Liquid Capsule Filling Machine NYF-1000

The NYF-1000 automates the difficult work of case hard capsule filling liquid and then sealing it- no manuals. Keeping you ultra-productive.

Integrated Liquid Capsule Production Line (e.g., NYF-300 & NJP-600)

For large-scale, automated production, our Liquid capsule production line is the ultimate solution. These machines, including our NYF-300 and NJP-600 models, are complete systems that combine filling, sealing, and drying into one continuous, high-speed line.

These production lines fill the capsule body with liquid and then apply a micro-band of sealing solution to the capsule's cap-body join. This process ensures the contents remain in a perfectly sealed state during transport and use, dramatically improving product stability and safety.

Develop Your Business with Grand

Features

Advanced Technology

Employing decades of expertise, Grand engineered this novel machine, the NYF-1000, achieves a significant advancement in pure engineering. The machine fills, capsules, and seals at a record pace.

Ideal Applications

Filling solutions, suspensions, microemulsions and hot melts into your capsules. Stability and safe storage are ensured even during transit, especially for highly active drugs with poor solubility. Incorporating more kinds of liquids into capsules.

Superb Specifications

Our exclusive dust collection up to 180m3/hour, absolute humidity fixed at 40-55%, and perfect temperature control within a certain range, render the NYF-1000 suitable for manufacturing both quality and quantity.

Specifications

| Filling Accuracy: | ±2% |

| Compressed Air: | ≤0.6MPa |

| Filling Materials: | 00-4# gelatin, vegetable capsule |

| Machine Weight: | 3000kg |

| Dimensions: | 4100x1300x2150mm |

| Maximum Output: | 60,000 capsules/hour |

| Mold Holes: | 16 Holes |

| Noise: | ≤75dBA |

| Power Supply, Voltage: | 380V/220V 50Hz |

| Total Power: | 12Kw |

Machine Details

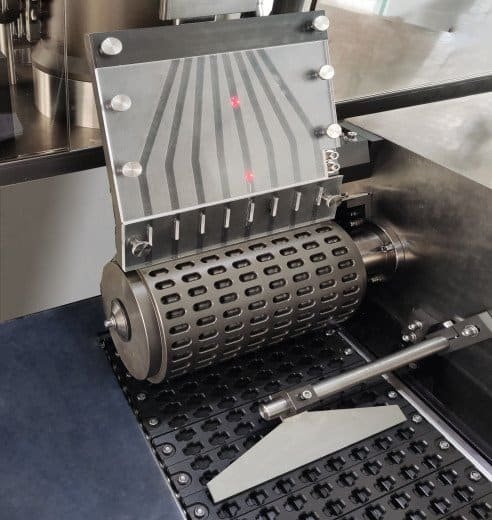

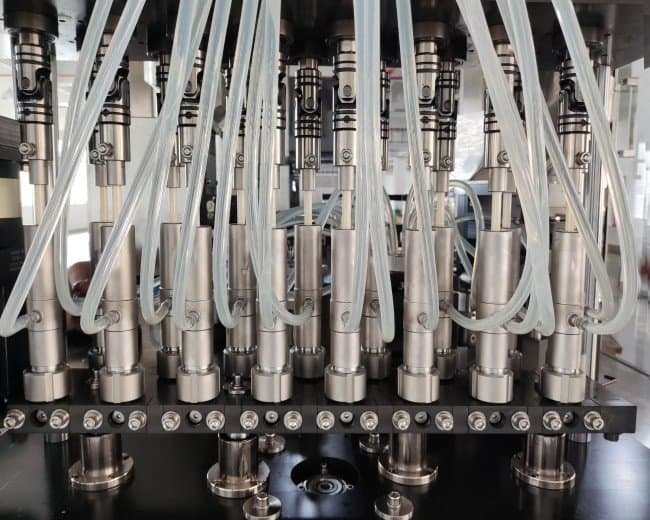

Filling and liquid adding device

New enclosed workbench

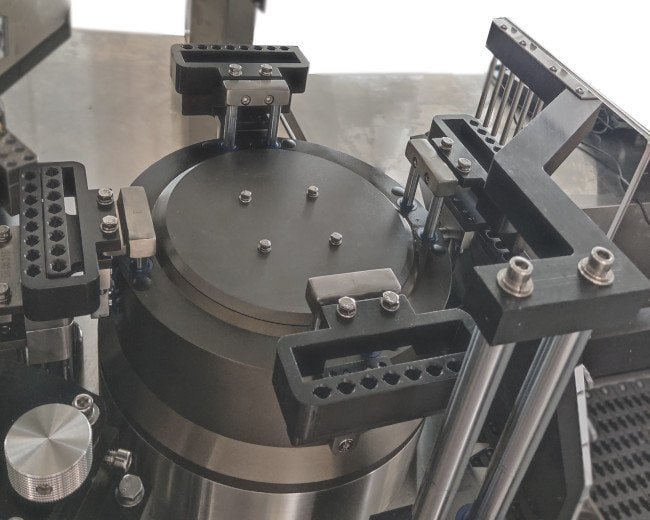

Rotary connection mechanism

Sensor

Working principle