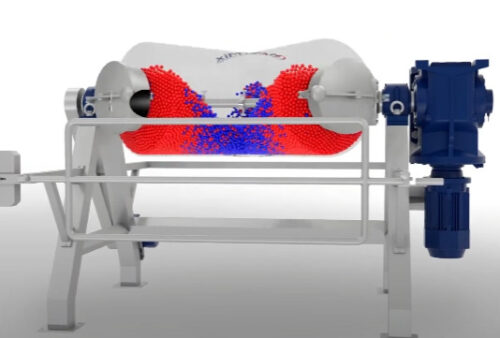

Step 4: When the heavy duty agitator rotates, it creates an avalanching tumbling action - lifting materials up one side of the "V" and cascading them down the other side.

Step 4: When the heavy duty agitator rotates, it creates an avalanching tumbling action - lifting materials up one side of the "V" and cascading them down the other side.

Step 5:This constant top-to-bottom tumbling thoroughly circulates the solids for complete homogenization as they flip from side to side.

Step 5:This constant top-to-bottom tumbling thoroughly circulates the solids for complete homogenization as they flip from side to side.

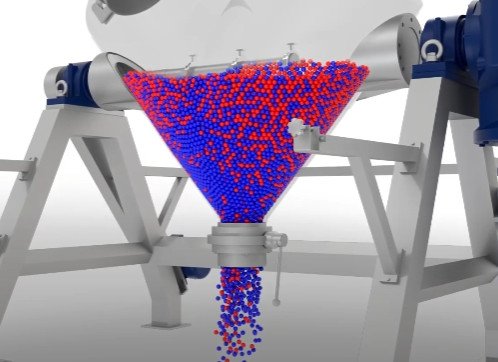

Step 6: The fully blended material exits continuously through one or more large discharge ports at the bottom of the V blender.

Step 6: The fully blended material exits continuously through one or more large discharge ports at the bottom of the V blender.

Step 7: The continuous discharge flow rate matches the continuous feed rate to achieve steady-state blending at the target throughput volume. Discharge is assisted by gravity and can be augmented with vacuum conveying.

Step 8: Adjusting feed rate, agitator speed, blender angle, and other parameters allows tuning the system for optimal mixing efficiency for each application.

Batch V Blender Operation

Here is how V blenders work in batch mode:

- All the ingredients for a single batch are manually or pneumatically charged into the V blender to fill it to the desired capacity. Batch sizes can range from a few pounds to 50+ tons.

- The high torque agitator motor is activated to start the mixing process. Rotation speeds vary widely from 5-40 RPM depending on the blend.

- When the central agitator rotates, it creates an avalanching tumbling action down the steep angled sides of the "V".

- The batch continuously cascades and tumbles, with materials flipping from side to side to thoroughly circulate throughout the blender.

- Once the V blender starts mixing, the blending continues for a preset time until testing shows the batch is completely uniform. This could take anywhere from 5 minutes to over an hour depending on the amount and type of material being blended.

- The technicians have to test samples periodically to verify the blend is homogeneous before stopping the agitator. No one wants to end up with an uneven mix! Proper blending is critical for products like pharmaceuticals where every batch has to meet strict quality standards.

- After the batch is properly blended and passes the required tests, the agitator slowly comes to a stop. Can't have it stopping too suddenly or it could disrupt the uniformity.

- The thoroughly blended material is then completely discharged from the V blender through a valve or vacuum system at the bottom. Some blenders tilt to help empty out every last bit. Spouts and chutes guide the discharged material to its next destination, like a conveyor, storage container or transport bags.

Once all the blended material is out, it's time to reload the V blender with the next batch. The process then repeats - load, blend, test, discharge, reload. Rinse and repeat, sometimes round the clock if it's a high production environment.

The rotation speed, blender capacity, mixing time and other factors are optimized to give the desired mixing results for a given application.

What Are the Advantages of a V Blender?

V blenders offer several noteworthy advantages that make them a widely used industrial mixing technology:

Reliable Blending Action

- The "V" shape provides efficient blending as material flows from one side to the other.

- Blending is consistent regardless of batch size.

- Blends difficult powders better than other mixer types.

Flexible Handling

- Can process batches from a few pounds up to 50 tons.

- Handle a wide range of dry materials from fine powders to granules.

- Many custom options available for specific applications.

Low Maintenance

- Robust, heavy-duty construction with minimal moving parts.

- Basic design allows easy operation and maintenance access.

- Made from materials resistant to wear and abrasion.

Continuous or Batch Operation

- Continuous models allow high-volume production.

- Batch models useful for smaller volumes or unstable blends.

- Can switch from batch to continuous modes in some models.

Easy Cleaning

- Smooth interior surfaces allow thorough cleaning between batches.

- No internal components or gears simplify cleaning.

- Options like wash-in-place systems available.

What are the Disadvantages of V Blenders?

While very effective, V blenders do have some limitations to consider:

Not Ideal for All Materials

- Performance can vary for very cohesive, sticky, oily or fragile materials. May require binders or special configurations.

- Fibers longer than a certain length can tangle in the agitator.

- Very abrasive materials cause excessive equipment wear.

Bulkier than Some Mixers

- Larger floor space footprint than vertical screw or ribbon blenders.

- Not practical for very small batch sizes.

Limited Mixing Action

- Only a basic blending mechanism - may need supplemental agitation for difficult mixes.

- Some ingredients can get trapped in "dead zones" without additional flow aids.

- Not suitable for non-particulate products like liquids or pastes.

Batch Processing Limitations

- Batches must be emptied completely before next batch can be loaded.

- Requires downtime between batches for emptying/filling.

- Difficult to discharge high-cohesion blends through small outlets.

What is the Principle of V Cone Blender Operation?

V blenders operate on some basic scientific principles that lead to their effective mixing performance:

Tumble Blending

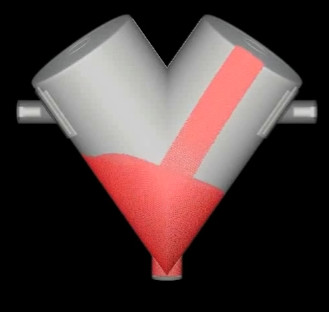

The constant rotation of the agitator causes the solids to be lifted up one side of the "V" then avalanched down the other side. This tumbling action blends the ingredients through dispersive mixing.

Convective Flow

As materials cascade down the sides of the blender, convective flow circulates particles throughout the batch. This turnover exposes all elements to the blending flow.

Shear Forces

The rotating agitator creates shear forces that act on the particles to break any agglomerates and uniformly distribute each component.

Randomization

With each revolution, the random tumbling leads to new particle-to-particle contacts. Given sufficient revolutions, this statistical randomization ensures a homogenous blend.

Powder Flow

The geometry induces bulk flow of powders up and down the V shell. Badly flowing materials can be problematic in V blenders without flow agents.

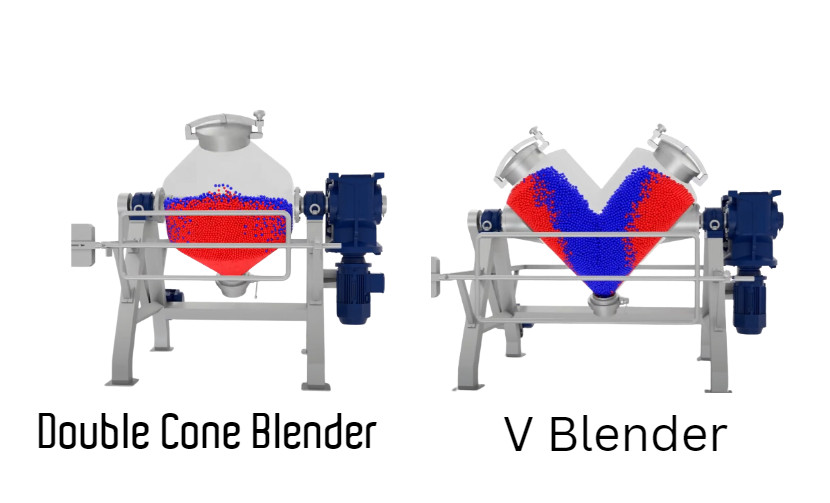

What is the Difference between a V-Blender and Double Cone Blender?

At first glance, V blenders and double cone blenders look pretty similar - they both have that iconic cone shape. But when you dig deeper, there are some key differences between these two common dry blending machines.

Here is a table comparing key specifications between V blenders and double cone blenders:

Specification | V Blender | Double Cone Blender |

Shape | Single V-shaped vessel | Two opposing cones joined at center |

Blending Stages | Single stage | Two-stage blending |

Discharge Method | Bottom or pneumatic discharge | Central outlet between cones |

Typical Capacity Range | 5 - 400+ cubic ft | 1 - 60 cubic ft |

Mixing Action | Vigorous, robust blending | Gentler blending to prevent overmixing |

Typical Applications | Foods, chemicals, minerals, plastics, agriculture | Pharmaceuticals, delicate mixing |

Agitator Design | Single shaft with arms/paddles | Two separate shafts |

Material Flow | Over-and-under flipping action along V sides | Back-and-forth sloshing between cones |

Shape and Design

- V blenders have a single open-topped V-shaped vessel with one agitator mixing the entire batch all at once.

- Double cone blenders consist of two opposing cone-shaped halves joined together at the middle. This gives them two separate blending chambers with a combining section in between.

Blending Stages

- V blenders only have a single blending stage - ingredients are loaded in and get mixed all together in the V-shaped chamber.

- Double cone blenders offer a two-stage blending process. First, components are loaded into the individual cones and pre-mixed separately. Then, the partially mixed batches flow into the combining section in the middle for final mixing.

Discharge Methods

- V blenders typically discharge blended material from the bottom of the V or through a top pneumatic vacuum system.

- Double cone blenders often discharge the final mixture from the outlet between the two cones. Some models also offer bottom discharge.

Sizing and Capacities

- V blenders are available in larger capacities than double cone blenders. Industrial V blenders can range from 5 cubic feet up to enormous 400+ cubic foot units.

- Double cone blenders tend to have smaller capacities since they essentially contain two separate vessels. Typical sizes range from 1-4 cubic feet on the small end up to 40-60 cubic feet for large models.

- For small batch processing under 5 cubic feet, a double cone blender is likely the better choice. Over 10 cubic feet, V blenders offer larger single-batch capacities.

Mixing Applications

- Double cone blendersexcel at delicate mixing tasks common in pharmaceuticals where overmixing must be avoided. The two stages prevent ingredients from being overexposed.

- V blendersare more general-purpose and can handle more vigorous blending. Their higher capacity suits them for larger volumes like chemicals, foods, minerals, etc.

V Blender Maintenance Tips

To maximize performance and service life of your V blender, follow these key maintenance practices:

- Inspect agitator shaft seals regularly for leaks and replace worn seals promptly.

- Lubricate drive motor bearings and other lubricated parts according to manufacturer specifications.

- Check mixing arms and paddles for wear, bending or cracking and replace immediately if found.

- Monitor blender shell, liners and surfaces for erosion damage and repair any excessive wear.

- Remove buildup of material inside blender to prevent cross-contamination and force imbalance.

- Confirm electrical, gearbox and drive components are intact, tight, and properly aligned

- Inspect access doors, outlets and gaskets routinely to check for air leaks or damage that could affect blending. Fix any issues immediately to maintain a proper seal.

- Validate that safety interlocks and other devices are working right, for both personal safety and protecting the blending process. Can't have the machine starting with the door open!

- Test the blending results regularly to verify efficacy. Catch mixing issues early before producing lots of out-of-spec batches.

- Schedule preventive maintenance during planned equipment downtime. This involves thoroughly cleaning, inspecting and replacing worn parts to avoid breakdowns.

Final Thoughts

V blenders are a versatile, heavy-duty mixing option with a long history of handling all kinds of dry materials across many industries. The iconic V shape provides efficient, uniform blending in a relatively low-maintenance piece of equipment.

Investing in a robust, high-quality V blender suited to your specific products, with proper integration into your process and mixing methods, will reliably deliver consistent blends and maximize throughput.